That category though, it’s telling!

Preface – middle of 2022

A few years ago I had trouble with my motion PCB, and had a few long conversations with someone at Carbide3D who had a good understanding of the board and possible problems and solutions. Purchasing a new PCB solved my problem, and I was happy to spend the money to get it back up and running. (My conversation with carbide3d’s support was to confirm my suspicions before purchase). To summarize, they made money on our support conversation, and I was happy with my machine working again–win, win.

My machine has been working for the past two years without issue! Then Friday it disconnected mid cut! No problem, I’ll reconnect, only I couldn’t. I restarted everything and also had to reset the USB ports on my computer, and I was finally able to reconnect–success #1.

I started my cut again only to realize the machine was no longer controlling my spindle. (Aftermarket random Amazon/Ebay spindle and HY VFD–aka unsupported)

I reset everything on the vfd (I don’t believe this was necessary, I manually hit the stop button on the VFD when it turned on spinning, and that usual makes it unhappy, but restarted it, and that probably was the only issue with it).

I tested it in manual mode, and it worked perfectly, full button and speed control–success #2.

I changed the setting over to the appropriate PWM control, moved the jumper to “input voltage”, and connected back to the machine and it all worked! … almost.

I was able to control the spindle speed from the computer through the MDI command again! Success #3 (I’ve run on Carbide Motion from the start.)

BUT, m05 would not stop the spindle!

The command would slow it to about 500rpm. Every other m03 speed command set it to the appropriate speed. I checked voltage on the PWM pin, and m03 S24000 gave full voltage (my spindle’s max rpm), S12000 gave about half voltage, but m05 would only bring the voltage down to 0.15v. Same voltages read with the VFD unplugged and plugged into the PCB.

Normally I’d consider this within margin, but a quick calculation says this is the perfect voltage to get 500rpm. So my VFD is interpreting the signal correctly, and I have control of the speed, but it won’t stop.

I have checked for ground looping and emi interference–no problems–I’m running shielded cables everywhere.

Any ideas? I’m in the middle of a commission for this Christmas season, and could really use extra brain power to solve this one. (I can still run it like a router through CM, but shop time is the reason I upgraded to rpm control in the first time.)

–Is the motion PCB fried?

–Is there a minimum PWM voltage adjustment in either hardware or software?

I’m happy to buy a new board if it’s the problem, but I don’t want to waste money and time if that’s not the problem.

After failing to solve this on my own and consulting an electrical engineer who verified my series of tests to narrow down the problem, I contacted support yesterday. I was heartily disappointed. (Personal info and names have been removed out of kindness for this agent. I have nothing against them, but I feel Carbide3D has let me down.)

Transcript of call/email:

“Hi, this is Josiah. My number is [xxx-xxx-xxxx], and email is ___@gmail.com. My machine, Shapeoko, what is that, the three, shut down randomly in the middle of a cut, and I was able to get it back up and running, but it is not talking to my VFD properly anymore. I’ve done a bunch of tests, and I just need some input and advice on where to go from here. Thanks.”

“Hey Josiah,

I am curious, what kind of tests did you run for your VFD? Also, please send me clear photo of your control board and its connections along with a wide shot photo of your machine.

When did you buy your VFD? I don’t see a VFD or machine purchase connected to the email you gave me. Did you buy it with another email, do you have an order number or copy of your order invoice that could help me in tying a machine and VFD to you to better assist you?

Regards,

[support agent]”

“Hey, thanks for the quick response. I am running a vfd/spindle from before you guys started offering them. It’s running directly off the 0-5v pwm signal. Attached are a couple photos, let me know if you need anything else.

I’ve been running this setup for the past 1-2 years–whenever I got the replacement motion pcb–without issue, 200+ operations without issue. Yesterday a problem code popped up mid-cut, unfortunately I did not get a screenshot of it as I wasn’t expecting problem, but it disconnected from the machine. I restarted everything, and it still didn’t connect, so I reset the usb driver on my computer, and that seemed to do it–random, but I could connect to the machine and move it around.

However, I had no control over the spindle at this point. I would not start or stop from a .nc file, or a direct mdi command. I reset the vfd, corrected the settings again, and it all started working again, almost perfectly. I first tested the control manually from the vfd, then switched the input control over to the pwm input, and I could control the spindle speed again, however, M05 would not stop the spindle, only bring it down to about 500rpm. All other speed commands were correct, or close enough, reading the rpm on the vfd matched up with the speed command, and checking the pwm voltage lined up with the commands, all except the command to stop it, which would leave 0.15v on the pwm pin. Normally I would think this was an acceptable range of variance, except the spindle won’t stop with that voltage supplied, and 500rpm lines up with 0.15v in the 0-5v control over a 0-24000rpm range almost perfectly.

