I haven’t tried to do any v carving yet with my pro xl and would like to remedy that. I was looking at the v bits c3d sells but they’re a little more then i wanted to spend. I then saw the essentials vbits and was wondering if anyone here has any experience with them and how they compare with the more expensive vbits?

I’ve used them and been happy with the results. Not sure if their durability is any different, but they work great when new.

Check SpeTool bits thru Amazon. They are inexpensive and seem to do a good job. Been using them for a couple of years for sign carving with no issues.

Thanks for the suggestions. I ended up going with the essential vbits c3d sells, hopefully the will work out ok. I’m super pleased to hear the spe bits through amazon are decent quality, I’ll definitely take a closer look.

My story

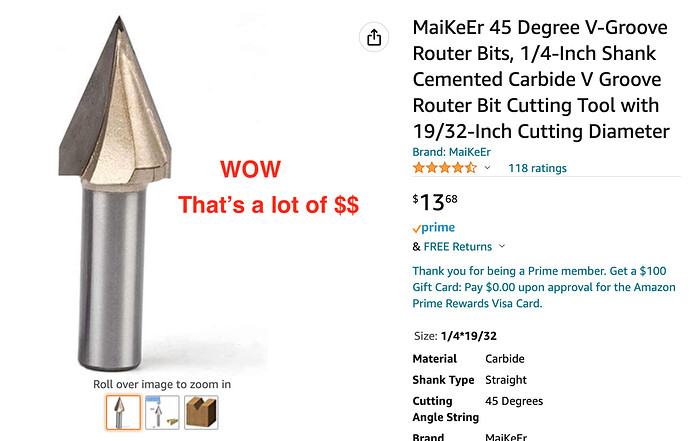

My V-Cutters range from $1 (yes a buck) 30º, 60º and 90º (1/8 shank) and my high end (lol) cutter cost me $13.68. Carbide is CARBIDE on a Shapeoko (Oh there are sharp tools and BADLY sharpened tools from very country, that’s another story.) I have great (and sharp) tools from USA, Japan, Israel and China. ( I have a few bad tools, I usually return them or do not buy from them again).

Don’t be pressured (or fooled) into the idea that a $125 Amana V-Cutter works better…it doesn’t. But people believe that you NEED to spend a lot of money on cutters to make good parts. To that I say…giggle.

Knowing HOW to use a cutter (Good program, speeds and feeds (and a sharp cutter) is 99%. Been in this business for almost 50 years. Now you’ll find the lesser experienced and or lesser educated machinist that will argue with me until the cow’s come home…but day one engineering school…you can’t fix st…

Edit Add: (Background) I started my professional machinist (meaning not counting high-school) as an apprenticeship Tool and Die Maker. I made tools (HSS and Carbide), and sharpened tools. I now sharpen almost ALL my tools (even ball end mills), and I still have almost every cutter from when I first bought my Shapeoko back in 2015.

I really appreciate your input, thanks. It’s great to hear I don’t have to completely ignore cheaper endmills assuming they’re all junk. Lots to choose from on Amazon so i’m looking forward to trying a few.

If I may ask, what setting do you use for pine/softwoods?

I cut metal (primarily aluminum) 99% percent of the time. Although I did take a year off from metal to build this: African Mahogany) desk.

I too have had success with cheap end mills but I’ll be darned if I can sharpen them. Maybe a tutorial Rich?

