I’m trying out CC Pro with a new type of project. The initial CNC time was five days! But my feeds were ultra conservative after breaking bits in MOP, I’ve got the time down to 36 hours testing with increased feeds in the polyester resin substrate. I can get that down substantially more by increasing the plunge rate and I’m wondering if ramping will help.

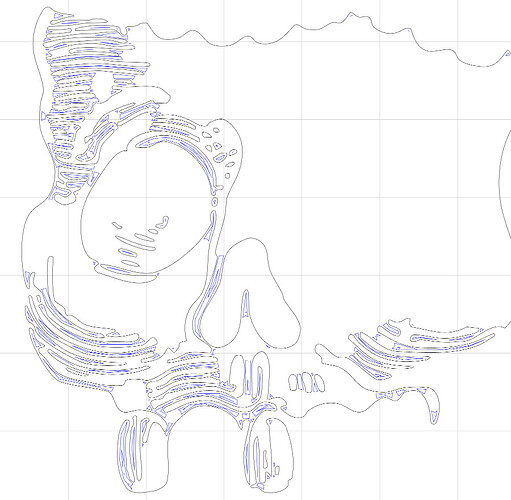

The finest bit I’m using is 0.254 mm diameter, its path is blue in the screenshot below. I searched the forum, one poster said he’d asked ChatGPT which stated that ramping was more stressful on the bit. Huh? The D here is 1.20 mm with a DoC of 0.20 mm. Would ramping help me increase the plunge rate here? If so, is the 20% default the way to go?