Hi,

Had a 6+ year old large Craftsman shop vac die on me, It was time to replace it. I bought a Harbor Freight dust collector with the 4 inch hose. It was very disappointing for me, about half the suction of a regular shop vac. Add said 1550 CFM, it seems more like 50. I suppose it would be due to restricted airflow bringing it from a 4" hose down to a 1.25 Suckit dust boot. Seems very powerful until you hook it up to a vacuum hose lol.

I have been waiting on the new inexpensive Festool vac for a month now, they are very slow to ship but I read it is only rated at 120 CFM. I can’t just sit around forever with no vac!

So I am returning the Harbor Freight dust collector and just replaced it with a Rigid 6.5 HP 200 CFM stainless barrel shop vac with Fine Dust filter.

I am very impressed with the Rigid so far, the suction is way way more powerful then my old failed large craftsman and is easily 4x stronger suction then the HF. I also read it has a lifetime warranty. I think I will stick with these Rigid’s matched with Dust Deputy’s for my Shapeoko’s and keep the weaker Festool for a cleanup unit if it ever arrives hah.

What’s the decibel rating on the Rigid, if you happen to know? I’m just about ready to replace the unit I currently have as it’s about done, but like you getting the Festool, I’m after something quieter if possible.

I am sorry I have no way to check that. It is moderately loud, but quieter then my old Craftsman. I saw they sell a Muffler/Diffuser for it, I was going to order it. If you are going for quiet, I tried this Dewalt shop vac, it is pretty decent but not much quieter then the Rigid. I used it for a cleanup vac for about 4 months. It is now whistling, and I do not know how much longer it will last. It is nice but not as powerful as the Rigid and only slightly quieter.

Shop vacs are ok if you are making short run projects. I just finished 3 different 12 hour plus jobs and ran my Jet DC1100 dust collector. I kept checking the motor to see if it was getting hot. The TEFC (Totally Enclosed Fan Cooled) motor was cool as it could be. There is a tremendous fan with lots of air flow running over the cast iron motor housing.

The subject of dust collection comes up from time to time. I have a Craftsman Shop Vac but also have the dedicated Jet DC1100. If you are going to be serious about collecting dust upgrade to a cyclonic type dust collector. I have a 4 inch Super Dust Deputy in front of my DC and get no dust in the bag and canister filter. On the 3 twelve hour jobs there was no dust on my spoil board on the Shapeoko.

Airborne fine dust is very bad for you and if you exotics can be life threatening to your or your family when you go inside the house. Be sure whether you use a shop vac or larger DC that you dust your self off before going inside. I use a leaf blower outside when I get dusty from using my table saw. The table saw ejects dust from the blade and all dust is not sucked up inside the DC. Several folks on the forum have had reactions to the dust in their shop so be careful.

Yes thank you very much for the warning. Currently I have a full enclosure with a Dust Deputy and a fine particle filter on my vac. I also alternate with my shop vac either outside daytime, or in a closed closet at night, and the closet has no dust residue after months so I am fairly confident it is doing the job well with the fine particle filter combined with the Dust Deputy.

The Jet looks like a very heavy duty machine. What is your dust shoe? What is the port size? Have you reduced the 4" hose down to 2.25 before and was it very weak suction?

The Jet says. 1100 CFM, the HF says 1550 CFM but my 200 CFM shop vac is crushing it with a 2.5" hose.

I have a Tite-CNC from etsy.com on my Dewalt 611 router. This is the second one I have had from the same vendor. The first one had a 1.25" hose fitting. I used my lathe to turn an adapter from the 1.25 to 2.5". The small opening and high cfm caused the brushes to be sucked up inside the vacuum hole. The first one had a spongy skirt and did not hold up. Later I replaced it with a Suckit Clone and did not like it. The arms to allow access to change the bit was constantly in the way and adjusting it up and down to get my wrench inside was a pain. I bought a newer version from Etsy the same Tite-CNC with a 2.5 inch port. It came with a brush attachment with 4 magnets and also a enclosed bottom that has a cone over the router bit. I dont use that one very much. The brush bristles were about 3 inches long and I could see it dragging around on the project surface. I used a pair of scissors and cut the brush down to about 1.5 inches. Because of my high cfm I get extremely good dust extraction.

Many people like the Suckit design but I did not like it. I do not know if the Tite-CNC makes one for the makita or the carbide3d router.

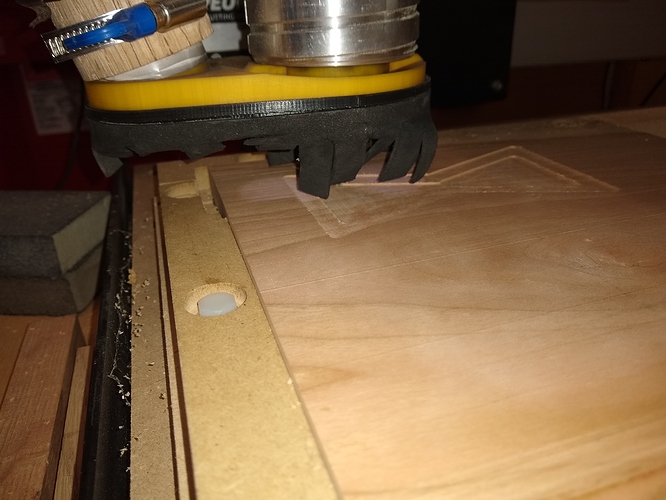

This is the original Tite-CNC Dust Boot

I am very pleased with this dust boot. The brush is easy to remove during bit changes and even without the brush attached the dust is extracted very well.