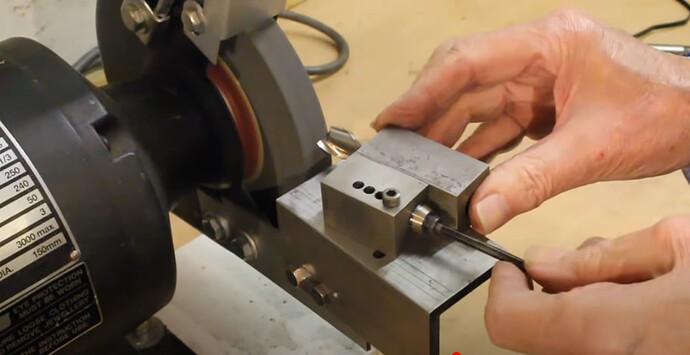

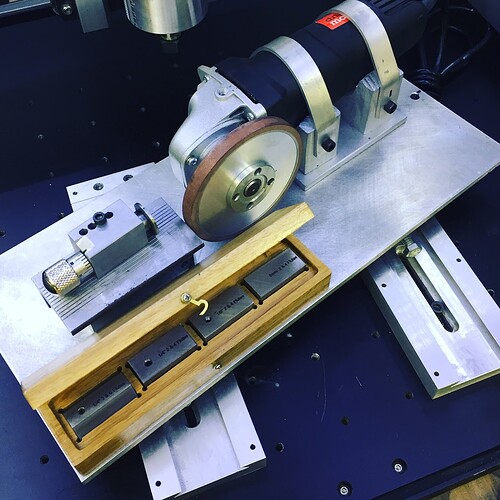

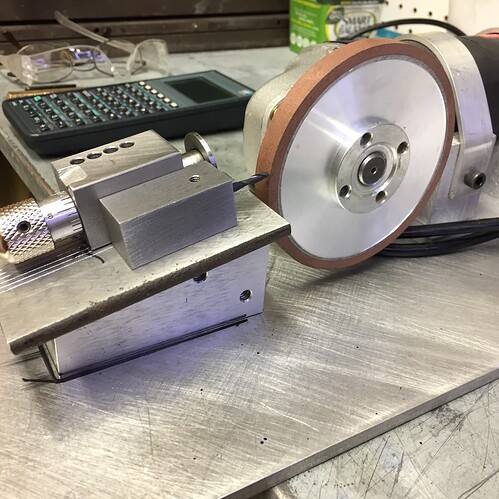

I made/built this:

From this guy:

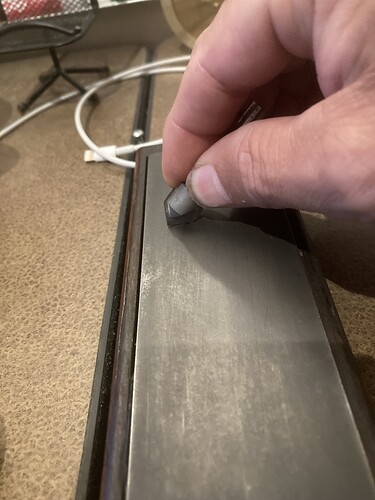

And mounted it to a Diamond wheel since I am using carbide endmills…added a Hex adapter, so I can also sharpen 3 Flute Carbide3D (style) 201 cutters.

HOWEVER… If I am cutting steel (Usually roughing out a part for the lathe) the tips of my $1.00 1/8 2-flute endmills will lightly dull the tips…and Since I am only roughing…I will sharpen them by hand…they are usually NOT very pretty, but for roughing steel…they just need to remove that tiny dull spot to be re-introduced into the roughing end mill queue. (Like touching up the tip of a dull drill bit). THIS is more an art than a science. Time, patience, a GOOD pair of 3.50 reading glasses…Like getting to Carnegie Hall…practice…practice…practice…

My end mill (only sharpens the bottom) sharpener.

Photos:

Thanks! Way beyond my skill set but interesting to know.

You CAN do it!

Silly must be 20 character reply…WHY?

Maybe after 20 or so more years of dedicating myself solely to this machinist hobby. Too much else to do plus I doubt I’ll live to 92 lol.

I sharpen my V-Bits (as well as drills & end mills) freehand. I don’t have a cutter jig.

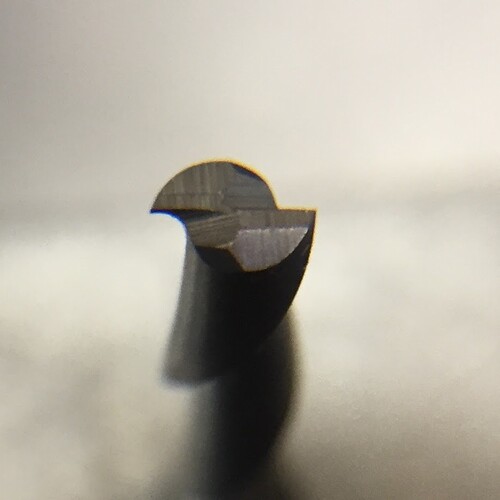

For a V-Bit, you can see (in good light with the right angle) that the backside of the cutting edge will get worn, almost like a really tiny fillet/round. I’ve swiped the back edge with a sharpie just to see it better. (sorry pic is a bit blurry, but you’ll see it in good light, with the appropriate vision correction as Rich mentions ![]() )

)

align the cutting edge up with your stone, and roll forward until the edge touches the stone. You want to make sure you are riding the cutting edge on the stone. You can roll forward just a tiny bit more, but not much 0.5° - 1°.

Then just sharpen & check the edge until the tiny fillet/round is gone.

This topic was automatically closed after 30 days. New replies are no longer allowed.