When the pwm cable is unplugged from the vfd, the spindle immediately stops since it is no longer receiving any voltage on the input, and once it is plugged back in, it starts back at 500rpm again. If I change the minimum speed for the spindle on the vfd, the spindle jumps up to that speed, and goes back to 500rpm after setting minimum speed to 0.

To summarize, I have perfect control directly from the vfd (not the problem). I have accurate speed control from carbide motion mdi (not the problem), but m05 does not stop the spindle, or bring the pwm signal to 0v (problem).

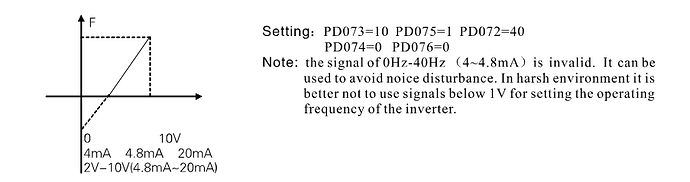

Machine pwm settings:

$30 = 24000

$31 = 0

I have read through every relevant forum I could find regarding pwm, spindle, vfd, and emi, and grounding issues without finding a scenario similar to mine.

Thanks for your help.”

“Hey Josiah,

Try the code m5 instead of m05, if the issue continues after that, I’m afraid we can’t support a third party spindle, you would have to contact the company you bought your spindle from for trouble shooting since the issue lies in a component that isn’t Carbide3D.

Regards,

[support agent]”

“ I tried the command, it did the same thing as M05. It slowed the spindle, but it did not bring it to a full stop, but left it spinning at 500RPM.

Please re-read my summary, the VFD and spindle are functioning perfectly, following every PWM command. The problem is the motion PCB is sending 0.15 volts when the command M05 is sent, not 0 volts. This leaves the spindle running, following the PWM command from the board.

Is the board busted or is the board broken or is there a minimum PWM setting that I can change?”

“ Hey Josiah,

The board may be busted, but the third party VFD is a variable that I can’t account for, you can try replacing your PCB but I’m not sure what effect the VFD had on it or will have on the new one since it wasn’t made specifically to operate with our PCBs. You can try changing the version of Carbide Motion you are using to something more recent since the m5 commands aren’t being accepted but if that fails then yes, try a new control board and see how that works out for you.

Regards,

[support agent]”

“ Hi [support agent],

Please stop trying to skirt your company’s responsibility. I am not blaming anyone or anything, I am looking for knowledgeable help.

I have tried multiple version of carbide motion, as I said, “I’ve done a bunch of tests…” The results were all the same. Both the m05 and m5 commands were sent through mdi, and they were received by the machine (recorded in the log). But, the pwm signal from the pcb is going to 0.15v, not 0v.

The vfd, that you said “wasn’t made specifically to operate with our PCBs” has been running flawlessly receiving commands from the motion controller for the past couple years. It does not “operate with the pcb” as you said, it only receives the pwm signal.

I am looking for more knowledge about the PWM signal on the motion pcb for the shapeoko 3 xxl. If you cannot provide support for this information, please forward me to someone who can.

I realize you are trying to protect your company, and that my request is not a an easy win, but how you handle support for your products tells much about the company.

Please help me solve the problem I have encountered with my machine.

Regards,

Josiah”

“ Hey Josiah,

It isn’t a matter of protecting my company, or seeking an easy win, the Carbide3D team supports Carbide3D products, considering your VFD spindle is the issue and is not a Carbide3D product it is not something we support. Your best bet is to contact the VFD manufacturer, the people that created the spindle that is malfunctioning as there is nothing I can do since the company I am associated with did not produce or design your VFD and Spindle, I have no knowledge of your VFD and my colleagues will have the same level of knowledge and ability to troubleshoot you as I do.

Regards,

[support agent]”

“Do you have ann idea why the pwm signal from the motion pcb would not go down to 0v on command?

-Josiah”

“Hey Josiah,

Could be complications caused by having to communicate with a VFD that the PCB wasn’t made to communicate with damaging the board.

Regards,

[support agent]”

I hate that the first response started with the attitude, “you didn’t buy it from is, it’s not my problem.”

–Am I mistaken in how the VFD receives signal? I’m pretty sure I have a good understanding of it, but please correct me if I’m wrong. I do not believe there is any “communication” between the components, one transmits, one receives, independently regardless of what the other one is doing.

To be clear, I’m okay with an “I don’t know” from support, BUT with some explanation or comprehension for the problem. All I heard from them was, because I used their machine as a “real” cnc machine (before they even released a spindle ![]() ) they can’t/won’t help–along with a complete lack of understanding of my problem, or how their own PCB works. They refused to recognize my problem. (Based on the responses, I’m not sure they bothered reading through my dilemma.)

) they can’t/won’t help–along with a complete lack of understanding of my problem, or how their own PCB works. They refused to recognize my problem. (Based on the responses, I’m not sure they bothered reading through my dilemma.)