@robgrz any chance we can get some enhanced probing functions or macro support for probing in Carbide Motion such as:

-

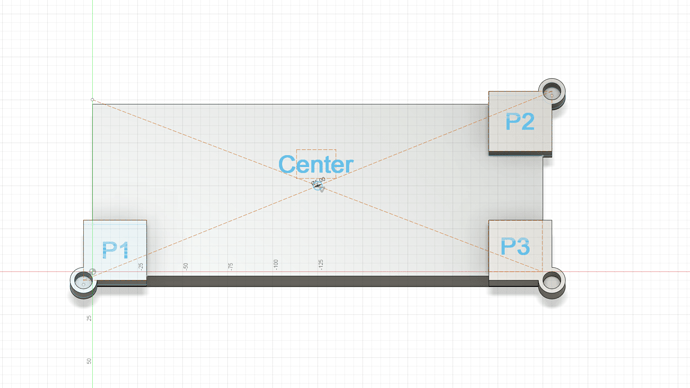

Probe at P1 (Zero) and then probe at P2 to get the delta X and Y (ie. X: 250mm / Y: 100mm) and then either split the difference for X and/or Y which would end up zeroing in the center of the stock so X: 125mm / Y: 50mm becomes the new zero

-

Kind of like bullet 1 but probe different location to confirm workpiece is parallel with the gantry so probe at P1 (Zero) and then probe at P3 to get the delta X and Y (ie. X: 250mm / Y: 0mm) so if Y is 0mm then you know you are square/parallel with the gantry which would help aligning things when flipping a project over and trying to match/align for machining the backside. If Y is not 0mm then you know you are not parallel and need to tweak your setup. I’d use this to set my workpiece backstops (workholdings before starting a project)

Edit: for feature 2 this assumes you are using stock that has been prepared (squared, opposing sides are parallel)