I recently obtained a couple of Vacuum attachments to test and evaluate from “burgchevap” aka Andrew. These are now available to order from http://www.ev-guide.com/3d-printing-products/shapeoko3vacuum , and the first orders start shipping Sept. 12th. Feel free to contact him directly.

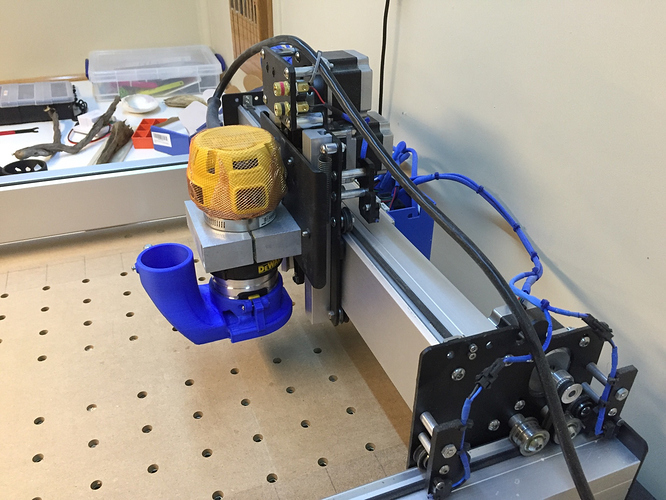

First off, the quality of the 3D print is solid and it’s a good looking piece. You can order it in black, silver or blue, but I think a really nice benefit is that for an additional fee (if you are so inclined) you can order it in a custom color that may match your system. It matches very nice with the blue parts on my S3. In real life, it look almost iridescent.

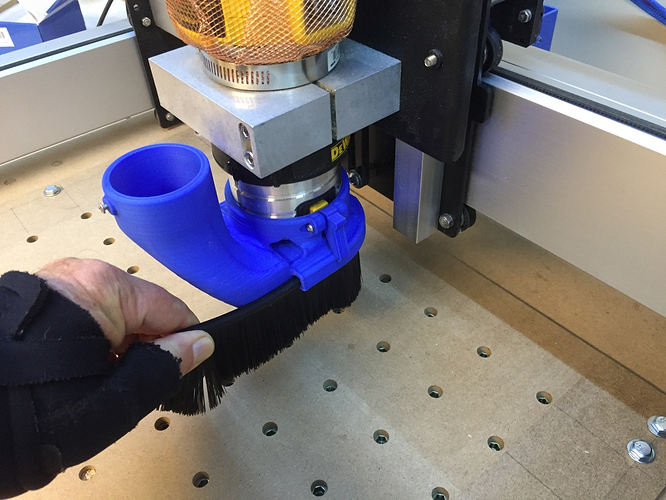

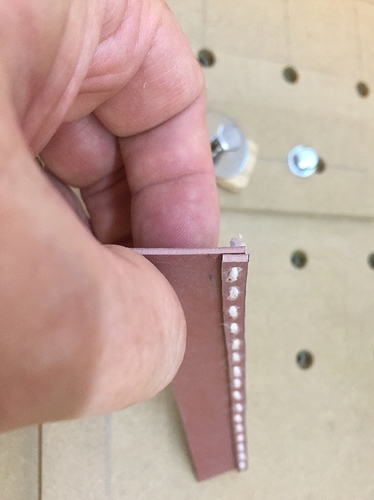

It comes with slide out brush, and there may be some of you out there that don’t what to use a brush for various reasons. Most of my pictures will be without the brush (more later on this).

