during actual operation it starts high on all 3 pockets so it doesn’t drop down.

hmm yep i do see pocket1 not doing much. not sure why. I got the file from cutrocket.

its this one https://cutrocket.com/p/5ab03cef3912b/

Took a brief glance via the Fusion webapp. A couple things not exactly making sense on the toolpaths in that cutrocket file. Not sure if its a data migration thing or those were the toolpaths that were uploaded. Suggest you redo the toolpaths from scratch if you can. Also triple check the tools and feeds and speeds.

will do thank you. this will probably set me back another week

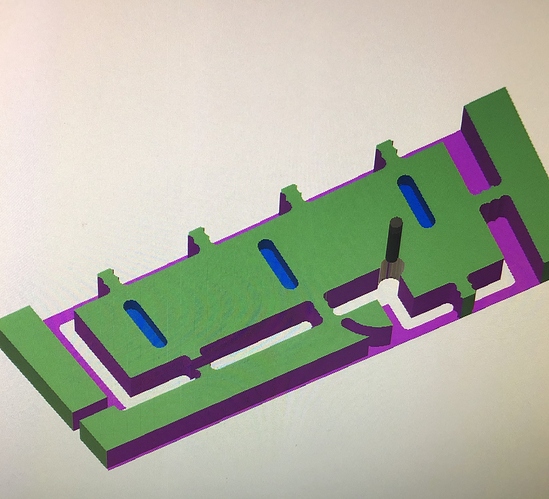

It is amazing how getting the toolpaths, speeds, and feeds just right take far longer than you would think. Just to be sure I downloaded the file and opened in full F360 today. There are quite a few things that don’t add up. The toolpaths with wrong bottom heights, the feeds and speeds look off (to me), the screw slots turn out wrong, the humungous tabs basically mean you will be taking a hacksaw to it, and several parts leave an excess 0.5mm stock on it. Added a picture of what the end result would be from the F360 simulation with stock turned on (if you got through without breaking a stack of end mills)

In the interest of avoiding whatever else is lurking in there I still suggest starting the setup/toolpaths from scratch just so you know whats in there. Time in front of the PC saves broken tools and frustration. Sorry!Thank you for your help. That’s why i said it will delay it  and it definitely makes sense since I can actually learn it instead of asking others

and it definitely makes sense since I can actually learn it instead of asking others

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.