What’s the upgrade???

The upgrade is a replacement impeller that has a different shape. It increases the CFM’s of the original unit. In a woodshop where you are using it on larger pieces of equipment such as a planer or jointer or multiple tools being used simultaneously it can make sense.

Bill

A larger impeller with backwards vanes apparently doubles the working cfm.

Thanks I’ll order one

I think they are out of stock unfortunately. I did read that they take advanced orders.

Max,

Keep in mind the HF 2HP dust collector is a different machine than a shop vac. You can only pull so many CFM thru that small hose. It has less static pressure than a shop vac. There is alot of info on dust collection, duct size, airflow, et available to research. Bill Pentz’s website is a very good resource.

For filters, consider Wynn Environmental. They offer very good MERV15 filter kits.

You may want to consider a larger pickup tube from the dust shoe for more airflow. We are presently running two SO3’s thru a Dust Deputy XL with the 1HP HF dust collector and a Wynn Environmental filter using ROGDC dust shoes. The ambient noise from the dust collector is much more quiet than the two Festool Dust Extractors we were running and has much less of a heat load.

Finally something I can comment on intelligently here…

Between my Shapeoko and my Drum Sander my HF dust collector has plenty of power to manage the dust output I generate because I have taken the time and spent the money to set it up correctly but out of the box it was downright dangerous… If I were to do it over, I’d really strongly be looking at a Laguna HEPA unit but those are $$$… Something to really consider is that the dust from Sanders and Routers is very bad news, you cant see the stuff that actually hurts you, you just feel it a few hours later after the damage is done… The dust you can actually see is just the canary in the coal mine saying GET OUT. The bags that come stock on most dust collectors just pass the fine particles right through making them very effective dust pumps, quickly fogging the room with the superfine dust from the moment you turn them on. The TLDR; is if you are going the HF route, buy a Wynn Environmental Canister Filter and make/buy some sort of separator like a Thien Baffle or Cyclone to reduce the fines that actually make it to the filter (or you will be constantly cleaning the filter which is a royal PITA). I’d also strongly consider the Rikon Impeller, (Just call them and get on the list, mine took 60 days from order to delivery and they sell these by the truckload to HF users I’d expect it to take longer in the days of the Coronavirus…) if you are not going to put the collector right next to the machine IF your electrical system can handle it… for the run to the Shapeoko use 4" hose for as much of the run as possible and use as little 2.5" hose as possible going to the dust boot, don’t even try to use 1.5" hose…

I have done a bunch of testing with what I own, a decent anemometer, a Dylos particle counter (I have allergies and asthma so its a purchase that made sense to me) a couple shop vacs, a Festool CT36 and an upgraded HF dust collector… I’m not digging out my old spreadsheet I used for all my testing/notes but I’ll say that you can definitely make a HF collector work well for a small shop and have it do a good job keeping the air in your shop safe to breathe its just going to cost a lot more than $200… The Festool is fantastic but expensive (to buy and own, the bags are expensive too) and a shop vac is adequate if you can use it in a space where fine dust doesn’t matter (garage) and you can wear a respirator… if you can afford a particle counter get one! I have had a two instances where something didn’t seal right and my dust collector was pumping dust out into the air unfiltered and the Dylos alerted me to what was going on within seconds…

Here is a quick breakdown:

Dust Collector - LPHV - Low Pressure, High Volume - They move a ton of material but compared to their volume they don’t output much static pressure, they really don’t do well when constricted (eg long 2.5" runs) which is why people running a dust collector use PVC piping for the majority of their runs and use the shortest amount of flex hose possible. They are also not really capable of picking heavy objects up off the floor, eg, nuts and bolts. Don’t be mistaken that low pressure means no pressure… A Dust Collector is more than capable of collapsing thin walled steel duct pipe or in some cases even steel drums! Dust Collectors like the HF unit are plenty adequate for a small shop but thing of it along the lines of buying an engine for a car you have to build, sure its $200 now but by they time you add a Wynn Filter ($200) a Super Dust Deputy ($200), Rikon Impeller ($120 shipped) and all the stuff you need to make it work: Blast Gates $15-20/ea, flex hose $50-100, DWV pipe/fittings (~$100) the costs really start to add up. My HF collector (Wynn + Super Dust Deputy + Rikon Impeller) can easily clean the air in my two car garage shop in about 30 minutes if I open up all the blast gates

Shop Vac - Rigid, Craftsman, ShopVac - HPLV - High Pressure, Low Volume, They can pretty easily pick a nail up off the floor but are LOUD and generally don’t do a great job of filtering the air which is why they sell HEPA filters as upgrades, but even with these filters they aren’t HEPA rated. These are great budget hold me overs but please for your own sake wear a respirator when using them. Definitely invest in a Dust Deputy of make a mini Thien Baffle for a 5 Gallon Bucket, once a Shop Vac’s filter is clogged the performance starts to dramatically drop off. Figure all in you are looking at something like $300 with the hoses you want (Bosch makes a really great shop vac hose that is available on Amazon for those looking) Shop Vacs have their place, its just for cleaning up saw dust and nails, not for collecting fine dust…

Dust Extractor - Festool, Fein, Bosch - Souped up Shop Vacs, that are MUCH quieter and specifically designed to handle fine dust from things like routers and sanders and track saws. They are usually HEPA rated and have adjustable suction but the filters are expensive, while you can use an extractor like a shop vac you’ll quickly find out that the bags are expensive as well. a properly set up dust extractor will keep the air relatively safe to breathe. I love my Festool CT36 and if it died tomorrow I wouldn’t hesitate to buy another one, they really are fantastic tools I use it for my tools that I cant hook up to my Dust Collection System like my Miter Saw, Track Saw, Domino and Sanders…

A very good write up by Dustin if you are looking at the HF option.

