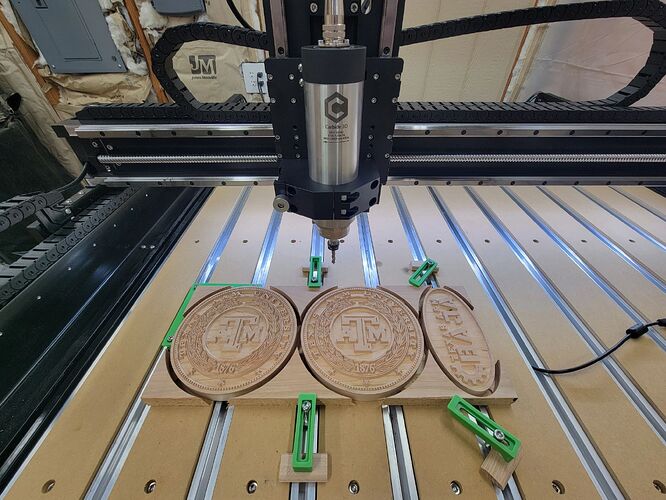

I am wondering if anyone has tried to use a sandblasting pen with very fine sand to smooth the tight spaces in the depths of the V-bit passes. If you look closely there are little chips and flakes that I want gone for a more apparent smooth finish, and I can’t get in there with a detail sander so I was wondering if anyone has used a small sandblasting pen to get in the tight spots and how it has turned out. Or what else yall do to get a smooth finish in the tight spaces without dedicating too much time to it?

Some folks have re-run a full-depth V carving to clean up such fuzzies, another option is a small nylon or metal brush. The traditional tool would be a veining tool of a suitable angle.

I second @WillAdams but if you try sand blasting I would try baking soda and not sand. It would be very hard to get small enough sand and you will likely obliterate your carving. I have seen DIY sand blasters using soda bottles on youtube. Just dial your air pressure from very low to just get the flow and try that. Wood is relatively soft and would get blasted away quickly.

I have some sand blasting to do this week. I have a 50’s 30" Duro scroll saw taken apart that is cast iron. Today I went and bought a 70’s Delta/Rockwell radial drill press that is in good shape but will blast that at the same time. I have to sand blast in the winter because past March it gets way too hot here in East Texas for all the protective gear. I still get sand in my ears some how. I will trying glass beads for the first time on this equipment.

My GrandFather would take his parts to a shop that used walnut shells as a blasting medium. I did not believe it would work. I saw the before and after he got it back. I was amazed at how great it looked

I used to shoot in competition and reloaded thousands of rounds. I used walnut shells to clean my brass.

Eventually it wears out but not for a long time. Plus you pour in some polishing compound every once in a while.

Milling walnut is easy because it is a softer hardwood. It cuts well on my Shapeoko. The shells are another story. Just watch a squirrel try to break one open.

Squirrel gottta get his nut.

I cannot help at all BUT, I would love to get the stl for the ones on the left, if you could point me in the right direction.

I have several friends that graduated from TAMU. I do some work for SFA and have gotten permission to use the official SFA logo because the projects were for the university itself.

I have been told by multiple people that TAMU is very picky about using their logo and will file copyright infringement for commercial items. Making one for yourself or family is not likely to flag TAMU but just beware that using a copyrighted logo can get you in trouble. This subject has come up on the forum multiple times.

I assume that with all universities and brands. Zero interest in selling this type of work. It looks great for personal use tho.

I would think the threat to sue would counter the call every other month requesting alumni to donate.

I did some plasma work cutting logos for some of their buildings during construction awhile back. At that time I had to convert the image because they would not provide dxf files. This was for construction contractors not directly to the university.

Sorry Ashtonb912, I did not intent to highjack you post. I will stop.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.