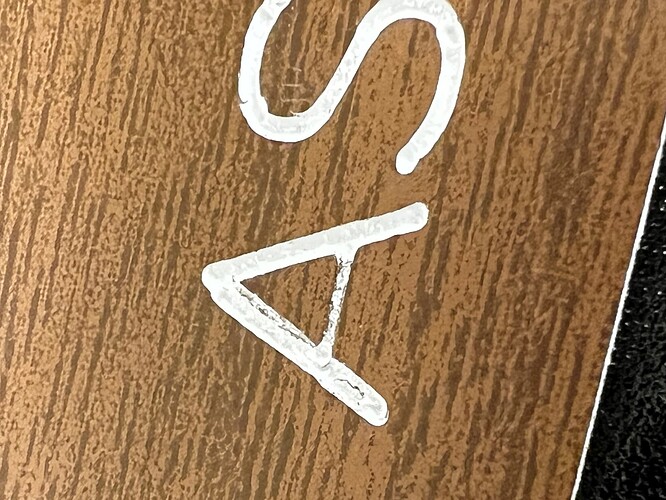

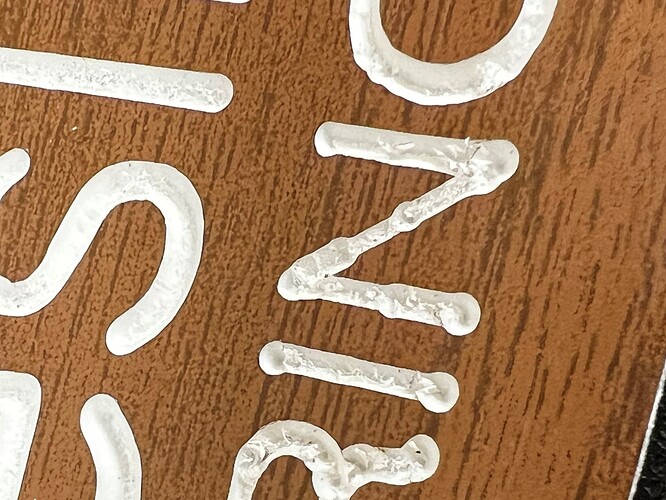

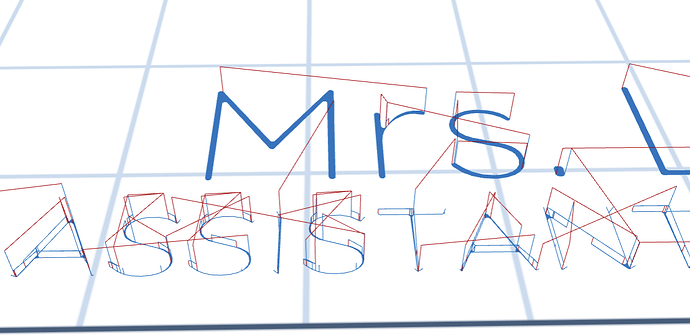

A tech from Inventibles has already fixed the N on the tool path, it was skipping the middle section. On the A its very lightly connecting the two legs with one pass only, other segments of the letters get several passes which explains why the middle of the A is weak. The entire unit is brand new. Why cant it just draw the letters? It jumps around all over the place - isn’t that a tool path? On the preview everything looks perfect! If the bit was too big for the corners, it would show in the preview. The machine only does what the tool path tells it to… it jumps all around. No wonder there are sooo many inconsistencies. The only thing that is consistent is that every time you start a new carve it does the same thing over and over. I have moved the piece around on the board, turned it 90 degrees - no matter what - it creates the same “flaws” on the same areas of each letter.

you can see in the N - it was skipping the middle, even after the 'fix" by the tech it still does not look very good.

Please make a basic, simple test file using Carbide Create.

Cut that file, and post it here along with step-by-step notes on how you are securing your stock, setting zero relative to it, and managing all tool changes and a photo showing an attempt at cutting still in place on the machine.

Possible issues:

- mechanical (we gave you the list above)

- software issues — assigning the wrong V angle will cause problems

- feeds and speeds — losing steps due to wrong feeds and speeds can cause myriad problems

- a setup issue — not getting the origin correct relative to the stock can be problematic

We need more information. What machine, and what software are you using?

When you said you had the same issue, I (we?) assumed you meant the rounded corners (dogbones), Now you are describing a different problem that could also have more than one cause. ???

What software is that?

I recently got a 5 Pro and had a similar-ish issue a couple weeks into using it. What caused my issue is probably not your problem (poor pre-assembly before shipping), but I would check the tightness of you stepper motor couplings just to be sure. I had at least one coupling come just loose enough that it would only slip on the corners, or more specifically when that particular motor started up. That slight slip created issues in the corner of a majority of my details.

Only throwing this out there because I am not sure I saw this specific suggestion. Good thing to check either way.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.