Oops, sent too quick, I did add a dust deputy, made a huge improvement in conjunction with my suckit…

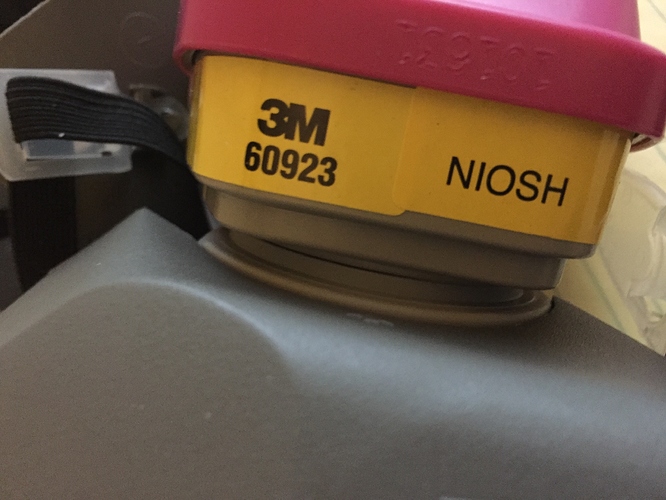

A dust separator, the Dust Deputy being a fine example, can reduce the particulates that get to the dust collector by 95%or more. It’s a necessity to avoid going through HEPA filters quickly. A HEPA filter is necessary when the exhaust air is dumped inside with humans.

My shopvac has what it claims has a HEP filter in it, but only seems to cost about $10 - $15,

The cost is a bit suspicious, HEPA filters are usually more expensive. One possibility is that they are small or lack the large capacity for particles that the more expensive types do.

it is an old ~20yrs shopvac so either I recall incorrectly, or they are no longer made,

The good ones last…

if you were to recommend a vac, what direction would you go.

That depends on several factors, including budget.

For my situation right now, it is only the shapeoko, but I can envision a more complete shop in the future …

If one is investing in the future and is thinking that they want excellent dust collection now and room for a larger machine one should purchase a formal, industrial dust collector. Surprisingly, they aren’t that expensive. This should be coupled with a formal, industrial dust separator.

When using this approach, one wants a dust collector that uses 4" or larger tubing and 1000 CFM or more of air flow. The dust separator should also use 4" or larger tubing. Then run the largest tubing you can for a short as possible. Only when necessary adapter it down. Under all circumstances the tubing should not be less than 2.5" when collecting to the dust head.

If you want to discuss the specifics of this approach, let me know. The budget is higher than a simple shopvac but this is a one time investment. The only throw away is the last section of tubing. Overkill for now but room for the future.

If you’re not shooting for that, then we’re into dust collectors and separators that should use a minimum of 2.5" tubing. We want a huge amount of air flow. if we can dump the exhaust air outside we don’t need a HEPA filter. Otherwise (air is dumped inside) we need a HEPA filter.

An excellent all-in-one choice is Festool. They are rated for Asbestos removal! They aren’t cheap but boy they work well. Bias statement - I use Festool for my small CNC work. Excellent choices are also offered by Dustless Tools, Rigid, Nikro, and Vacmaster… and there are others.

For larger machines, I use the larger approach. For those with a limited budget, hybrids can be designed.

A significant issue with dust collection is NOISE. A CNC machine in an enclosure is considerably quieter than the dust collector… which means we need to design an enclosure for the dust collector too!

Another significant issue is the quality of tubing. Conductive (“anti-static”) is called for, as is proper grounding. Thankfully, there are some good sources for this at relatively low cost.

mark