@mtnjak , if this is a utility robot and not a battlebot, I wonder whether it might be possible to use Dibond (3mm thick sandwich material with thin aluminum skins and plastic core) rather than using solid aluminum with the extensive lightening holes. Or will the holes be also used for ventilation? That would greatly reduce the machining to just the outline and the necessary thru holes…

Those are technical questions that I’m not familiar with. I could pass this along and see what he thinks.

Well, my first cut didn’t start off too well. I used these settings for the 274 bit but seconds into it the bit snapped. Perhaps this material is too industrial for my application? I have no idea what type of aluminum this is. I’m using an 1/8" bit on 1/8" thick material.

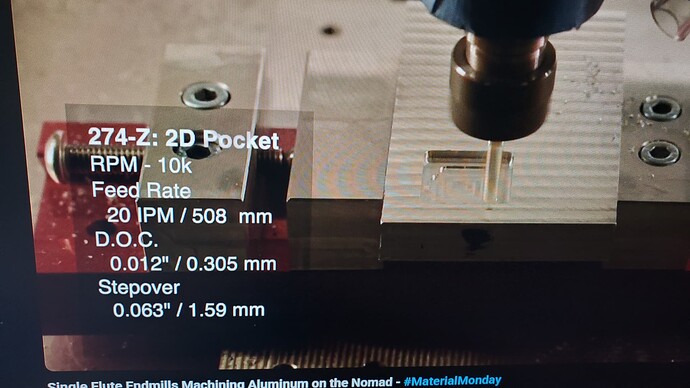

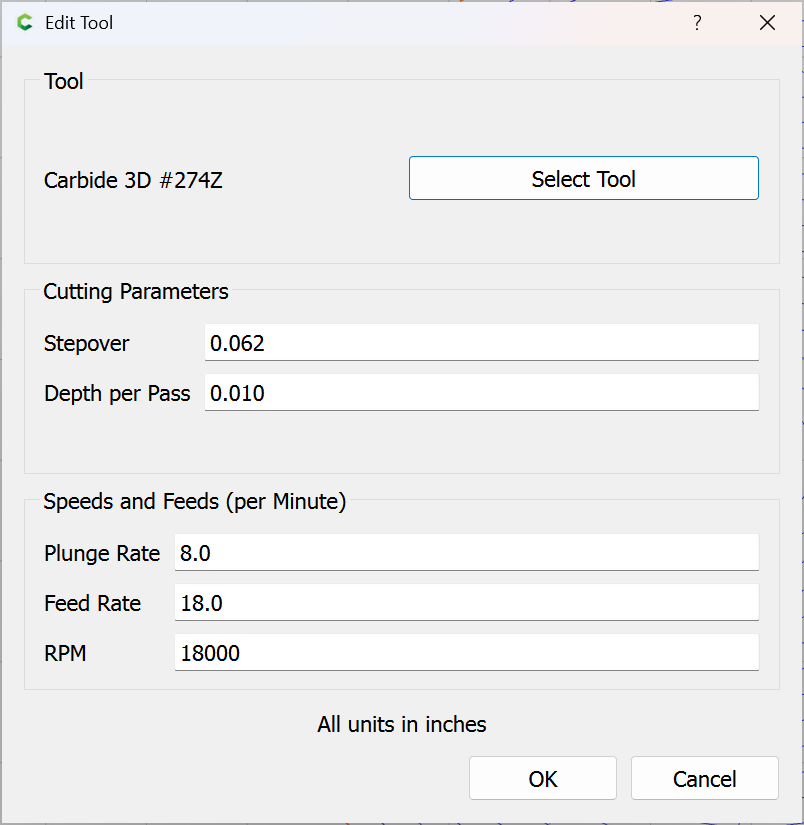

Our recommended feeds and speeds for aluminum w/ a #274 are:

Ramping in will help if you have Carbide Create Pro — check to make sure which alloy you are cutting.

Probably just the photo but it looks like much more than a 0.012 DOC?

If it were me not knowing the material source i would have halved the DOC you listed to start with. It’s always easier to increase F/S’s after you know what the cut looks like, the spindle sounds like, before you break a bit.

Material looks soft and not clearing the bit very well.

What ramp angle would you use ? 2 degrees is the default in Fusion.

My new bits are still in transit.

I have the basic Create software so I don’t think it has the ramp feature.

I have Fusion, so I do have the options, just not sure of the values.

So it looks like, when I convert from mm to in, my cut was a little too deep (0.31mm) and and rpm was a lot lower (10,000) than the speeds and feeds shown above. For reference, I was using a Carbide video from 6 years ago for the Nomad. I think the combination of too deep and the material machining quality seems to be the problem (concluding this after I watched this video by Winston https://youtu.be/rm-qSytjFnI?si=sbQ9lgX5qnsL92RO). Looks like I’ll have to see if my coworker friend can get me some better material? I purchased two bits so hopefully I can make it work with a 2nd try. He’s willing to at least pay for supplies. I’m not sure I’ll charge him much in the end because I was wanting to help out his son (my son is in robotics as well, at a different school).

I would try aviation Aluminium. Doesnt burr up or clog your bit.

What is the recommended Ramping angle I should use ? I am using 2 degrees, seems a bit conservative. 10 ipm

General wisdom seems to be 3-10% for non-ferrous.

Here’s one of the better videos I’ve seen on the subject, can probably skip to 3:40 it’s about helical interpolation but a lot of is about linear ramp angle as well.

(The “In the loupe” series seems pretty solid all around)

looking at the photo, it looks like it was ploughing through or gumming up or rubbing. You mention the RPM was slower (10k) but what was your feed rate?

on a 5 pro 0.31mm DOC should be fine.

Feed rate was 20 IPM

0.05mm feed per tooth is quite hig for an 1/8" cutter especially when you are slotting and the DOC is high.

The ragged edges look like either the cutter was dull/damaged or the metal is particularly gummy.

I set the values based on the Carbide screen capture above. I think poor material is half the problem though. I’ve notified my coworker and he’s going to try to get some better material.

@mtnjak, if the material truly is 6061-T6 as your initial screenshot shows, that is probably the best structural aluminum grade to be machining. 7075-T6 is a stronger alloy and if anything, machines “crisper” but it is harder than the 6061 (in fact as hard as some free-machining stainless) and needs to be machined slower.

[edit]The other common sheet aluminum is 5052-H32. Much softer and can be punched and bent easily, and is used for electronics chassis etc. But horrible to machine other than drilling holes thru…

I have been cutting my first Aluminum project and the results are good. I am getting used to the noises.

I learned the bar stock is not always flat, so I faced off the stock that would have mating surfaces.

I initially used the single flute 274z, but went to the 201 bit ( cheaper bit ) and it looked better.

I did use up a 274 and 278 bit.

The 278z bit started going noisy around 10k inches of machining. I stopped using it around 14k inches because it got noisier and I started losing dimensions.

A lot of the cutting was .270 wide slots in 1/2 thick material.

I know bits don’t last forever. Does this sound like a reasonable use time ?

I used 36 ipm, .015 DOC, .025 stepover, 2 degrees of ramping 10 ipm

All good, just curious.

What was your RPM? Good tools should last a very long time when cutting aluminum. I guess I have never measured how long mine have lasted but I would guess that I have some tools in the 70k+ inches of distance cut.

EDIT: Also, are you using a spindle or a router?

Makes sense. Single flutes don’t typically have the best floor finish unless you get some fancy ones.

Oops. I knew something was missing 18k rpm with a 65mm v1 spindle