Hey griff, what’s the end plan for that aluminum setup? Is it going to stay mounted on the mdf as it is?

This is so true. I have twice gotten an order from something that I made and gave away and I have only been doing this since i received my Shapeoko in September of last year.

Yes…and no.

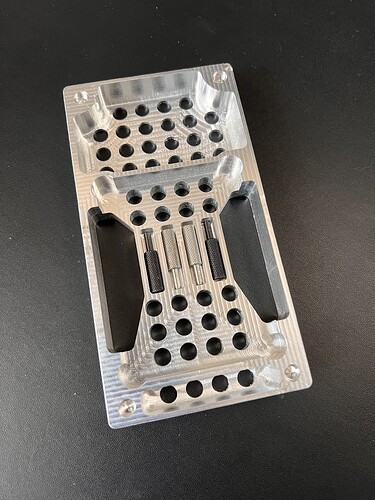

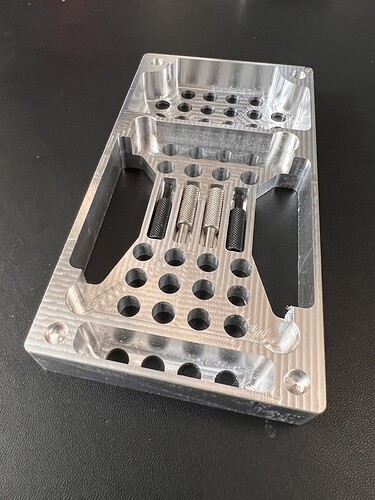

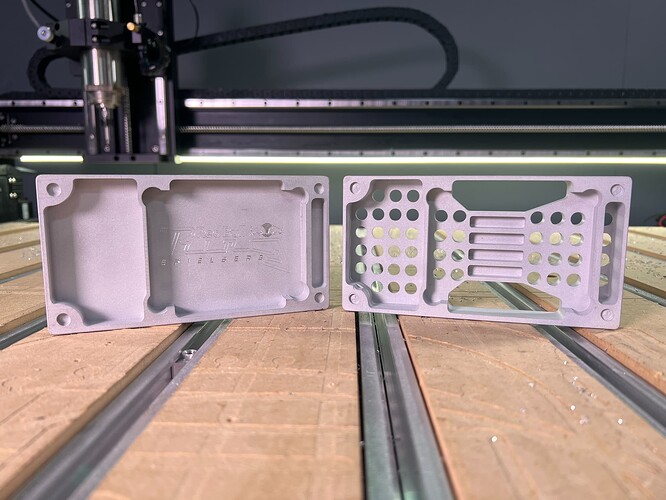

That was my first attempt at a fixture plate for my HDM. It was secured to the t-tracks.

In process now is a .875” one-piece plate that will be secured directly to the HDM frame. Story over here Is milling your own fixture plates worth it? - #59 by WillAdams

On the heels of @Griff saying this was his “First attempt”

How many Iterations is it taking you all to nail down a new design or method?

Do you have an example to show??

My personal number for most projects is generally 3.

2-3 is my average with a few ones in there. The machines and software are so much better than they used to be, that my average has gone down over time.

I’d say your “Rule of 3” is pretty spot on. Generally.

While I’ve nailed some new projects first go, and made a dozen changes to others.

Most take about 3 iterations to get the kinks worked out.

Doing my first project using CC tiling. Let’s see how that goes. ![]()

I surprised myself with this folding step stool, got it on the first try. A rough model in solidworks, ran the extracted dxf files through Vcarve Pro, adding the squiggles there, and generating the gcode from Vcarve. Now, to just clean up the finish.

Beautiful work, well done.

I’d bet a few souls watching this thread would appreciate a step by step. I know I would.

Looks like maple to me

Ok. I feel like this has some legs.

Personal errors have made it necessary to make a 100% new second version, but there are some design choices and thoughts getting worked out here.

An update on the board:

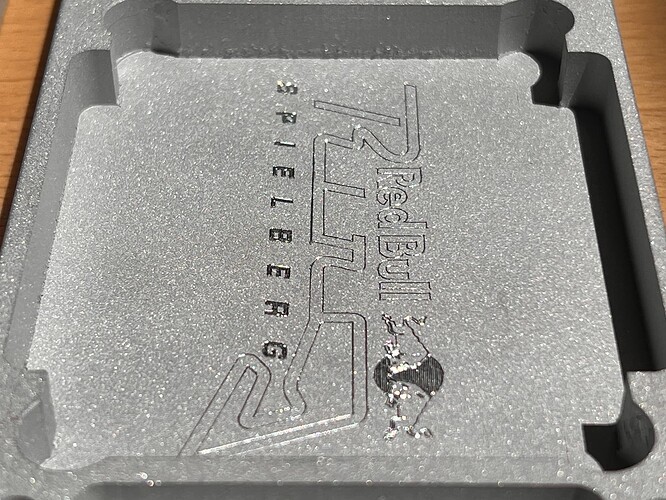

After as much lightening as I could come up with, I thought “Why not have Winston bead blast it”

One day later:

This is all an experiment for this version. Some of the dimensions have been affected through various “I wonder if this will work” events. I like a lot of the features.

What I want is to take the learning from this one on to create a more refined version 2 or 3.

Progression it’s all about progression.

What is your preferred way to finish a metal project??

Sand/polish with 3M Micromesh pads, then polish with Simichrome.

Aluminum:

A - Fine media blast. We have one at work with really fine glass beads that makes aluminum look investment cast.

B - Brushed. Achieved thru tacking down a piece of 220 grit, clamping a board down next to it and using that as a fence to get an even back-n-fourth.

Nice friends projects. Nice way to break up the time on the machine.

My ten foot picnic table is ready for complete sanding today and on to your Penofin tomorrow. Cant wait to see it.

Cedar & Maple Live Edge

Does anyone have an idea for a great signature touch to add to this beast of a table? Bronze ‘name plate’ is all i can think of which is really classic, but im open to new ideas as well. Anyone?

You should have V Carved into one of those top boards.

Watch the back of your legs getting in and out.