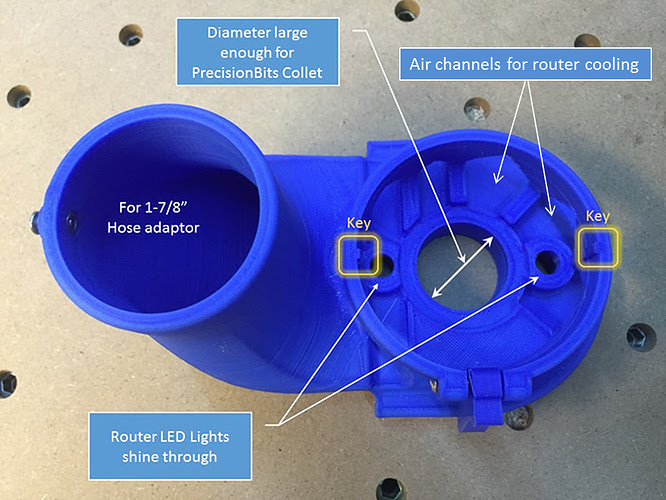

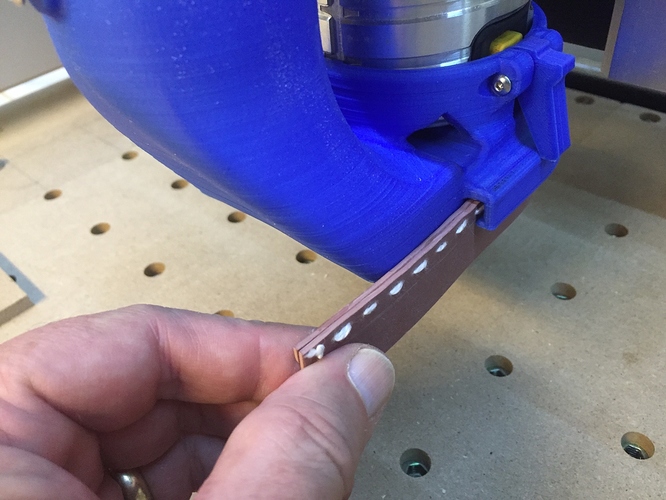

Here is a close up of the top of the attachment with some features.

Note the opening for the LED lights, the keys for a very satisfying mounting on the Dewalt Router (not sure how it would fit any other type) and a secret lever on the right side. (I had to flip my router 180 deg., but no issue for me.)

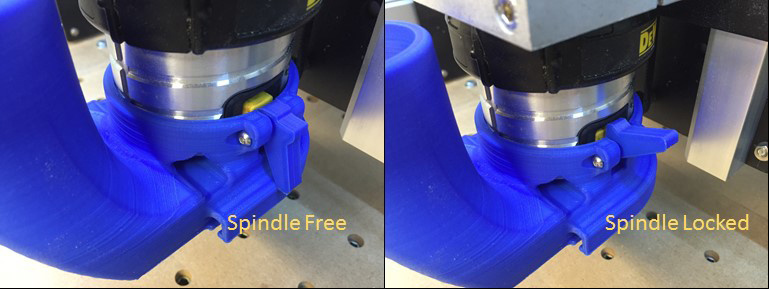

The spindle locking feature is enabling technology to make this a very convenient and easy to use attachment. It works with the old and new Z-Axis plate.

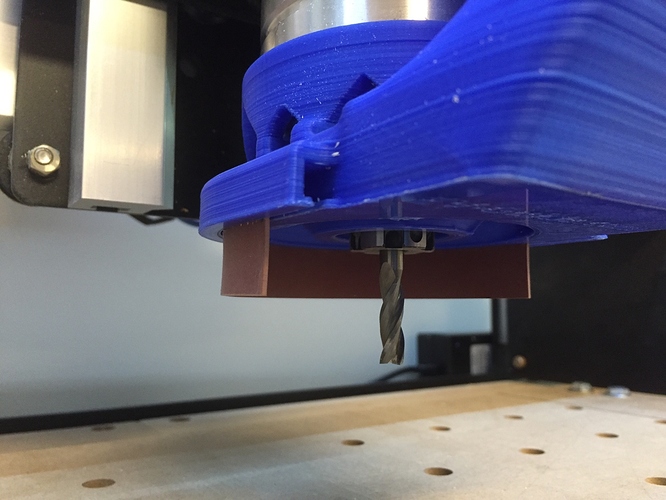

My first concerns were; Does it work with the PrecisionBits Collet? And can you change a bit using the collet tool while it is installed? The answer to both is YES! The diameter is large enough and there is just enough room to use the PrecisionBits special wrench. (The vacuum attachment does comes with a wrench to accommodate the stock style Dewalt collet)