I have quit buying anything from Harbor Freight. Anything from HF is the bare minimum to qualify for what it advertised to do. There are several videos of changing the fan to a different one on youtube but save your money and do not buy the HF junk. There are some brand named items in HF that I buy but their brands are all junk and do not stand the test of time.

This is the newer version with 2.5" dust port on my original Z belt axis. I have since upgraded to the HDZ. You can see the brush (upside down) and the cone shaped attachment. Both attach with 4 magnets and is very secure but easy to remove.

That looks like a ton more airflow then the Suckit. Yeah I am wary of HF but the reviews all said it was a decent unit. It looks very solid to me, but weak. I will look for fan upgrade videos. Thank you very much for the information and congratulations on a very nice well thought out setup!

Vacs and dust collectors are different animals. Vacs will suck with a high static pressure, dust collectors are not as good at high static pressure. Dust collectors move much more air and rely upon larger hoses. If you use a small hose, it chokes the dust collector and it is not effective.

I have had the HF 2HP dust collector in my shop for years. The first thing I did was to replace the bags with Grizzly bags that stop much finer particles than the stock HF bags. I’d recommend that change to anybody that has one.

The only other thing I did was replace the switch on it after it failed. It’s really cheap and the internal arcing when you turn the unit on/off eventually did the original switch in. I did add a remote to it so I can turn it on/off while working anywhere in the shop.

To reiterate what Sheldon said, dust collectors (DC) have higher volumetric flow rates (CFM) where shop vacs operate with higher static pressure and typically lower volumetric flow rates due to smaller hoses and impellers. If you wanted to pick up a loose nut off your floor it would require more static pressure; but if you were trying to capture dust you would want to capture more air because the dust is much more dispersed over a large area. These two characteristics aren’t mutually exclusive but to get higher static pressure with higher volumetric flow rates you begin to go down the rabbit hole of system design: allocated space, piping sizing, impeller sizing, motor sizing = $$.

This may be a terrible analogy, but thinking of a shop vac with it’s higher static pressure in terms of catch… imagine trying to catch a baseball then imagine being in one of those cash grab booths with dollars flying all over the place. In one scenario, a good concentrated effort with the strength to handle the mass of the baseball would suffice; and in the other scenario, strength doesn’t really play a role and one concentrated effort may net you a dollar bill.

I believe the Ridgid shop vacs decibel rating is in the low 80’s. I have one in in my woodshop.

For my Shapeoko I use the VacMaster VWM510 with a Dust Deputy. The decibel rating on the VacMaster is 72 which is one of the reasons I purchased this unit. It has lived up to that claim. In addition it comes with a 15’ hose and a second 10’ hose. Both very flexible. It also includes a built in remote.

Bill

The VacMaster looks like an interesting option for the limited space I have available, thanks for the suggestion Bill.

The VacMaster seems to be listed at 75CFM. Is that enough for a dust boot?

I have a muffler/difuser on my Craftsman and Shop vac vacuum’s and I cant tell the difference with or without, waste of money in my opinion

I am a hobbyist and don’t put the HF collector on my Shapeoko but in general shop use for my table saw and especially my Dewalt 735 Planer it is fantastic. I do have a garbage can separator on it so not much stuff goes into the HF bag. Works great.

Tex:

Just getting started with a CNC so I will answer your question based on my experience in a woodshop with a hand held router. In that configuration which is not that much different than a CNC, and possibly more demanding, because we use larger bits and generate more dust the VacMaster would work well.

The most important thing about using a shop vacuum is to keep the dust out of the filter. The way to do that is by having a separator (Dust Deputy or Thien baffle for example) between the vacuum and the router.

If you choose to use a Dust Deputy I would strongly recommend getting a Gamma Seal Lid for the bucket as it makes emptying it out much easier. Gamma Seal Lids replace the snap on lids with a threaded lid.

The photo is my setup. Using this with MDF and a ‘Sweepy’ dust boot does an excellent job.

Bill

So I guess a question I have is, will a RIGID shop vac hold up to the 8-12 hr cuts? This is the issue I have with my RIGID now. I have it on a iVAC switch that kicks on the vacuum when the spindle comes on. After about 4-5 months the cord from the RIGID melted itself into the iVAC switch. I was actually looking at the $200 HF DC as an option. Suction is not the problem with the RIGID, it’s noise and how long some of the 3D cuts are.

Most shop vacuums are designed for 50% duty cycles. Not for continuous use. There are exceptions. My little Fein Turbo I that usually is in my woodshop ran (almost continuously) during our floods last spring for 48 hours as it kept the water seeping into our basement at bay. I was turning it off for a few minutes every 45 minutes to dump out the water.

Fein and Festool are probably in this league but correspondingly expensive.

I have a question into VacMaster support about the duty cycle on their products.

Bill

I have run my rigid shop vac for 6 hrs at a clip. Have had it now for 10 years. Kinda wish it would give up the ghost and get a new one.

This is the HF upgrade impeller (Part # 22), it is out of stock.