A guy I work with is in need of some machining for his child’s school robotics robot they are building. He’s asking if I can cut out something similar to what is shown here. I’m barely familiar with machining wood as I’ve only had mine for about a month. I’m much less familiar with machining metals. Would this be possible with the correct bit? The material is T6 aluminum, thickness is 1/8".

Yes.

I would watch Winston moy videos for tips on feeds and speeds.

Choose something like aviation aluminium, probably has a reference number, to get good chips. In fact this is crucial in order to not break your bits and avoid thick edge burrs.

I have milled between 2 and 8 mm aluminium without ssue with 1mm, 2mm, 3.175 mm and 6.35mm bits with out issue.

Hold down using blue painters tape and ca glue.rub the tape onto the waste board and aluminium if out intend contour cut holes else they will come loose and jam your bit.

Take care with holes 2mm bit can cut 2.1mm hole with out helix lead in.

Be patient. If your learning don’t push the feed, else you’ll end up with broken bits. Feel your way in. Test on small sections.

Aluminium is very satisfying to cut if using the right grade.

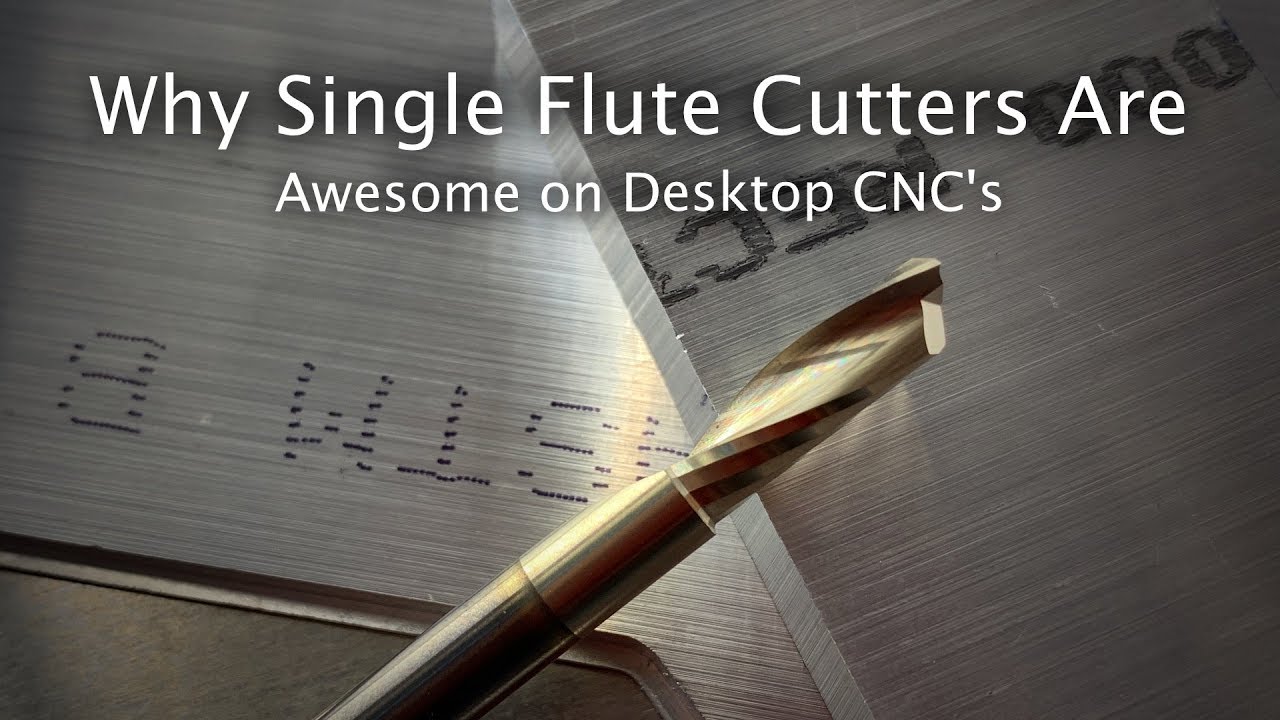

I found single and flute bits best , with coaings

Yes, 6061 cuts well on the machines.

We have videos on cutting aluminum at:

Yes it’s totally doable. The speeds and feeds in Carbide Create are decent to start with, but if you want to be extra cautious just reduce the depth of cut by like 30-50% - keep the feedrate the same though.

