Has anyone done double tape method for PTFE sheets? I have a project and I’m curious if the tape will hold well enough or if it will be too slippery.

I don’t see any problem. Try it on a scrap. If you are concerned use carpet tape

I don’t know about double-sided tape, but I did use tape & glue workholding with PTFE a few times with no issues. If it feels too slippery and you don’t care about the looks of the bottom face of the stock, you can give it a light sanding beforehand such that the tape will adhere even better (this and using a roller to make sure the tape is nice and tight against the surface, but of course that only works with tape & glue, not double sided tape)

Blue Painters tape and super glue has never let me down. I use the standard 3M painters tape 1.5" wide. I use the TiteBond Medium Super Glue. The thin super glue does not work well for me and I have not used the thick. The real trick is not to overlap the painters tape but also not leave gaps. If you use too much superglue you will cause the glue to spread and if there are gaps you will glue (slightly) your project to the spoilboard. So it is trial and error getting the proper amount of super glue to stick but not spread out too much. The best thing to do if you have not used the super glue is to put your tape on the spoilboard and on the back of your material. Apply super glue and press the material down and immediately take it off. See your spread pattern and adjust so the glue spreads out but no so far it goes past the edge of each row of tape.

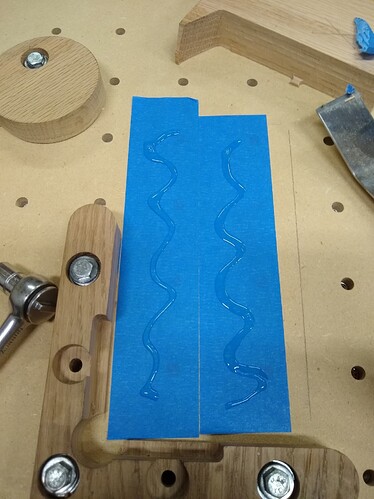

Edit: Here is a picture of my TiteBond Medium SG in actin. This seems to work pretty well for the right balance between too much and not enough.

When I put my material on the spoilboard I trace around it with a pencil. Then I know how many rows of tape to put down and in this example just 2. I could have put down a 3rd row of tape but the think about tape and SG is your project is not going anywhere once the glue sets up. One more piece of advice is to put your material down as soon as possible while you are preparing. With my setup I have found that a minimum of 10 minutes of drying is needed and give yourself maximum time for the glue to cure. So I mount my project and then turn on my laptop, hook up usb, initialize, jog and set zeros, all the usual stuff but that gives my glue a chance to set. Do not glue down the material and start the router. The material may fly off.

I also use painter’s tape, but I use 2P-10 Thick available on Amazon here: https://www.amazon.com/FastCap-Thick-Adhesive-Refill-Ounces/dp/B0006IUWCM

I did at first, but now I don’t use the “accelerator”, because someone here on the forum convinced me it wasn’t necessary. (I have found that quicker drying time [5 seconds] with accelerator has come in handy, but only in a couple of odd clamping situations.)

Another important thing I do, when I add two layers of painters tape and glue under my project, I change my Z-zero by ADDING 0.010". I know that is the correct change in my situation, because I have left a layer of bottom paint on my tape. ![]()

The real advantage to using the “tape and glue” method is that I can design with less wastage. My glued-down project outline can be very close to the final outline, because I don’t have to leave room for mechanical clamps. I save lots of wood that way.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.