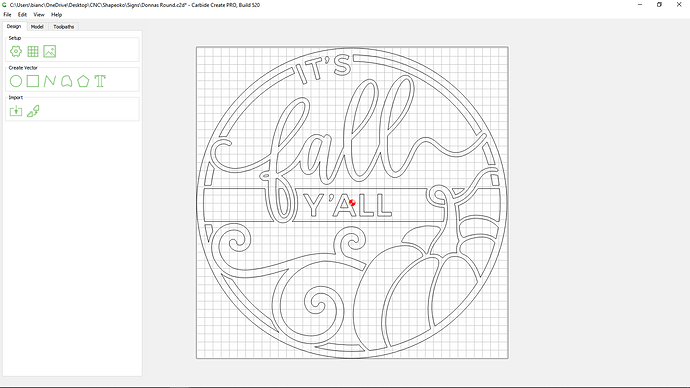

I am trying to make a sign where the letters and art work sit on top of the background.I can’t figure out how to make this happen. If I do a pocket tool path it wants to carve the letter and leave the rest. Any help?

What are you selecting for the toolpath?

Could you post the file?

Sure, here is the file. No matter what is selected it always wants to do the inside of the letters, boarders, whatever is selected.

Donnas Round.c2d (294.5 KB)

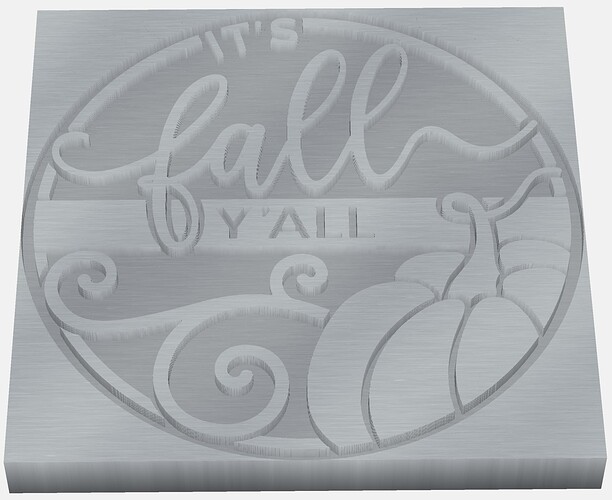

Select the entire group, then pocket. (Although you may want to tweak this for roughing out with a coarser bit first.)

Carbide Create uses the odd/even rule for deciding what to cut, and it helps to at least understand that a bit.

The way this works is that if you start all the way at the left (It works also up /down or from any other direction) and go to the right, every time you cross a selected line, you add one to the count.

The count starts at zero (I’ll declare that an even number even though some math folks might object) which is even, so the area does not get cut. Once it crosses the first line, the count becomes 1, which is an odd number, so that area will get cut out. The next line it crosses, makes the count 2, which is even, so that area won’t be cut, etc etc… odd = cut out, even = not cut out.

So for any of this, the trick will be to either select, or sometime even add, lines in your design such that the right areas have that odd count to get cut out.

Thanks for the help all. This is perfect. Another question. The way I will carve this is to run a contour with a 1/16" bit to get the detail then run a 1/8" (or 1/4" depending on detail level) for the rest. Should I reverse that order? This particular carve is in pine. I have a #251 (0.25" Downcut Flat Endmill) or 1/16 compression bit. Should I be using one or both of those?

Ed

it’s usually better to run the bigger bits first and follow with the smaller bits…

also if you go in steps of “half or more” you won’t leave any residue, so from 1/4 to 1/8 and then 1/16 works, but if you go straight from 1/4 to 1/16you may leave some things.

(only the first would be a pocket potentially)

on pine, definitely go downcut. Compression is more tricky to get right. The downside of downcut is that you might get some fuzzy edges at the bottom of the wood, but in your design, that’s the easiest part to sand clean… the top is not. I’d opt for optimizing for a clean/nice top…

Hmmm. I don’t find sanding recesses easier than running a flat sanding block across the top. Perhaps because most of my work is small and generally in hardwoods with small bits, I find a few passes with 320 grit across the top cleans up the “fuzzys” easily. If the wood is coarser and the bits larger, I’d just cut deeper to allow for more to be taken off the top.

I meant if you cut all the way through, that’s where you might get fuzzies. Pockets from the top don’t have this. …

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.