Hi All,

I recently disassembled my machine, moved it and re-assembled it. Jogging and everything is fine. Tonight I went to do my first cut in its new location and it failed during the 3rd step of probing. I thought it might be that I was using an end mill, so switched to a probing rod. Same deal.

Here’s what happens:

- I turn on the machine, it initializes and homes just fine.

- My bit setter is enabled. It asks for a tool measures it and returns to the south center.

- I jog it over to the probe bore, position it and start the probe. (ground connected).

- It goes left, hits the wall of the bore, red. Great.

- It goes right, hits the wall of the bore, red. Great.

- It comes forward, hits the wall of the bore, red. Then when it goes to return to the center of the bore, there is a single pulse of the stepper and probing fails.

I am using Probe V2, Build 566 on Windows 10. I can’t remember if I had run it off this laptop recently, as I was previously using a raspberry Pi that I haven’t had a chance to lug out to the shop yet.

This problem has occurred with the router unplugged, plugged in a different outlet from the computer, and lastly plugged into the same outlet as the computer (thought it might be a weird ground issue).

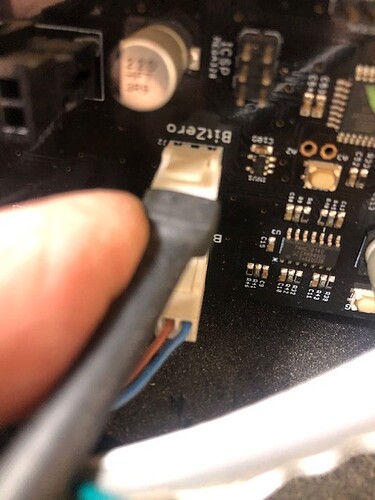

I’ve recorded the oddity here:

Any help would be greatly appreciated!