Does anyone know if the main retract height can be overridden in the gcode file? If so, where is the retract height located in the gcode file? I need retract height at .500mm and CC won’t let me enter the low number.

0.05 inch or 1.0mm is the minimum retract height allowed in CC.

Not really, the height is sprinkled through the G-code every time a retract happens. There’s no central location to change it.

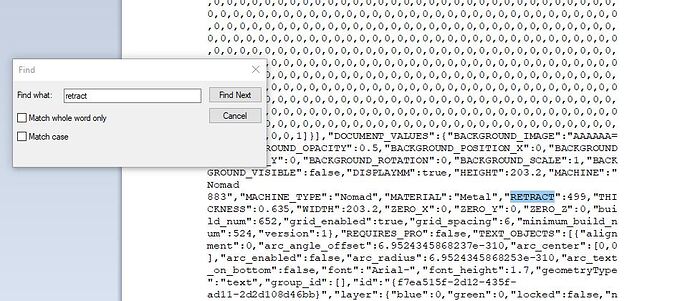

Sure. Set your retract height in CC to 499. Then edit the file and replace all “Z499.0” with “Z0.5”

That should change the value in Settings, but you’d still have to output the G-Code again to get the Z499 in the output file.

I changed the retract height in the c2d file first through wordpad. Then opened the c2d in CC, then created g-code file. Checked for all z’s and they all changed to my new height. Hopefully this is my new workaround. I’ll test cut later to see.

I gotta play devil’s advocate ![]() & ask, “Why is 1mm too much?”

& ask, “Why is 1mm too much?”

OK, back to “angel’s advocate” ![]() … No idea why they would limit the retract height to anything > 0.0 ?? And even 0.0 is not entirely ridiculous.

… No idea why they would limit the retract height to anything > 0.0 ?? And even 0.0 is not entirely ridiculous.

Like other UI decisions, this comes down to tech support interactions.

We keep telling folks not to start off w/ expensive/irreplaceable/sentimentally valuable stock for a first run of G-code, but we keep getting e-mails where folks are … well … you can fill in the rest.

I do a lot of tedius small engraving and believe it or not the amount of time it takes to keep retracting just 1mm adds up. I’m working on a small section of metal and don’t need hardly any retraction so time is of the essence in my work.

What is your Depth per Pass?

Could you manipulate your first few Toolpaths so as to allow you to set origin 0.5mm lower than the top of the stock?

Very small bit with diameter of .0177. The setting below is what I finally landed on the keep from breaking the bit. Also, my max cutting depth is .01. Cutting brass, copper and nickel silver and sterling silver. I also us VCarve but it takes longer than just doing a contour of each letter. Letter size is roughly .08 w x .11 h. I often times have to get in very tiny spots too. Any suggestions are appreciated.

DPP =.001

Feedrate=2.2

Plungerate-.162

RPM=1275

Fair enough.

The defaults are already greater than those, yes? I could understand a warning message, but not a hard limit.

I assume these are English units. (asking because you seemed to be programming in metric)

Did you leave a digit off the RPM? Do any routers go that slow?

These are English units and programming in inches and the RPM is 1275, no missing digits. This is on the Nomad 883. My bits are very small.

edit the file with note pad ++ use the find and replace function it will replace all the z heights that should do it for you

edit the file with notepad ++ use the find and replace function it will replace all the z heights that should do it for you

This topic was automatically closed after 30 days. New replies are no longer allowed.