I’ve been getting into making custom house numbers for family and friends and i thought i might try making some to sell. Locally first then maybe online. I’ve been using the pvc trim board from the big box stores but I’m not crazy about working with it. I’ve made some nice numbers with it but i find the center of the board can get quite spongy for lack of a better word which has lead to some cutting issues. I don’t think it’s solid pvc. It’s fine for giving away as freebies but I’d like to find something nicer if I’m going to be charging money. I’ve been looking at hdpe boards as a alternative. Not quite as easy to source and more expensive I’m sure but should be doable. I’m just curious if it cuts similarly to pvc, or is it a whole different beast? King Starboard is something i’ve seen mentioned a few times.

So the PVC you normally find is expanded, so you’re right in that it is spongy in the middle. That is to reduce cost. But there is solid PVC. HDPE is a great alternative and I’ve cut a lot of it too. It is pretty gummy, so you definitely want to use single flute endmills and go with a fast feedrate and lower depths of cut to keep it from clogging.

If you have a local plastics warehouse or sign making supply, hit them up. They have a larger selection than the box stores.

While it is absolutely not your question, if you are about to make outdoor signs, I would have a look at Richlite rather than PVC/HDPE, it looks great and is weather resistant (no risk of yellowing/cracks)

I have mentioned this before, if you have a professional plastics near you I have had good luck buying stuff from them. They do have a $50 minimum but I buy full sheets.

They have everything you would ever need with regards to any plastics.

If your lucky like me and have one close, they do have a scrap bin ![]()

Here are a few that I’ve done business with in the past commercially. I think most would service hobbyists/“startup sign shops” ![]()

https://www.grimco.com/

https://www.reecesupply.com/

Find a sign supplier or plastic supplier locally so you can go look at what they have, most of the reps will be very helpful even if they know you just need a few things. Usually will only sell things in certain sizes or quantities, like a 4x8 sheet or whatever. Sometimes they’ll rough cut it for you, but depends on the substrate.

Thanks for everyones input. One other thing i should ask about is painting. I suspect potential customers will ask for different colour options. I know in general plastic can be fussy about taking paint. Is any of the options we’re talking about here a better option for taking paint?

HDPE isn’t good with paint at all. PVC using a plastic primer seems to be the best. The acetone in spray paints seems to make them sick to PVC well. That’s also why the color core stuff is good. The layers make the colors. ![]()

The PVC comes as foam core, sounds like what you have, and solid PVC. The solid PVC would be better. Check online. I have seen that Home Depot and Menards sometimes carry it in 4x8 sheets and some of the other big box stores carry the trim boards. Just make sure you get solid PVC not the foam core.

One way to get solid PVC is to source (offcuts?) of PVC pipe, cut it open, then use a heat gun to flatten it out.

Sorry if this is OBE or off the mark, but thought I would throw out Solid Surface material such as Corian for your substrate. Its pretty tough but machines surprisingly well, has a consistent color all the way through, can be found a wide variety of colors, and holds on to epoxy really well.

I picked up a fairly large piece at Habitat For Humanity’s Restore for around $20 and used a chunk of it to make a house numbers sign a few years ago. I am very pleased with the look and feel. It has held up well to a couple of super hot summers and blistering cold winters.

Hope that helps.

Brian

Wow, that really looks amazing. I did a quick google search and corian seems to be available as countertops in my area. I’m guessing it will be a little too expensive but I’ll put a few phone calls out there. Sourcing material always seems to be a little bit harder for us Canadians. I was hoping starboard/hdpe was going to be my material of choice as I found a few local plastic suppliers who have it stocked at a reasonable price but if it can’t be painted, I can’t really use is for house numbers. The color core stuff Josh mentioned would be perfect but again, having trouble finding it near me. Solid pvc board also is proving tuff to find. Not quite sure where to go next.

Thanks. To be clear Corian is just one brand of Solid Surface material. Silestone, Staron, Meganite are other brands. I’ve seen about 15 other names for it as well. That might give you a few more options in your search.

One other thought I had, but haven’t actually tried, is the composite lumber they use for decking. Seems like it should cut well and be weather resistant.

Good luck in your search.

Brian

What is it about the PVC that you don’t like? It’s used by sign makers and takes paint and ink really well. It’s pretty weather resistant as well.

You can get 1foot square packs of corian. Call some cabinet shops to see of they have some scrap. Corian can be turned like wood on a lathe. Use carbide tools.

