One other general note on making Custom Anything:

DO NOT CHARGE PRICES EQUIVALENT TO OVERSEAS SWEATSHOPS. You are wasting your own time and hurting everyone else’s business.

I had a relative who did custom canvas work for high end yachts. His first 2 years

In business he was super busy but not making that much profit. He learned to price so that he didn’t get every job but made more money on the ones he did.

That will take some experience here.

Absolutely agreed. Experience is key.

My “Go to” finish nowadays is Waterlox - usually the Satin finish. It’s a Tung-oil based product that provides both water and alcohol resistance…while not modifying the texture of the wood. It’s a bit expensive and takes 4 coats to apply - but the application is just an oil finish - wipe it on with a staining pad or brush and let it dry. No worries about sags or dust - it’s very friendly.

My usual finish sequence is:

- Sand through 220 grit (60, 120, 150, 220)

- First coat of Waterlox base finish

- 24-48 hours

- Light Sand with 320

- Second Coat of Waterlox base finish

- 24 hours

- Light sand with 400

- Third Coat of Waterlox base finish

- 24 hours

- Light sand with ‘0000’ steel wool

- Final coat of Waterlox - Satin finish / Gloss finish

- 12 hours

I will usually then apply furniture-grade paste wax using ‘0000’ Steel Wool as the applicator - wait 10-15 minutes - and buff off.

The finish is a pleasure to touch - absolutely no plastic feel (like a poly) but has a lot of resilience and resistance to water AND alcohol. It adds a slight amber hue to the color of the wood - which is usually very complementary to the natural colors of the wood.

- Gary

Try outdoors in Denver, where the air is thinner and the UV effects are greater… Something about living a Mile High vs sea level ![]()

Oh…I get it Mike. I lived in The Springs for 10 years. It’s brutal on a lot of things, but…Your tools never rust and your towels are always dry!

Waterlox, yet another option I’ve just learned about.

Great thread Kev, bookmarked.

And…it comes in a Marine version as well…so, UV protection too.

Does anyone have a suggestion, or multiple suggestions for how to go about making the legs for this 10’ picnic table? Styles and ideas, fastners etc.

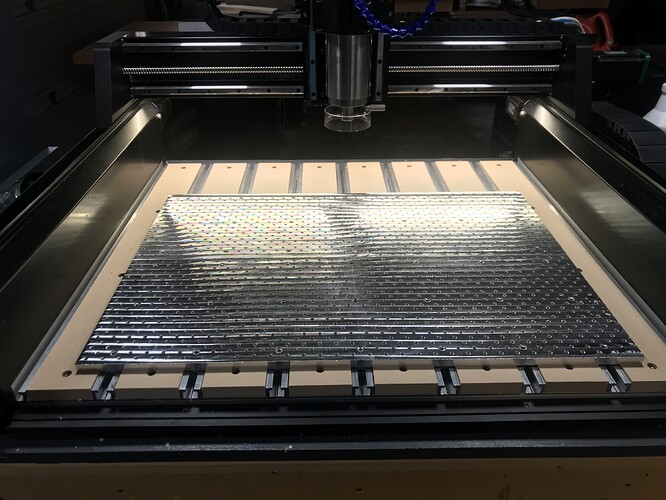

The table top will be c channel with m6 inserts. (Pictures are above in this thread).

Thanks for your time

A traditional Picnic table substructure would be a good starting thought point. Then perhaps a matrix of supports as dictated by the final structure of your top.

I would begin by making the top of the table, since that’s your feature. The final look of that would be instructive as to the needs, both functionally and aesthetically, for the base. Let the top be your guide.

Perhaps metal hairpin legs?

Agreed. The top is the main feature. Im thinking a traditional ‘A’ frame.

I guess my nervousness in making a decision comes from the weght. If the table is being lifted by the top, there will be incredible amount of weight in the legs.

I would engineer the top with that in mind. And that’s another reason to start by making the top, then worry about exact decisions on legs.

Some of your thoughts on legs will crystalize as you build the top. It’s all a process…and remember, it’s supposed to be fun.

Keep on that for sure! @KevBarn14

My inner voice has a perfect word for the reasoning why.

" Dwon’t "…always try and do what others Don’t or Won’t do!

Keep going with the aluminum and bill it as a cribbage board that doubles and a personal defense weapon.

At least finish it… But yeah, you could do a V2 that was lighter as well. Or (I know this is crazy, but…) you could do one that is half & half. I’ld do the playing surface (with the holes) wood, and the bottom (storage part) out of aluminum (but that is just me, keep the CG low with the heavier pc on the bottom).

milling all those 1/8" holes in aluminum scares me haha

I’m 100% behind over-building projects just for the sake of it. I say continue with the aluminum one, but take a page from @wmoy and ISO grid the heck out of it.

To change a saying I like by Colin Chapman to fit my uses here: “Complexify and then add lightness”