But one thing to consider: That’s a decent sized sheet of metal, and you should think about how you’re going to clamp it, or maybe if you want to use adhesive workholding. It may start vibrating in the middle if it’s not supported well. Cutting out the holes in the middle first and working your way outwards may help.

If you don’t have compressed air available when you cut the small holes, you can also use a dust shoe. Anything you can do to get chips out of tight features will prolong the life of your endmill.

I’ll check this out. Thanks for the info guys!

That part would likely be a good candidate to have laser cut versus milled. You may be able to find a local outfit that is willing to offer a discounted rate given that the part is used for an educational activity. Otherwise, there a handful of online outfits that are fairly competitive on pricing.

Good shout, laser cutting should be leveraged more often.

Something I’ve been wanting to play with more is getting materially roughly laser cut and then cleaning up/finishing the tolerances on the mill.

It always blows my mind when I can source a laser cut part for marginally more than the raw material cost ![]()

So, with metals, I want to blow the chips away not collect them? I don’t have compressed air at the table so I would need to do that manually with my air compressor during cutting.

I have used (abused?) a Sweepy to collect chips on some pretty long aluminum cuts, and even added a second cyclone to my vacuum to collect the chips, so one datapoint indicates that vacuuming can work well.

Blowing chips away is the best option, but if you don’t have that, using a dust boot when cutting thin metals isn’t bad either. The important thing is that you get the freshly cut chips out of the way of the cutter.

For the first 1/16" of cutting though, the channels that are being cut are so shallow that they’ll probably be flung away by themselves anyway.

Are you cutting the aluminum dry ? No coolant ?

Good question. As a newbie here, I don’t know. What do you guys do?

In my experience the cooling can really help with surface finish but beyond that it doesn’t usually provide much. Doesn’t make anything tremendously easier or anything like that, just a nice to have.

That said, if you’re doing really precise fits the coolant can be impactful but from my time in high school robotics, we weren’t doing anything close to that kind of precision ![]()

Echoing what Jim said (which is echoing what Winston said) you’ll be fine cutting dry. The single flute does help quite a bit though, if you don’t have one I’d recommend picking two up somewhere.

There’s a saying that if you buy one tool, it’s guaranteed to break. Buy two and you’ll never break either ![]()

Finally, completely off topic design thoughts…if they’re cutting all those holes all the way through just for weight savings, they can keep a lot of additional strength by keeping just a bit of metal instead of cutting all the way through. It’ll also make work holding much easier for you as you’ll be able to use adhesive/blue tape across the entire piece.

(Thanks @wmoy for the tidbit of strength to weight knowledge…I think from an old frankenoko video ![]() )

)

Yep, I have to try this. I have some parts and material ready to go.

I was going to ask friends, but this should work.

I have been trying to avoid coolant.

I got two single flutes on order. My coworker friend found some scrap in the building next door at work and gave it to me to practice with. Thanks for the tips!

Nice! It’s super doable and the community is great about helping solve individual problems as they crop up so you’re set up well for success.

On the notion of scrap, just be aware that the exact material has a tremendous impact on machinability.

Most aluminum feels pretty similar in hand but some cuts beautifully and other cuts like bubble gum…if you have a terrible experience and things don’t seem to be working like everyone says they should, it might be the mystery aluminum ![]()

Worth a shot though and if you or your friend knows the exact material, maybe ask him to keep setting it aside for you going forward ![]()

I just bought a 1/4" and 1/8" single flute bits from the C3D store.

@wmoy What are your recommendations for the 1/8" bit in 6060 T6 aluminum ?

I believe your examples in the video were 1/4 "

Edit: I checked CC and found the 1/8" feed rate is 50% and the DOC is 60% if the 1/4" specs.

1/4 = 18K rpm, 36 ipm .015 doc

1/8 = 18k rpm, 18 ipm and .010 doc.

Ok

I forgot a question.

Conventional or Climb milling expected ?

Edit: I just made a couple of tools paths … Those DOC numbers make for a long run.

1/4" 6061 T6 AL, 1/8" DLC 3 flute end mill, slotting with 0.044" DOC, 22,000 RPM, feed 130IPM, 15 deg ramping, mist coolant:

As you can see, the HDM is quite capable of light production work in aluminum.