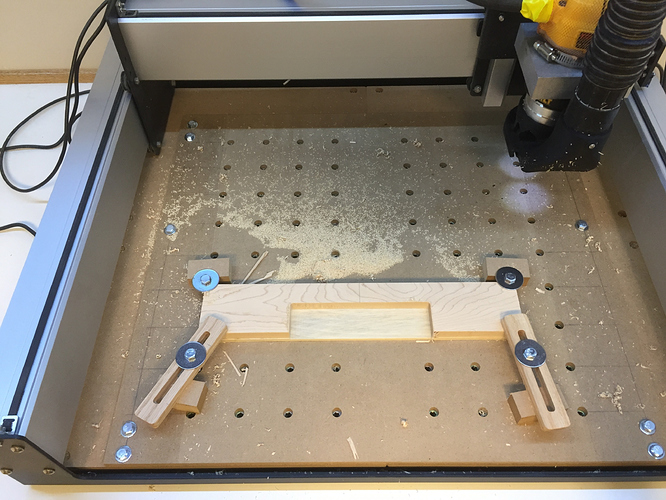

I know it looks tight, but PrecisionBits wrench does work and using the Spindle Lock feature, I can use it without looking. Now the brush might make this action inconvenient but I haven’t tried this out yet. I took the brush out mainly because 90+ percent of the wood chips are captured without any brush. The below picture show a piece of maple with a rectangle hogged out as a “Pocket” cut, meaning doing it the long way and creating a lot of chips. You see the total amount of remaining chips and most were thrown back. It is possible to make your own custom skirt to suit your needs.

I am not sure about deep groove clearing and other materials, but I am happy with what I saw. I think a just a section of brush around the backside would also make a big difference and still enable easy use of all the features. What I observed was the immediate area of the bit was pretty much vacuum cleaned for the duration of the project.

I have been waiting some time for something like this. If you are looking for a good and cool looking vacuum attachment for your system, I am sure you will find this one pretty darn close to ideal.

I looked at many of the make-your-owns and 3D-print-your-owns as well as designing one myself, but this one had several merits(spindle lock, viewing my work, removable brush) that made this design stand out amongst the others. I’ve only had my machine built for a week now and really just want to get running on my own projects without reinventing the wheel. I’m kinda surprised that there isn’t a C3D add on for free or purchase, or “first project” that addresses dust collection or more specifically the dust shoe itself. With one of my 3D printers the first included project to print was a fan shroud for cooling prints, the printer came with the fan and instructions as well as the needed files for printing and completing the project, I thought that was really cool, test the machine and get a useful part at the end, much like the hold down clamps provided by C3D. This one however looks like a winner, at a reasonable price, we’ll see when it gets here.

I looked at many of the make-your-owns and 3D-print-your-owns as well as designing one myself, but this one had several merits(spindle lock, viewing my work, removable brush) that made this design stand out amongst the others. I’ve only had my machine built for a week now and really just want to get running on my own projects without reinventing the wheel. I’m kinda surprised that there isn’t a C3D add on for free or purchase, or “first project” that addresses dust collection or more specifically the dust shoe itself. With one of my 3D printers the first included project to print was a fan shroud for cooling prints, the printer came with the fan and instructions as well as the needed files for printing and completing the project, I thought that was really cool, test the machine and get a useful part at the end, much like the hold down clamps provided by C3D. This one however looks like a winner, at a reasonable price, we’ll see when it gets here.

. Had I not been in the shop to stop the system it would have been a disaster.

. Had I not been in the shop to stop the system it would have been a disaster. .

.