In addition to the Thein baffle and Wynn Environmental filter pay attention to your ducting length and any corners. NO 90° turns as air does not make right turns. It is all about air flow. If you restrict the air flow no increase in impeller size will help.

The photos are of a system I designed and installed at a retirement community woodshop where my wife & I volunteer. The fiber drum has a Thein baffle and you can clearly see the Wynn Enviromental filter. I kept the ducting to a single straight run which not only keeps the air flowing but also makes clean out of the ducting easy if it does becomes clogged. Notice all the blast gates come off of 45° adapters into the 4" ducting. Again to keep the air moving smoothly.

This system easily handles a tablesaw, planer, jointer & bandsaw. One at a time.

Bill

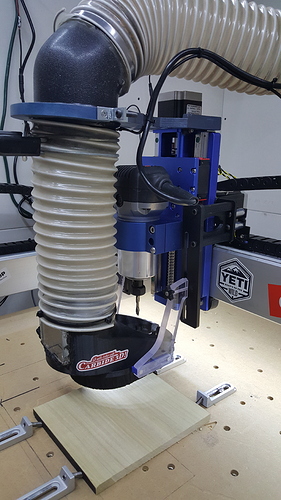

To add to what Craig, Dustin, Bill and others have said: restricting to flow on a dust collector is no good. I wouldn’t run a DC without a 4" compatible dust boot as you will lose all benefit to using it over a vacuum or dust extractor. I was able to get a 4" suck-it compatible boot printed (thanks to @MadHatter for posting his awesome design!) for my CNC and I would gladly put it up against any vacuum or dust extractor now that the airflow is right. I used to run a rigid vacuum to a 2" opening dust boot and I found myself cleaning up a lot more fine dust on the machine because if it made it past the brushes on the dust boot there was not enough airflow or suction to pull it back in. That is no longer an issue and I rarely ever have to clean off my machine now.

Edit: there are more pics in my gallery post

That is a great setup! I need to get a 3d printer, I keep saying this almost every day lol. I just cant figure out which one to go for, I keep coming back to the Dremel 3D45 but it is so old!

I ordered a 4 inch hose and 4 inch Dust Deputy, I will keep the HF and try to find an appropriate use for it.

I am going to recommend a Prusa i3 Mk3s. I’ve owned 4 Prusa printers (MkII, MkIIs, Mk3 and Mk3s) and still own the two Mk3 printers.

The hardware and software is continuously being updated and improved.

On a side note. I found you can download a decibel meter on your smartphone free. I tried a half dozen and found Sound Meter works the best. My router runs at 64db and the shop vac is 67db. Have tried it in a restaurant with high ceilings and I can get 84db.

Interesting! I’ve had Decibel X for iPhone installed for quite some time now, but curious about Sound Meter. So I have both installed on the same phone and tried them both sitting here reading the forum and they show very different readings.

Decibel X: 52.7 average

Sound Meter: 68.8 average

That’s a substantial difference! I’ll try them both again later this afternoon with the router and vacuum system running and will report that result. Sadly, I don’t have a real DB meter to compare them with.

Awesome I never thought to look for one, thank you for the tip Norm!

@MadHatter They want 5+ weeks for delivery though! That’s a long wait! Does a 3D printer fume out the house? The Dremel has a fan with carbon filter and enclosure. WIFI, ethernet and a camera, does down to 50 Micron and fast delivery with USA distributors. 2x the price though…

You don’t get any bad smells unless you are printing ABS or ASA filament. With PLA you can get a kind of sweet smell occasionally, but nothing bad. PETG doesn’t have any smell I have noticed.

Any idea what amperage that 2hp HF unit pulls?

Jimmy:

The Harbor Freight units are actually 1.5 HP The 2 HP claim is just marketing hype. We know this because they run on 110 volts and any 2 HP unit will require 220 volts.

This does not prevent them working quite well if used with appropriate separators, ducting and upgraded filters as stated by others. I have one and I can verify they work with a 20 Amp circuit.

Bill

I think the claimed 14amp could only be the max “spike” when turning it on. It doesn’t pull near that much amperage considering I can run it and a router cutting at max speed or my overhead air filtration at the same time off the same outlet on a 20 amp breaker. And I have read of people running one with no issues on a 15amp breaker.

I have an older 6HP 220CFM Ridgid shop vac, I think. Those numbers may be slightly off. It was the biggest monster they sold 6 years ago though. It came with a little muffler attachment and I added a Dust Deputy between the vac and my Sockit Dust Boot. I recently sold my house and had to put my CNC in storage until I get moved, but when I emptied the 5 gallon bucket the Dust Deputy was on the thing was nearly full of super fine dust. It does a great job.

Oh, and when I run the Ridgid vac and the CNC (with Carbide router) it hovers in the 90dB range. I have an app on my iPhone called NIOSH SLM. I heard it’s pretty accurate.

Finally have some data on the two app I had mentioned above, for what it’s worth.

In a quiet room, no PC, refrigerator or any other man made noise other than my breathing:

Decibel X: 52.7 average

Sound Meter: 68.8

With the router and vacuum running and 24" away from both:

Decibel X: 83 average

Sound Meter: 90 average

Actually cutting material, hard wood, at 24"

Decibel X: 91 average

Sound meter: 91.3 average

So at least they are close when it gets loud!