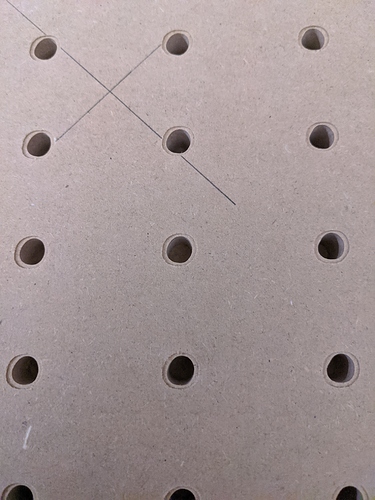

Tried making a secondary waste board with threaded inserts as my first project and the holes did not come out round. Thoughts?

if you try to wiggle with your hand (with the machine on, but the router off (!!)) the bit, is there any play in it?

@fenrus is right on, but once you see it wiggle, then what?

- Likely both X and Y belts or pulleys are loose (be sure the set screws are in place and against the flat on the shafts). The belts may not be tight enough (see the other guides here about this)

- If that doesn’t help, and you can’t feel anything move, your belt tension on X vs Y is WAY off, and you need to do some calibration, that’s a bigger task, but there are good guides here in the forum for it.

So I know I made sure to tighten my escentric nuts before I put my Shapeoko in it’s enclosure, but four of them were loose for some reason. Going to run another test in the morning.

Oh and my belts were loose. Like I said all this was tightened before putting it in my enclosure.

I put a little blob of the loctite blue threadlock on each of my Y axis plate eccentric nuts as I’d had them work loose several times, not on the bolt thread but a tiny bit on the face of the eccentric nut where it touches the steel plate, now they tend to stay where I put them.

Moving things around tends to loosen things up, not a big deal. They’ll loosen over time (belts stretch), or need a little adjustment (wheels wear/deform needing a little eccentric adjustment), so it’s good practice anyway.

Good Morning All,

This happened to me also. My issue was that the z axis was traveling too far down and the bottom wheels was coming off the the rails. I had to extend the endmill further out the collet. Just my two cents.

Jlap

Yep, I had lots of trouble with that when using the AMB Kress spindle which doesn’t stick down very far, had to use a secondary wasteboard (sheet of old ply) to space the workpiece up for using the small bits (1/8" etc.) and got in the habit of double checking the Z wheels were still on the rail at full plunge for the workpiece.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.