Look for PVC sheets rather than those trim boards.

Wow. Ive never had any issues with quality. Sometimes a dent or two on the smooth side from being mishandled. Or staples on the ends but never everything like you found. I always use the smooth side for my projects. I did try running a PVC board through my plainer once, don’t remember why i did that. I think i messed up a sign and thought i could plane it down and reuse the piece. But BOY was that a mess. Planers don’t like PVC. ![]()

![]()

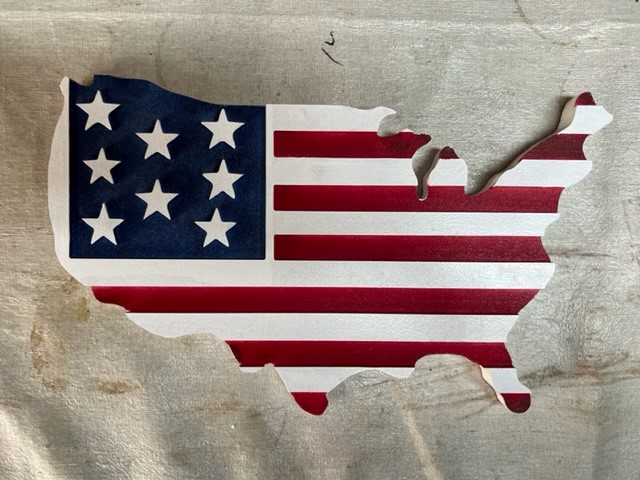

Here’s one more PVC one I did. It turned out to be very popular at the show i went to.

I’ve bought a couple of 4x8 sheets of 1/2" PVC from the Depot. They are foam core. i.e. the surface has a skin of solid material, but the center looks like Chris H first picture above, although I haven’t found any defects in the centers. If I paint the uncut surface I need to scuff with 120 - 220 grit first. If I flatten the surface like for an epoxy poured part, It has to be sealed before applying a finish.

Several outdoor signs are going through their first winter now, so we’ll see how they hold up.

I thought i’de expand my interest a little so i purchased an Atomstack X30 Pro laser engraver. Got it delivered and all put together earlier this week. Now i need to learn how to use it. Going to start with the free LaserGRBL software and see how everything works and then maybe upgrade to the Light Burn S/W. So far im pretty impressed with the quality of the machine, Although i think the learning curve might be longer than i expected. Well see if it was worth the investment. My wife wants to know how much i spent on it. When she does that i always tell her half of what i actually spent and she says thats too much. ![]()

Ouch.

Two things:

- no cutting PVC in the laser — makes chlorine gas

- my father actually kept a PO Box in a separate town for the catalogs and invoices and receipts from his various hobbies — there’s an old joke about this sort of thing, the punchline is, “Honey! I found someone who was willing to pay even more for all of your <guns/fishing rods/boats/hot rods/tools> than you said you bought them for” — a constant refrain of conversation for my father and his friends was, “I hope my wife/kids don’t sell my stuff for what I said I paid for it.”

Definitely looks like you have had far better luck with the pvc boards then i have. The only other thing i can think of is i bought the boards during the height of the pandemic so it was curbside pickup only, i didnt pick the boards myself. Maybe i just got unlikely with the ones the staff chose.

I’ve checked out a few local plastic suppliers and i found one that offers acrylic sheet, both cast and extruded, that looks quite nice at a price i like Also comes in quite a few colours which would be handy to limit the need for painting. Thoughts on using acrylic for house numbers?

Acrylic is a good, modern choice. I don’t think it’s as durable as PVC (more brittle), but it will hold up to weather just fine.

Do you just do the numbers or are you making a complete sign?

I’ve made both. I thought acrylic might be a good choice for individual numbers. I’ll likely try a sign style as well but im not sure how well that will work with acrylic.

The only thing I see with that is you can buy precut acrylic numbers for pretty cheap. I think I’d have to get a really good deal on the colored acrylic to make it worth making my own. Hard to compete with lasers on that mass produced acrylic stuff.

Yeah, i’ve had that thought too. I’m just trying to find something I can source easily that will mill well and make for nice numbers. I think if I can offer different colours and fonts, there still might be a market for that sort of thing. The other use for acrylic I was thinking of is for home decor type stuff like wall art, name signs etc.

Another PVC Design. I changed the design a little from the picture.

Carbide Create Version 7

American Flag With Outline.c2d (532 KB)

This topic was automatically closed after 30 days. New replies are no longer allowed.