@Lookin4help in the fwiw category, here is the recipe I settled on.

Female/pocket:

start depth 0

flat depth .22"

Male/inlay:

start depth .16"

flat depth .27"

bits/feeds n speeds:

1/8" whiteside downcut stepover 0.06", depth 0.125", plunge 80, feed 160IPM, RPM 17,000

Amana V 30degree 0.01" tip, stepover 0.007", depth 0.2" (its a sturdy bit for lateral cutting even if the tip might be fragile  ), plunge 20IPM, federate 40IPM, RPM 20,000.

), plunge 20IPM, federate 40IPM, RPM 20,000.

I even though I am comfortable with 0.2" DoC, I run 2 advanced v cave paths for the male. The first pass with the start a 0" and flat depth at 0.16" to get the groove down to where the real V path thinks it starts. The second one set as above. Additionally, I run just the V bit path a final pass as I mentioned in the post above. I use a code splitter (GcodeSplit - Split gcode files by toolpath) to get just the V part to get rid of the fuzzies as a final pass. It takes a bit more time (since these are not fast runs on a complex carve) but way less than using an exacto blade and fine grit sanding wheel to get rid of the fuzz. In my head it saves time (I have not measure the difference so it may just be in my head) but it saves endless frustrating cleaning the inlay which is measurable in the amount of swearing.

As a side note, splitting the gcode also lets me run the V path first on the inlay. One of the videos I saw suggested this to prevent tear out of fine detail so it is more supported during the V. I don’t know if the 40IPM/20KRPM fixed it or doing the V first since I changed them both at the same time in an experiment. It worked so I stopped tinkering.

This gives a “glue gap” of .06" and .11" above the surface for bandsaw/margin. I have glue gaps in quotes because my experiments where I’ve cut a cross section has it at either unmeasurable or in the single digit thou with a feeler gauge. For cutting board, any large gap (like 60 thou!) would eventually trap moisture, encourage mold and bacteria, etc. I find good clamping pushes it closed both on the sides and the bottom. You can be less aggressive and have a bigger glue gap if your use is more tolerant of gaps under the inlay.

Also, I am going for a robust inlay since a cutting board will take abuse. No need to go .22" if it is decorative.

Sorry for the long post. Hopefully that helps you dial in what you are trying to do.

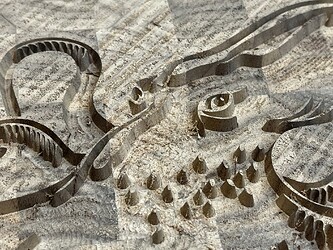

Fuzzy photos

Before

After an extra V pass

[edit to add 0’s dropped from rpm 1700->17,000 & 2000-> 20,000]