let’s say I am running a job where 1/4 way through I decide that I could be running it way faster and 200% isn’t fast enough. If I change the cut per tooth in 360 and re-generate then it will be faster but I have to start at the beginning again. Is it possible to skip code, are the values absolute or relative

I have not found a way to do so. Usually I just adjust my speed and then start it again at max speed just till it gets close then slow it back down might not be the right way but it’s the only way I’ve found that works for me

Gcode is just a text file. CC V7 generates a c2d file that the gcode is encrypted inside the c2d file. If you have the pro version you can save gcode. The other CAD programs generate gcode. If you are running the gcode in CM there is a running line number of the gcode file being run. Note that line number and edit the gcode in a text editor. Go to the line number where you stopped and back up until the last rapid move. Then copy from there to the end of the file and copy and paste it into another file. Then go to the original file and copy the preamble of the file and paste it into the new file. The gcode has 3 parts. The preamble, gcode commands, and post instructions. It is not easy but is possible. Technically the time it takes to do all that you could just start the file with the parameters changed you wanted and let it run.

I do not run 3rd party gcode senders but they may also keep track of the gcode line number it is executing.

A more important thing to consider is if you are generating a file that the parameters are so slow where are you getting the F&S data. The C3D CC uses conservative F&S but if you are needing to run more than 200% you need to look at the tool path generation in your CAD program and may be more productive than running at 200+ percent. Another factor to this is running your machine to its limit. Time is money but if you are breaking down your machine there is no money being made. So a balance must be made between making money and not making money with a broken machine. These things need to be considered more than what speed your are running at for a job. Good Luck.

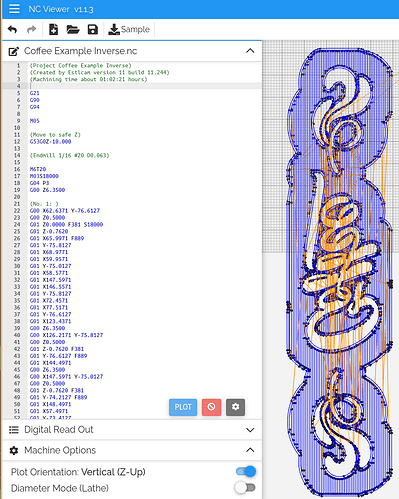

I use ncviewer.com to do this. You get a preview and can easily edit and replot. You need to know about where your tool path stopped. Here’s a quick example. This first image is the original file:

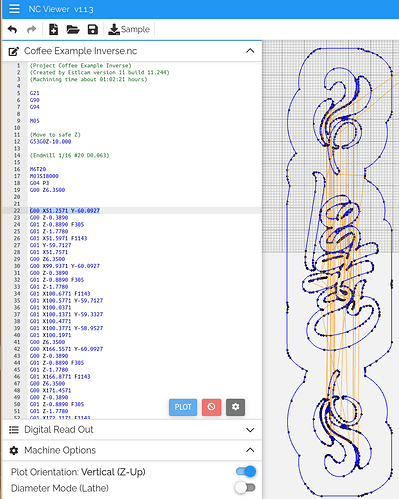

And this is one I edited.

In the edited version you can see I kept the tool change info that has the speed info. This is important if you are using the software to start your router/spindle. If you are manually starting, doesn’t really matter.

You can see I have line 22 highlighted. Line 19 puts the bit at your safe Z height and then line 22 is an X/Y movement. You don’t want to start on a Z plunge movement (line 23). Make sure your first movement is your safe Z and then your second movement is X/Y to the material location you’re starting at.

You can search in ncviewer for things like tool changes (M6T) which can help if you need to remove your first tool tool changes and start part way through your third tool change, or whatever.

The examples above I created in Estlcam, CC code will look a little different, but same concept.

This topic was automatically closed after 30 days. New replies are no longer allowed.