I have tendentious in my right arm. So shaking rattle can paint aggravates it. I did not come up with this idea but saw it somewhere on the internet and cannot credit the creator.

This tool has been very useful to me because I use rattle can paint a lot. You need 3 things.

- A drill, I use a Dewalt Cordless Drill but any drill will work.

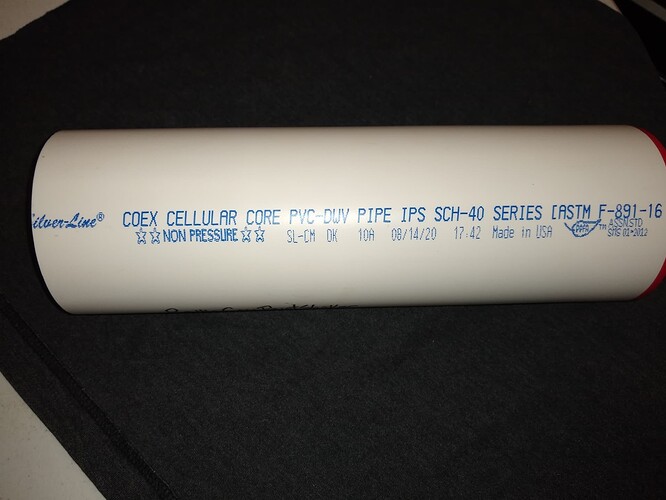

- A piece of 3" PVC Drain and Waste Pipe. You can buy small sections at the big box stores so you dont need to buy an 8’ piece.

- A 3" Drain and Waste Plug. I used an Oates 33402. The bolt and nut you see are used to seal up the DW pipe. You insert the waste plug into the pipe and tighten the nut.

To use the paint shaker you use a piece of old T-shirt cut into a square. You start wrapping the t-shirt around the paint can one revolution. Then tuck in one side of the t-shirt and roll another revolution and tick in the other side of the t-shirt. You want to stagger the tails so the paint can fits down inside the tube. This works with tall cans and regular rattle can paint and primers.

Then chuck up the bolt in your drill. On most battery operated drills when you get the chuck tightened you can spin the chuck back till you hear a click. This locks the chuck and keeps the chuck from loosening during stopping the spinning.

Then put your drill on the drill setting (maximum torque) and set the speed dial to 2 for a fast turn. Start slowly with the paint held upright and spin to full speed. You can stop every once in a while and reverse the drill and spin the other way. It only takes a few minutes of spinning to thoroughly mix your rattle can paint.

When through spinning pull the t-shirt and paint can out and it is ready to use. I keep the t-shirt section inside the pipe for next use.

This method mixes the paint thoroughly and saves my arm from the shaking.

So if you use rattle can paint for very little money you can get better mixing of your paint for a better result when painting your CNC projects.