I was in commercial sign fabrication for a good number of years. Expanded PVC (like Sintra) is really only meant for indoor applications. It does not have the UV stability and will begin to crack and breakdown in a few years. I loved the stuff like crazy for interior signs, especially with large format flatbed UV and latex printers (Oh how I miss those…). Did lots of print and cut work on PVC for interior retail signs. Exterior, I would stay away from PVC. There’s a reason white PVC pipe must be buried - exposure to UV makes it brittle. With expanded PVC, it’s even more rapid. Maybe painting it would slow that down some - but can’t even tell you the number of signs I replaced that weren’t that old and just broke down because the wrong materials were used.

Now - could you cut 4 or 5 house numbers out of Sintra and paint them and have them last for a really long time? Probably fine, and maybe not something to overthink if it’s your house. Is there better material if this is a product your selling to customers and want to ensure it’s longevity and quality? If you want to be sure what you’re selling doesn’t fall apart in 3 years, I’d call up one of sign suppliers above and ask their advice.

I use standard 3/4 PVC sheets all the time for my signs. They may not be solid core but seems to cut well and has a nice smooth finish on the cut area. Painting using standard acrylic paint with clear coat finish. I’ve had these signs outside for a couple of years with no deterioration of the material or the finish.

This material is made for outdoor house trim so i don’t know why it would not be durable in weather. It is flat on one side and has a rough wood look on the other. Comes in 4 x 4 sheets or boards in 5 1/2, 7 1/4, 9 1/4, and 11 1/4 widths in 4 or 8 foot lengths. But it’s cheaper to buy the sheets and cut to width and length as needed. Royal Building Products is a common brand stocked by Lowes, Home Depot and Menards

Im not sure what everyone is talking about with foam core vs solid core. But the stuff i am buying works just fine for me. And i can imagine cutting PVC pipe and flattening with a heat gun. Sounds like that would be quite a chore and not worth the effort.

Just my 2 cents worth

Those look great Loren!

I’ll eat a little crow on my above post a little. ![]() It looks like their are lots of PVC trim products at the home stores that are meant for exterior applications, guessing they are UV stabilized.

It looks like their are lots of PVC trim products at the home stores that are meant for exterior applications, guessing they are UV stabilized.

I will say that traditional sign making PVC panels, like Sintra brand, are not meant for “permanent” long term exterior signage. Having seen failures of mis-used PVC paneling for exterior signs, I think I was a little traumatized. ![]()

That’s what were here for. To voice our opinion and share ideas.

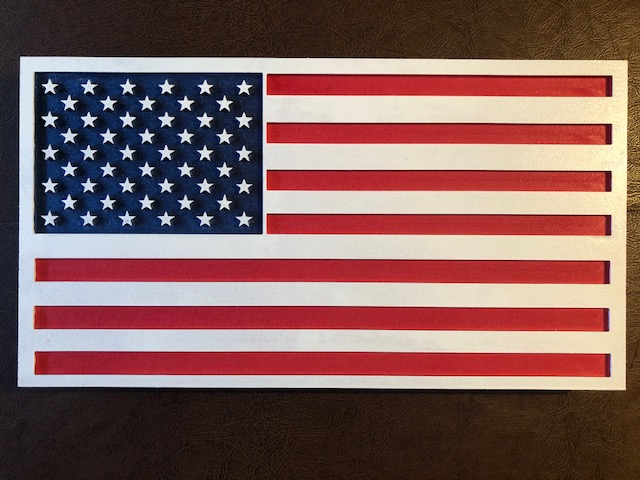

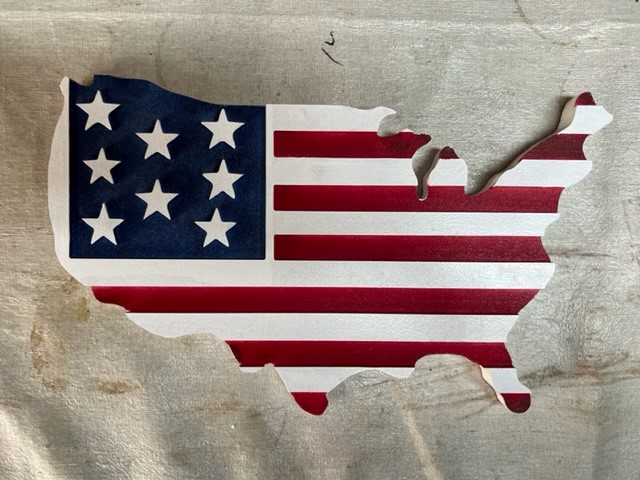

Here’s a couple more I did with PVC

Wow, really nicely done. I’ve bought a few of the royal building products pvc boards from lowes but the quality of them hasnt been great. The grain side is ok but the reverse side is pretty rough. Also encountered lots of holes and voids which caused me some trouble.

In my experience the Azek brand of PVC “lumber” is dimensionally accurate, S4S, and few, if any voids.

A bit pricier than the sheet goods though.