@Griff If you could share that file for the Makita mount that would be great for me!

Here you go. I’m sure it could be improved upon. https://a360.co/2kcASGT

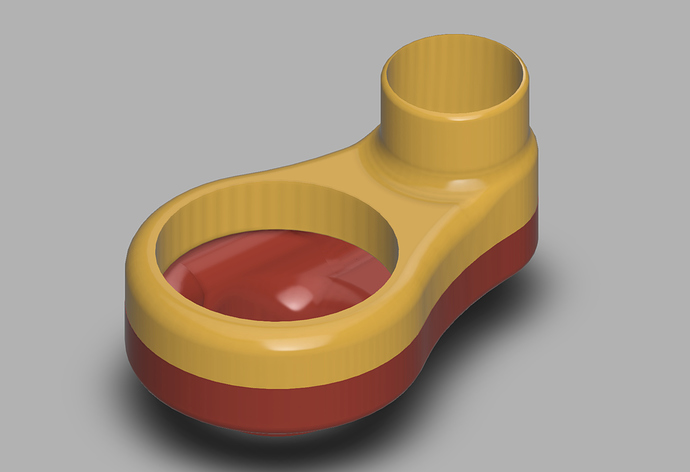

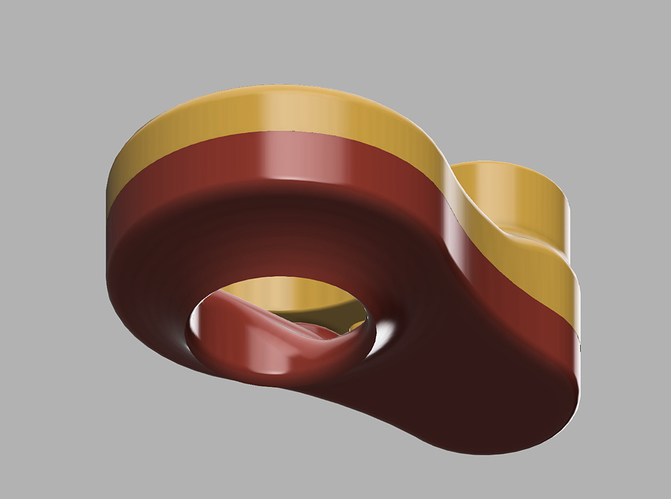

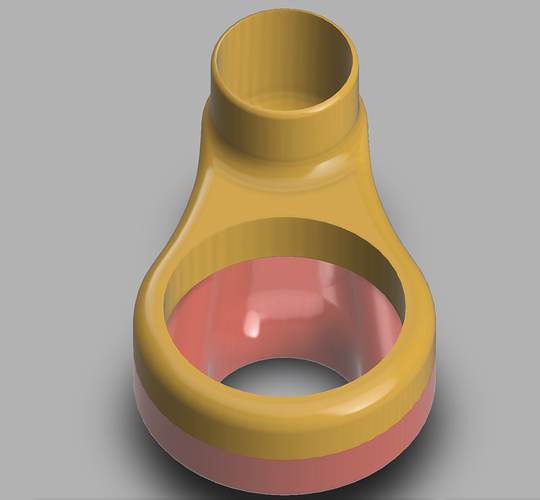

Here is a design i have been playing with

The plan is it’s bushless and clips together using my fav thing on earth - magnets

Now all I need to do is work out how to use my 3d printer… I’ve been sitting on it for about 2 months

That looks interesting. Friction fit I guess? Nicely organic.

@Griff Did I read you modified one for the DeWalt? Do you have that original file?

What printer do you have?

A flash forge creator pro early version.

My issue with it is the slicer, it’s not flexible enough to do anything. I’d love to use cura to see if this fixes my issues but the .x3g writer doesn’t do toffee and I can’t work out how to fix it.

@Griff this is just a ‘idea’ if it actually works I’d add a couple of screw holes to the top mount or tape or sumin…

Here you go: https://a360.co/2KGxGOW

I also printed my own boot, it had magnets holding the brush on. I also found that i was losing z steps during jobs due to the bristles fouling on the work, or the bristles would hit the job/clamps, pull them off and break the endmill/ruin the job…

I’ve now had the first iteration of suckit since they started making them and haven’t had one issue. 10/10 would recommend.

I have a Flashforge Dreamer - the software & slicer is absolute rubbish in my opinion. I paid for Simplify3D and it completely changed the game. Jobs are super easy to set up, and the results on the printer were 40-50% cleaner, and a lot faster… $150USD but worth every cent

I’ll second Simplify3D software, it’s awesome! A couple years ago my job tasked me with buying a large format 3D printer (1Mx1Mx1/2M build envelope). I found a machine and the seller recommended using S3D. I was already using it on my home machine and that was the final selling point. The guys in our prototype shop love it, simple and powerful. Great software!

Dan

I struggle enough with CNC’ing that I am nowhere ready for 3d printing lol! I stuck with the reality 3d printed boot so we’ll see how it works out. Appreciate all the feedback.

I went in reverse order. I went from manual machining (Bridgeport and lathe), to 3D printing, to ShapeOKO CNC. I think the learning curve is actually steeper to CNC than with 3D printing. In 3D printing you can make impossible shapes that you can’t machine, there’s no clamping, and generally one “bit” size. 3D printing is pretty easy actually, and the software is simpler.

Dan

What type of brush and where did you purchase it from?

McMaster-Carr

Here is the 1" -

7900T1 Easy-Cut Strip Brush 1/4" W X 3/16" H Backing, 1" Overall Height, 3 ft. Length

And here is the 2" -

7900T5 Easy-Cut Strip Brush 1/4" W X 3/16" H Backing, 2" Overall Height, 3 ft. Length

And the webpage -

I notice they have a non-static brush. I’ve never tried it, but I have has issues using my new O flute plastic bit when the brushes are touching he acrylic I am cutting. No issue when the bristles are not touching. So I assume a static issue. I have never had that issue using my regular old 1/8" 2 flute cheapo bit, and feel I get just as good results as the $25 plastic bit.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.