This is total derailing things, hope thats alright Liam.

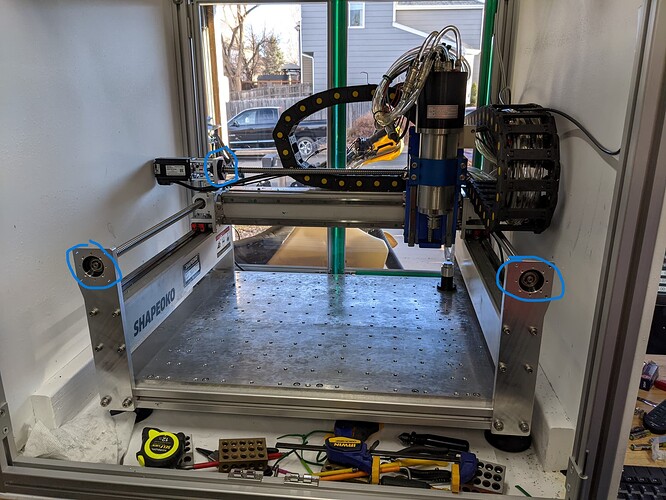

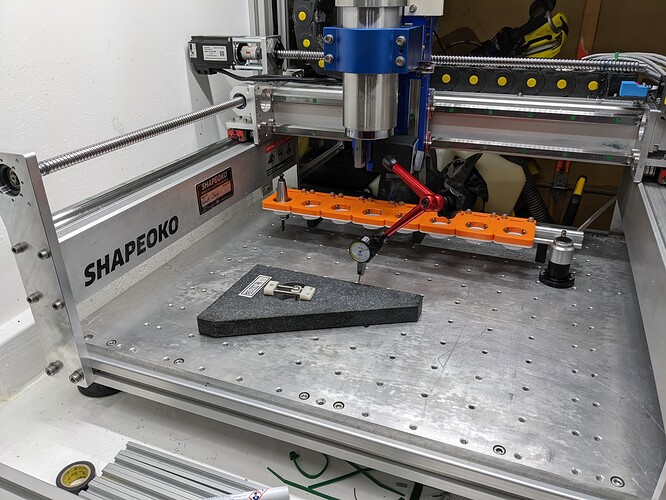

A lot happened the year I got my ATC spindle in hand, first being I couldn’t take my CNC down at the time as I had batches of parts lined up, so that pushed things out which by that time my wife and I were expecting our first child, now 19 months old as of yesterday  and as imaginable reduced my garage/shop time very considerably and still is today. So, the 2 years it took to get the ATC completely operational (not just as a manual quick tool change) shouldn’t be the expected timeframe with one with more dedicated time (and planning)

and as imaginable reduced my garage/shop time very considerably and still is today. So, the 2 years it took to get the ATC completely operational (not just as a manual quick tool change) shouldn’t be the expected timeframe with one with more dedicated time (and planning)

Disclaimer:

I am not a professional, I do not have machinist or CNC operator background. This is still a hobby to me, and I am careful about any job I might pickup but 99% of the time the things I do is only of personal interest and the CNC only typically sees weekend use (less these days :P). I love software development (been my career for over 14 years) and mixing it with hardware electronics and mechanics just add to the satisfaction. So my choices are not always rational or align with someone operating a business, keeping profits, etc. Time is always money, but sometimes I sacrifice that for my joy in tinkering and knowledge.

TL;DR

I do agree, UCCNC doesn’t have ATC support baked in, it has bare bone example macros for it and some others have provided theirs that those inclined could stitch together to work for them. Masso is probably the easiest, Centroid CNC maybe next, and you do pay for that convenience, UCCNC you could walk away a bit cheaper (with their AXBB-E controller) but then maybe spend a little more time in the macros.

When it comes to support, you’ll probably get better/faster response from Masso or Centroid vs UCCNC as well.

Do I regret it? I would say more No than Yes, I wasn’t aware of Centroid CNC at the time but I am in the early stages of a Centroid Acorn build (for a bench lathe) so can share some very limited insights and opinions on that in a moment. I started from scratch for my ATC M6 (tool change) and M31 (tool probe) macros, as I had a workflow I wanted in mind and others didn’t satisfy it. You could easily use the included examples or someone’s shared version to get off the ground faster. During my implementation, I found UCCNC’s API to be … poorly designed and apparent limitations (I do however have high software development standards being a dev myself) that I had to work around as well as hit some bugs (I am running their beta version at the moment so take it with a grain of salt as I hadn’t verified if the bugs exist in the stable version).

