Alright… I’ve done a few test pieces. After the last one, my x axis has lost its location on the minus side. I’ve re initialized it, re zeroed at the northeast corner and it’s still stopping well short. It’s almost like it’s still zeroed on the job. Any suggestions? Would an x belt slip cause that? If that’s the case, why wouldn’t it correct itself after zeroing at the northeast corner?

After the machine initializes, and you set the zero position on your project, are you clicking on Set Zero, Zero All. Also, on your job, where is your Toolpath Zero set to. Center, Lower Left etc. When you set the zero position it should be set to that position

Here’s the procedure

Initialize Machine.

Jog the machine to the Toolpath Zero setup in your project. Center, Lower Left, Center Left, Top Left etc

In CM click on Set Zero, Zero All

Load and run your job.

When your job starts to run it should first move to that position

I can’t even get it to the new project because my x is losing memory. Once I initialize it, it checks the bit after home, slides over to the center of the table. I do a rapid position change to southwest and it stops about 10 inches from the x minus stop. Then I hit one of the rapid position changes to any of the center locations and it’s not on center after I do that but it centers itself perfectly after it reads the depth on the bit. It’s like my x has shifted off the table.

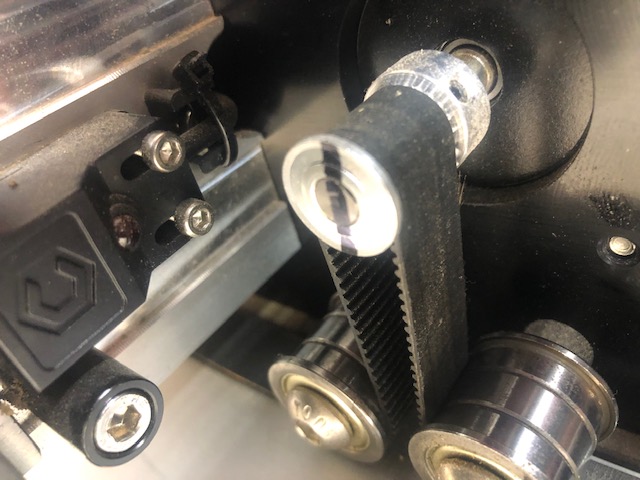

Ummm got it… a set screw has fallen out and it was stopping my x axis. I’m sorry for the inconvenience… any idea where it came from? It’s tiny.

First place I would look for where it goes, is the motor pulleys. Prolly wouldn’t hurt to check the rest of them also.

Stepper motor pulley set screw. Thank you!

A little blob of thread locker goes a long way with pulley set screws, also make sure they’re locking on the shaft flats.

Placing a line with a sharpie on the stepper motor pulley through the shaft is a good visualization for you to check periodically or if anything happens.

Check you mechanical issues first. Then send your config. Be sure to pick correct model and Z. The config is mostly configuring CM. CM controls how far your machine can move. If cm is not configured correctly the default config likely not match what you actually have.

Outstanding idea! I greatly appreciate your help, sir!

This topic was automatically closed after 30 days. New replies are no longer allowed.