Been working on refurbishing the old Stepoko Shapeoko 3 I picked up a bit ago, and it’s definitely a fun project so far. A bit more involved than I expected, but that’s okay. I need to post an update - re-terminated the connections for all the stepper motors, added some limit-switches, and fashioned a z-probe out of some scrap I had lying around - fun stuff.

Anyway, on to my question. I have a 0.5" MDF baseboard that the machine frame is bolted to, as is stock (I believe). I then countersunk some holes for nylon bolts to attach a 0.75" spoil board to the base board. The Sweepy worked fantastically when milling t-slots into this spoil board, I was very impressed!

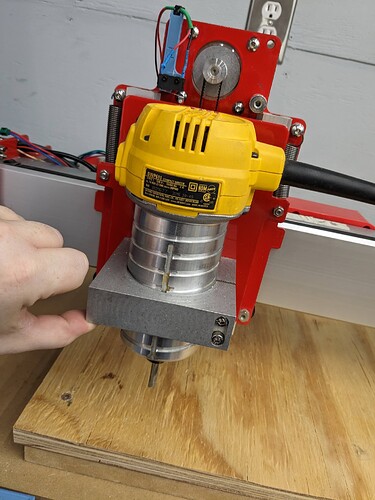

My problem is, now once I put my actual stock on top of said spoil board, I have no room to use the dust boot. I’ll attach some pictures. I searched a bit and saw some suggestions of mounting the base board to the underside of the frame, which I am strongly considering, but that still only gives me an extra 0.5" (plus the thickness of the frame supports, I suppose, but that’s not much) which still doesn’t give me enough room to lower the router in the clamp to use the Sweepy for much depth at all.

I’ve seen people mount their routers as far down as they can go in the router clamp, and I have no idea how they make that work even without an additonal spoil board - seems like that would eat up a lot of z-height. But that is the ideal scenario to use the Sweepy, since you have so much of the router to adjust the dust boot clamp and magnetic fixture up and down.

I just ran a cut in some 0.75" plywood (worked great, first real cut on the rebuilt machine!) with just the upper half of the Sweepy attached, and that sucked up a little bit of the dust, but still made a huge mess, as expected.

Just wondering if I’m missing something totally obvious and if anyone has some suggestions to give me some more wiggle room. I’d love a Z-plus or HDZ, which looks like it would totally fix my issue, but that’s just out of the budget at the moment.

Thanks in advance!