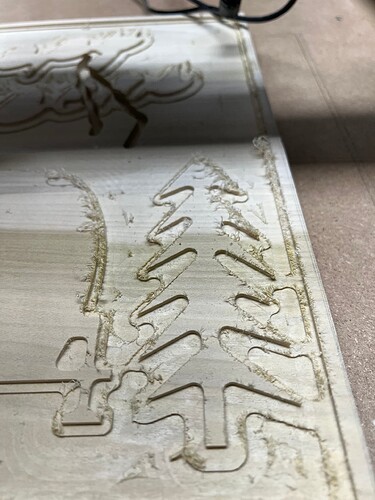

I was making a sign out of Poplar using a brand new 1/4 bit. It leaves it very ragged. Has anyone experianced this? Do I need a different kind of bit?

What tool are you using?

I’d suggest a #251 downcut.

yeah its common with many wood species, the bit is most likely an upcut bit, but is easily remedied with a quick once over with brass bristle brush or a stiff nylon brush. you can try switching to downcut bits to minimize this in the future.

I’m using the #201 but I’ll try the $251 on the next sign.

I’d try a different wood. No matter what bit you use, you will cross a grain pattern that will bring up the fuzzies; if not at the borders then it will be in the pockets. You can do it, but be ready to spend time in clean up.

When this happens to me, I bust out my torch and just go over the whole piece with the flame (very lightly). The little fuzzies will just burn away and it adds a cool look to the piece.

Or you can use a Dremel tool with a nylon brush.

On the right side there is more fuzz. Likely on the right side the bit was heading up the tree while on the left the bit was moving down the tree. So when you go cross grain which in this case you are you get more tear out because the bit is cutting unsupported fibers of the wood. On the left side the is still fuzzing but the fibers are more supported due to the direction of the bit. You could try as suggested the #251 down cut bit but you may still have some fuzz but less. You could also try orienting the project 90 degrees. It just depends on the amount of cutting that is cutting cross grain. 90 degrees may still get fuzz but if the bit is cutting cross grain less you get less fuzz.

I routinely stain then spray my stock with lacquer before carving. I really helps with the fuzzies and creates a good contrast. The lacquer remaining on the uncarved stock helps with painting and counter-staining.

This topic was automatically closed after 30 days. New replies are no longer allowed.