Ok been cutting as much as possible to get experience and ran into this problem. I was cutting a pumpkin trey with 3 pockets out of 41mm red cedar. It was smelling good in my shop. I had it set up for two tool paths one for the pocket and the other for the cutout. The pocket I was using a Whiteside 1372 bowl and trey bit for the cutout the 1/4” square end mill that came with my CNC. I had my stock entered in as 382(x) and 229(y) at 41(z). Zero height set to top. And I may have just figured out my issue but let me know what y’all think. I’m thinking my zero height needed to be set to bottom??? For my pockets my start depth was 0 and max depth was 35mm. When I hit start the bowl end mill started it’s pass about 20mm above the piece. So I had to adjust the depth to get to the desired depth. Was this because my stock zero was measured from the top?? Did the same thing for my contour cut.

Sounds like you set Z-zero to the bottom of the stock in your CAM program ( Create) but to the top of the actual stock in your machine.

So I used both bit setter and bit zero.

As Neil mentioned, you might have selected bottom of stock when you were programing in Create. By zeroing off the top of stock, Motion thought your piece was (x) high not what you actually had, thus cutting air.

But if you set your zero at the top of your stock when your gcode is generated as if zero is at the bottom, you’ll see what you’re seeing.

Does your gcode have negative Z values? If not, you programmed Z-zero at the bottom of your stock.

Personally I use bottom of stock about 90% of the time. Weather you set top or bottom you must zero where you setup said top/bottom. The reason I use bottom is to not scar up my spoilboard. Again it does not matter if you use top/bottom your stock thickness MUST be set accurately. Using the stock bottom I put my BitZero on the spoilboard to set Z zero. If you are using top of material you can set the BitZero on top with the lip on top. You can use the lower corner and do X Y and Z all at once. However I typically use the center of 90% of projects so I put blue tape and mark the center and just jog and set X and Y manually.

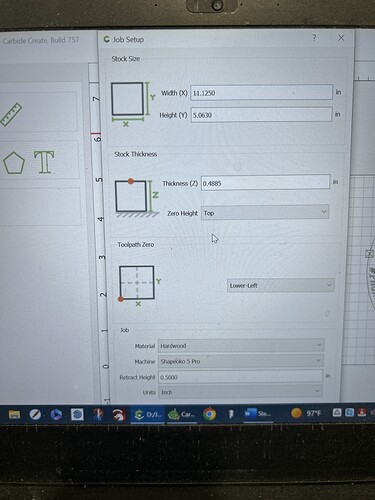

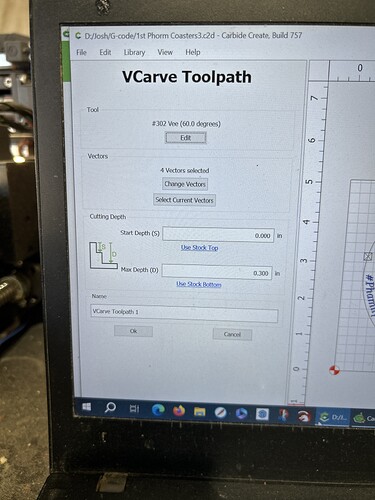

So I got it to work but I had to set the starting height to .05" with a final cut depth of .2" not sure what is going on but i did post pic of my stock set up and vbit set up. I am using a bitsetter and bit zero. I zeroed the work piece and not the waist board

This topic was automatically closed after 30 days. New replies are no longer allowed.