UCCNC

What I Like

- 6 Axis support

- Plentiful of Inputs and Outputs

- Different amounts of PNP, NPN, 5v, 24v supported inputs depending on BoB

- Customizable Screenset

- Plugins/Macros are in C# programming language (I have a lot of experience in C#)

- Probe plugin is feature-rich

- Default Screenset is reasonable - though little over crowded

- There is some community Screensets that trim up the Default or complete re-skins that are nice (compared to Mach4

)

)

What I Dislike

- Macros/Automation is limited to C# Macros/Plugins (sub-bullets are gripes that resolve to this)

- Macros can only be in C# not G-Code

- G-Code has no functional support for advanced scenarios (has to be written in C# macros)

- #Vars are not first class, everything is stored in “Fields”, have to call “Buttons” to execute specific actions or check status/states with "LED"s which limits what you can do in G-Code vs C#

- Plugin/Macro API is poorly designed (not to my standards) or incomplete

- Probe plugin/screenset page is confusing and can’t call any of its probe routines in macro without calling the Screenset “Buttons” and changing “Field” values (

)

)

- Screenset rendering does not follow the global standards of UI layering/z-indexing

- Screenset editor can be a little painful I would say it falls below Mach4’s

Centroid CNC - Acorn (I have very limited time with and the build is unfinished)

What I Like

- PLC code runs on the Controller hardware

- Industrial features and company’s background (i.e. ballscrew compensation)

- Powerful G-Code/Macro support, everything (besides the PLC code) is in G-Code

- Acorn Setup Wizard will auto-generate and snitch together the PLC code and Macros needed for most common CNC builds (i.e. ATC)

- Plugin/addon support (and in .NET/C#!)

What I Dislike

- Very limited Inputs and Outputs - you have to buy expansion boards for more ($300)

- Couldn’t have gotten away with the 8/8 IO for the CNC router, I barely get away with it on the lathe by stacking the homing and drive axis fault inputs (which IMO don’t care for)

- NPN only (at least for the controller based inputs)

- Free CNC12 software is too limiting and might as well add the Pro license to your initial cost

- 4 Axis* (not a problem for my lathe build but would be for my CNC router - I have plans for a 4th rotary axis while keeping my independent Y axis pairing)

- “Screenset” customization is very limited (just the “Virtual Job/Button Panel”)

- PLC code would be a little harder to write (vs having C# experience - so little bias :P)

- Acorn Setup Wizard will no longer work in some areas when you start customizing the PLC code or Macros it would otherwise overwrite

*They have shared in the forums a 6 Axis is in the works, maybe with more IO … but more $ than Acorn

MASSO (absolutely no experience, never held it in my hand  )

)

What I Like

- Probably the fastest way to get going

- Tool changer support with setup wizards plus other baked in features easily configurable

- No computer required

- Reasonable amount of IO (Compared to Acorn)

What I Dislike

- High price of entry plus getting charged extra for each axis, touch screen (I think they used to charge extra for the wifi too

)

)

- All-in-one (no computer) doesn’t fit my workflow well and would need one anyway by the machine

- 110Khz pulse rate, this barely meets my 300IPM on the CNC Router and would severally limit the C-axis RPM when I was outweighing it for the lathe build.

In summary, I probably like UCCNC hardware (due to IO) more but UCCNC vs Centroid CNC12 software is still in the air. I have yet to actually run a program in Centroid CNC12 or write macro for it yet.

Edit:

I will also note, I incorporated both ATC sensors in my macros, one detects if the drawbar is in the clamped position (tool holder in spindle), the other detects if the drawbar is fully actuated (petal is open). Using both sensors gives you a lot of feedback that can prevent damage or worse, a dangerous situation in an automatic tool change.

Masso’s documentation suggest only the clamp sensor is used, same goes for Centroid’s docs.

With documentation, UCCNC’s is fine though some things are out of date or require just experimenting to get a better grasp, if you don’t have programming background I could see Macro’s being a huge hurdle. Centroid CNC has some pretty good documentation with example schematics. Their docs can just be a little hard to find/navigate being spread out across several pdfs and the main docs are based on their original/industrial controllers and which you then have to account for the differences outlined in Acorn specific docs.

Masso’s looks pretty good as well, I haven’t had the experience of using it for a build so unsure of any shortcomings.