Hello all - Researching airblast setup for my nomad pro and have a question. Those that mount the airblaster on the right side of nomad, how do you deal with the endstop that is mounted on the top? I don’t think it can trigger if air blast is on the right side or am I missing something?

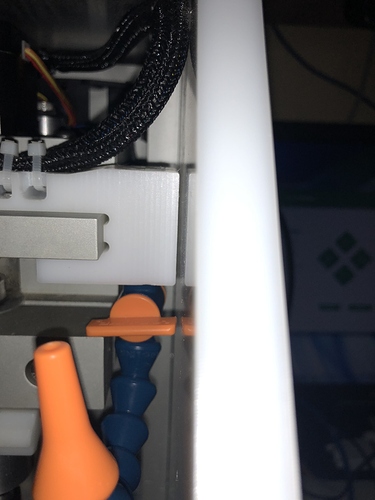

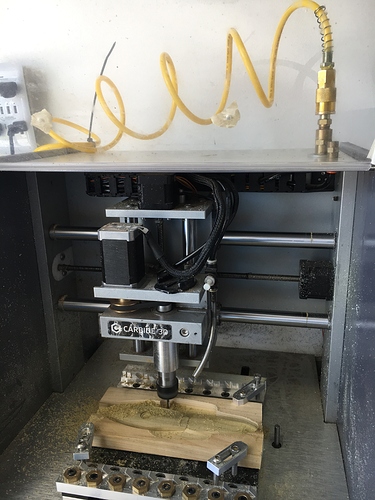

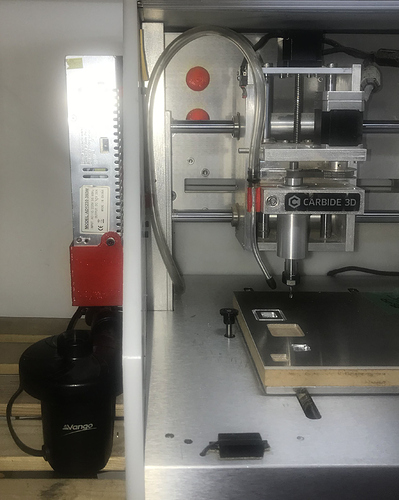

Here’s how mine is; it is on the right side like you asked about. You will need some way to rigidly fixture it to the spindle mount so the line won’t interfere with the limit switches or get jammed in the travel such that it can never hit limit switches. (Machine gets really mad when that happens.)

Line(s) come from the top, route through the cable track and then push to connect line coupler has drilled/tapped mount to the spindle mount. I’ve got a variety of extra lines and nonsense going on because I’ve got an ill-advised minimum quantity lubricant system approximately 80% complete.

Mounting to the right side is nice because it makes routing easier by keeping bend radii large which is worth the extra effort to prevent the lines causing territorial disputes with the x-axis.

Hope this helps!

P.S. I am rocking an ER16 spindle on mine, no, it’s not really a good idea. Spoiler alert 70W really isn’t enough for 3/8" tooling. But when I add that second spindle motor…

Thank you Tony and Phil. I completely forgot about the frame that extends out a bit where the endstop is. going to try this one since i already have a 3d printer: https://www.thingiverse.com/thing:1597589 Going to use a fishtank pump to start instead of air compressor.

Definitely do fishtank pump over the air compressor, you really want pump designed for flow rate and not pressure (e.g. fish tank vs compressor). You’d hardly need any pressure at all to move around Nomad sized chips.

I went with this one

VIVOSUN Air Pump 1110 GPH 8… https://www.amazon.com/dp/B071GN46SJ?ref=ppx_pop_mob_ap_share

How did you mount yours btw?

How did I mount it? With great skill and determination of course!

But seriously, it’s just sitting on the ground, secured only by gravity.

Lol sorry meant to say how did you mount the nozzle ?

Haha

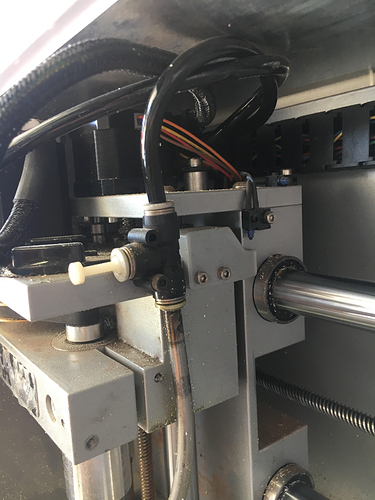

Drive the x-axis as far as possible from home position. Drill and tap a hole into the side of the spindle carriage slide thing. Remember your air line needs slack as it will travel up and down 3" in z axis.

(Bought my Nomad on Craigslist, several attempts were made on the drill and tap operation, as seen in the photo)

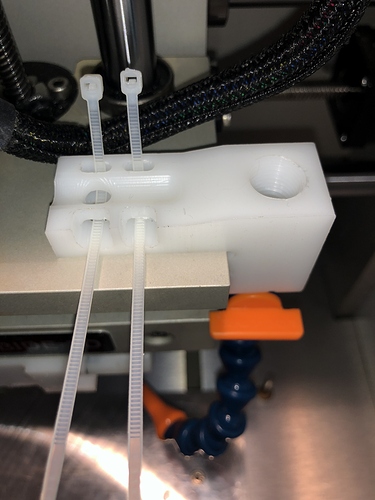

If I drilled a hole every time I thought up something new to mount the carriage would be swiss cheese by now :-). There is already a small hole tapped on the top where the black cable restraint is screwed down to the carriage. The mount I machined has a hole that allowed me to reuse the same screw and threaded hole and a loop to cable tie the black cable to it.

Guess I should put that Fusion file up on CutRocket at some point

Ah got it. That’s just a T connector?

Hey Alex,

You can make it work, I’ve got an aquarium pump feeding my air blast with an aluminum threaded mount on the right side. It’s slim and works.

Ya, t-connector for no other reason that flexibility for future nonsense and I also had a t-connector and plug laying around.

Hi Alex-

I got a US$10 camping air pump <tinyurl.com/y6enterk> - it’s much more powerful than an aquarium pump (but also a bit noisier). I built a simple relay to turn the pump on/off every 10 seconds (to avoid overheating). I slotted the nozzle into left side of the Classic Nomad883 (that would be on the right side of your Nomad Pro carriage) using David’s nozzle gripper <tinyurl.com/y68ucdjd>. I have used it for two years and am happy with it.

Best.

-Peter

I’m sure you must be getting a fair quantity of air to clear the area. The concern will be that it is not made to operate over long periods of time and it will probably suffer from premature failure. You do not need to operate a camping air pump for long to have everything inflated so manufacturers are not putting the highest quality parts in them. If you can fit a computer fan in a similar housing, it could be a solution when it dies.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.