Any suggestions on reducing the time on the attached CC file without impacting quality?

For Jeff.c2d (960 KB)

What material are you using?

The Roadster has a lot of detail and depending on the material you have you may not want to push speeds too much faster. You could pop out some of the smaller sections or create fuzzy places and make more work.

On the Jeff’s Roadster tool path roughly 70% of your cutting time is using the Vee bit.

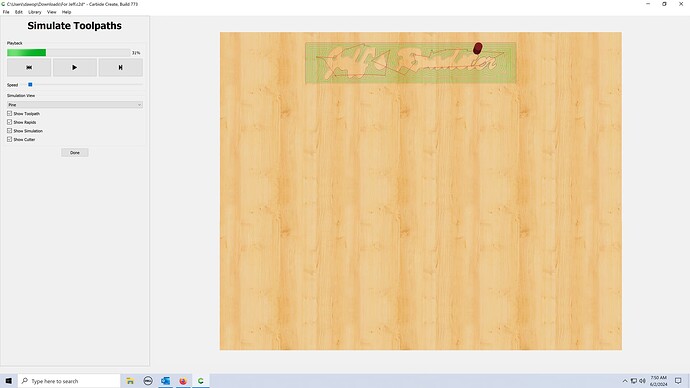

slow your simulation speed way down and you will see when the 1/8 bit stops cutting and the tool changes to the one in the image below. This is where the Vee bit is cutting ALL the areas that the 1/8 bit is not able to reach due to the diameter of the bit being too big to fit in the smaller areas.

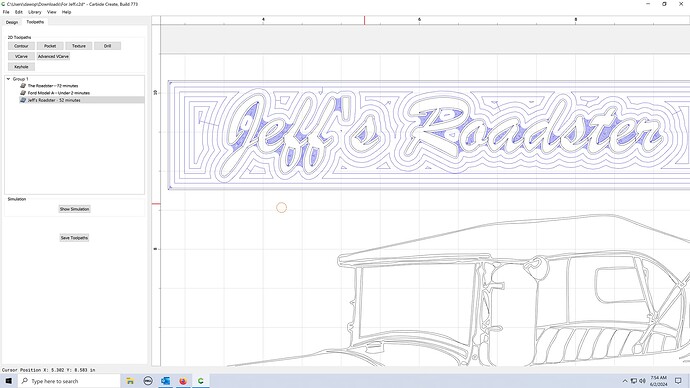

In this image below look at the dark blue areas that have tighter /more blue lines. this is the sections that the Vee bit is cutting.

Things you can do to reduce cutting time are.

-

Enlarge this section big enough to fit more of the 1/8 bit in these sections. You wont fit the bit in every area and will still have the Vee bit cutting these areas. If you look just below the word Jeff you will see an orange circle. this represents the diameter of 1/8 bit and you can move it around in the darker blue ares as you test different sizes of the text.

-

If resizing is not an option you could leave it as is and while you are cutting you can increase the feed speed by 10% or more. This option I use almost every time and it does reduce cutting times.

-

Really I would run it as is, your results this way may be the best for you and the detail you want. You could still use option 2 and reduce some cutting time.

Do some tests on the same material and try some of the suggestions…See what happens when you change things.

Hope this helps

Anthony

Feed rate on the 1/8" bit is way slow. You have it set to 10 IPM, the default from Carbide is 45 IPM, and that is considered “conservative, you can likely speed it up”. CC also has a low DOC for the 1/8", no reason you can’t go 0.051 at 45 IPM.

The 30 V Bit I run a lot faster - 0.04 @ 40 IPM. There’s an extra pass, but it’s still faster than 0.05 @25 IPM. I would experiment here, I don;t think 0.051 @ 40 IPM is out-of-reach.

Why 0.051? In general, having the DOC exactly divide the total depth can lead to rounding errors that end up making another pass that has essentially no effect. A DOC of 0.051 into a total depth of 0.15 ensures that you have only three passes, not four. The extra 0.001 on your DOC isn’t going to affect how the tool cuts. You could also set the total DOC to 0.149, that would have the same effect.

That reduces the time on the upper text by over half.

The model itself is way over-detailed for contour cutting. There are a lot of areas where you are basically cutting air because another feature nearby has already cut the area. Simplifying this would be a lot of work though, you may want to see if you can find a less detailed model.

Also, not related to speeds but, you may want to experiment with downcut endmills for the pocket clearing. They have much less tendency to tear out the details. For shallow pockets that have any kind of detail, I now always use downcuts.

Another thing to try is changing from Advanced VCarve to pocketing for the top text. The text doesn’t have very many sharp corners, so the rounding effect you get from using endmills isn’t very noticeable. About the only thing that would need to be changed is adding a little bit more space between the last two letters.

A 2mm bit pocket, followed by a 1mm bit contour, to 0.15 depth, takes only 35 minutes.

If you have CC Pro, you can use Rest Machining and a 1/8" bit to start, and it’s under 30 minutes.

Your original depth was 0.15, almost 4mm. That may be a lot deeper than you really need.

If you go 0.08 (approx 2mm), you can get that down to 18 minutes.

If you use downcut bits, you could paint the region before cutting, and you can get an effect like this:

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.