Is there a way to tell the program to return to the start point after a bit change? I’ve had a few issues where it crashes into a clamp on the way over to cut. Those issues would not exist if it just went back to the starting point first.

Not conveniently.

You could put a very shallow drill toolpath at the origin after each tool change.

Easier to increase the safety/retract height.

Ok that’s what I figured (retract height).

I snapped off my 1/8 round finishing bit a few days ago so that was not fun.

You tagged this as Vectric. Did you mean to do that? I started using it recently and I think with the Shapeoko post processor mine is returning to start after a bit change.

I will double check next time I am at the machine.

Yup I only use Vectric.

There are several ways to secure your work on t he spoilboard. The easiest and fastest way is painters tape and super glue. With that method you do not have to worry about hitting clamps. The next method is to make cam clamps that do not stick up very high and hold your project securely. Along with cam clamps I use a long L bracket to secure the project initially parallel to the X axis. Another method is the various clamps C3D provide like the gator tooth, tiger claw, essential clamps, and crushit pro clamps. All of t he C3D clamps are relatively low profile.

If you are using the clamps like these quit that and get some lower profile clamps.

These type of clamps are useful in other areas of a shop but not so much for a CNC.

I seem to remember that Vetric had some strategy for avoiding clamps. It may be in Aspire but I thought they had a way to place your clamps so you could avoid them.

Here is a link to a vetric article about clamp avoidance. Looks like there is no software solution even in the high end Aspire software.

I use a combination of most clamps and hate them all. I was using the ones in your pic when i crashed into it. They are quick and easy but i’ve ran into them several times.

I just need to take the time to use tape/glue i guess, never had any issues with that, just takes longer to get setup.

I also need to get some decent cam clamps made, that’s been on my list for ahile, but i never have time to do that kind of stuff, i’m too busy completing customer orders usually.

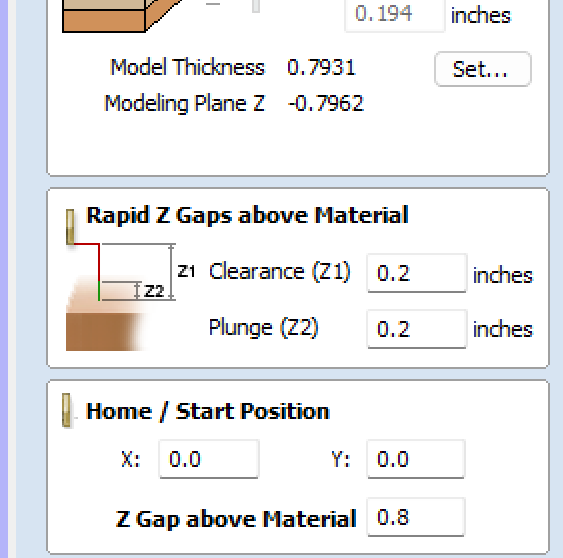

Are you saying that you use Vtransfer from Vectric to run your machine? I have limited experience with it but I don’t think you can do much more than change your Rapid Z gaps above material.

Didn’t notice this was in the Vectric area.

Isn’t there an option for a “Datum” which as I understand it is a point to which the machine moves to in certain circumstances when rapiding?

I use Vcarve Pro, export gcode and use carbide motion to control machine.

The home/start just is the initial program start, if you do a bit change it doesn’t return to home it just runs to start that cut, which means shortest path possible from the bitzero to wherever that cut starts.