I just purchased a used Shapeoko Pro. I’ve big plans for it. I already have a new Masso G3 Touch, 4 12nm nema34 closed loop steppers with drivers, & a 3hp ER20 ATC water-cooled spindle with a Delta VFD.

I need to get the needed ball screws to replace the x & y axis belts. I’m also thinking of completely replacing the Z carriage with one with bigger ball screw & linear rails to accommodate the nema34 & achieve longer Z travel.

All thoughts, remarks, and suggestions are appreciated.

I have an S3 XXL with linear rails, ball screws, water cooled spindle (no ATC, yet) and a Masso controller, so that all sound good. The nema34’s may be a bit overkill.

I had the linear rails and ball screws and these motors, Amazon.com, running on the Carbide board before I got my control box done. Had to slow the feed rate down to 80 in/min, Painful to watch a rapid move from the front left to the right rear. After the controller was done and running the motors through a driver I was able to hit 180 in/min rapids. Not once have I bogged down the stepper motors. I’ve cut ¾” plywood at full depth with a 3/8” compression bit at 140ipm, soft and hard woods and plastics, aluminum (6061, 5052 and MIC6) and mild steel up to 0.125” with no missed steps.

I did order these 4-5 months ago, https://www.omc-stepperonline.com/ts-series-4-axis-3-0nm-424-83oz-in-nema-23-closed-loop-stepper-kit-w-power-supply-4-clts30a-v41, just haven’t gotten around to installing them. Maybe next month. Hopefully I’ll be able to hit 280-300ipm with these.

Whatever you decide I’d like to see what you do. Nema34’s are beasts. Good luck

I’d tend to agree on the NEMA34. If you’re sticking to sensible size ballscrews (20mm) then NEMA23 with a decent torque and, critically, a decently high voltage drive to maintain torque at speed should be more than enough. In a ballscrew application it’s not the machine loads you’re driving, it’s accellerating and decellerating the rotating mass. I’d also go with a closed loop stepper so you can at least get an alarm on missed steps and stop your job.

If you really want more motor, then I’d suggest going to one of the servo options rather than fighting with bigger steppers, the rate of development on servos is making steppers a niche legacy tech pretty quickly IMO.

I’m strongly thinking of making this machine able to cut steel. I think I’ll be using 25mm ball screws along with comparable linear rails. I already upgraded my Laguna iQ pro with AC Servos running on another Masso G3 Touch, and I already have the closed-loop Nema 34 steppers.

I , also, just ordered the new Masso Plasma DTHC Module & the Masso Multi-Head Support. I haven’t decided which machine I’ll be adding the Plasma Torch to it.

May I ask you to post some pictures of your upgrades?

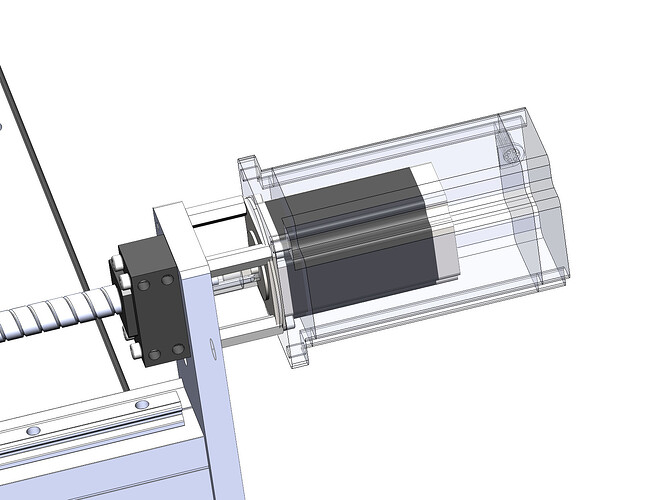

This is the Closed-Loop kit that I have.

These are the only pics I have on my phone of my machine. They were from back when I was puting it together. I’ll get some more tomorrow.

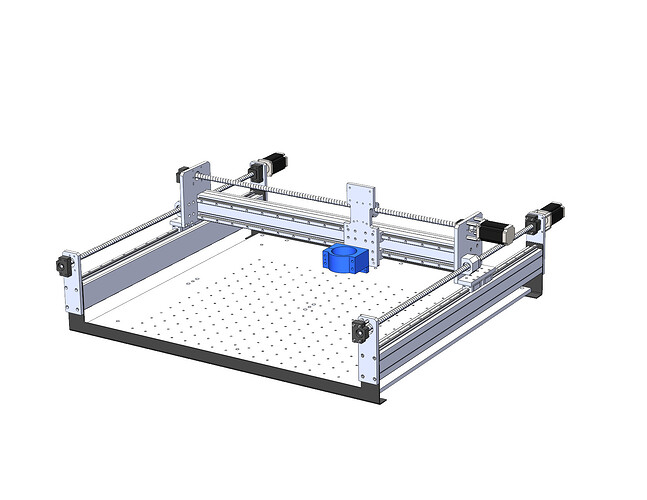

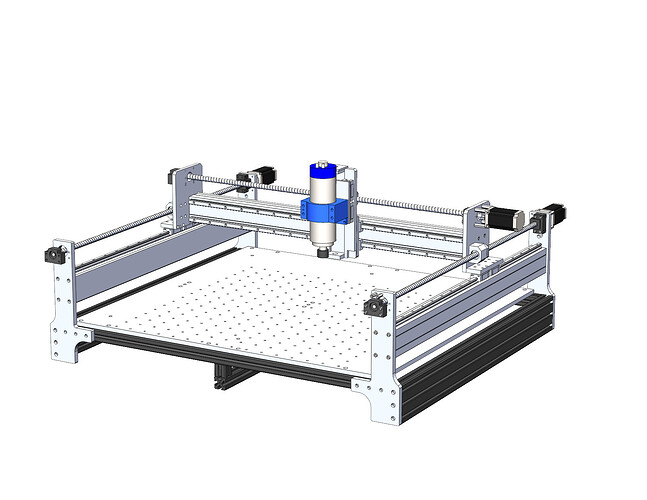

I modified what @DanStory did and upgraded it to ball screws.

After seeing what @CNCInspiration did with his machines I changed my design again.

I’ve got all the extrusions, new closed loop steppers, and the ATP5 plate for the end brackets. I just don’t have the time to do it.

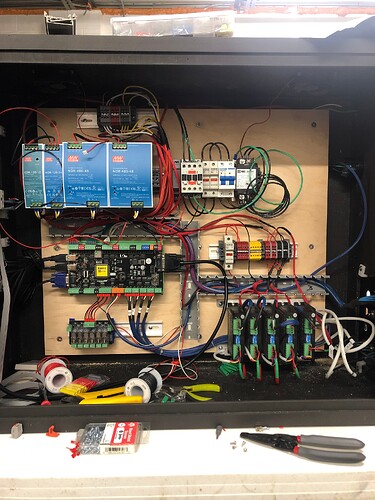

The control box that took me forever to build.

Just to compare a nema23 to a 34.

Not much different that the assembly picture. I’ll get around to the drag chains and cable management some day. But for now this works.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.