Context: I purchased some cad files for a guitar which is set at a scale that doesn’t match the guitar and it has all of the components in the one file. I use carbide create and am fairly familiar with it but haven’t done this process before. I’ve looked for several hours across the internet and have seen tutorials that are either extremely rudimentary / doesn’t get into enough detail OR complicated to the degree that they assume a very deep level of knowledge about many different cad / cnc software. IE “Import it into inkscape and do it” as though the reader would know how to do that.

Question: Does anyone know of a tutorial that shows the importing, scaling, subdividing, setting tool paths and building a DXF / DWG file from beginning to end?

robgrz

March 29, 2022, 1:34pm

2

I’d bet that if you send the file via PM to @WillAdams (to avoid publically posting a commercial file) then he’d post a tutorial here for you to check out.

1 Like

WillAdams

March 29, 2022, 4:09pm

3

I work up importing a DXF to make a box at:

The interface allows setting the parameters or the box and defining the tools which will be used. Due to limitations in how OpenSCAD defines variables it’s most expedient to require specifying the diameter of the endmills in addition to identifying them.

[image]

Design into 3D_ Box Sawn.zip (2.3 KB)

Once the file is rendered it may be exported as an SVG or DXF which may then be imported into Carbide Create:

[image]

and each section may be grouped and aligned w/ the stock and put on a sepa…

if you’ll send the DXF to me in a PM as Rob suggested, I’ll gladly work up a step-by-step for it here.

1 Like

WillAdams

March 29, 2022, 9:12pm

4

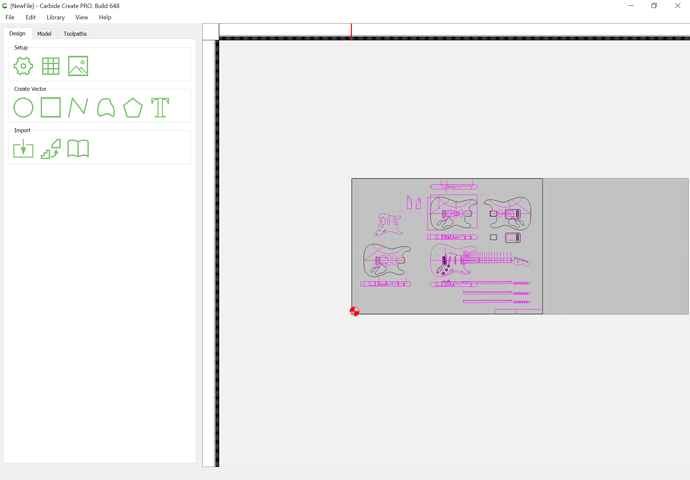

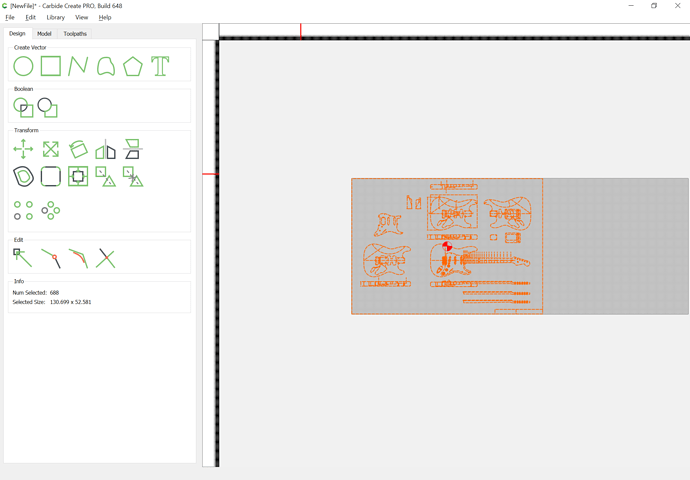

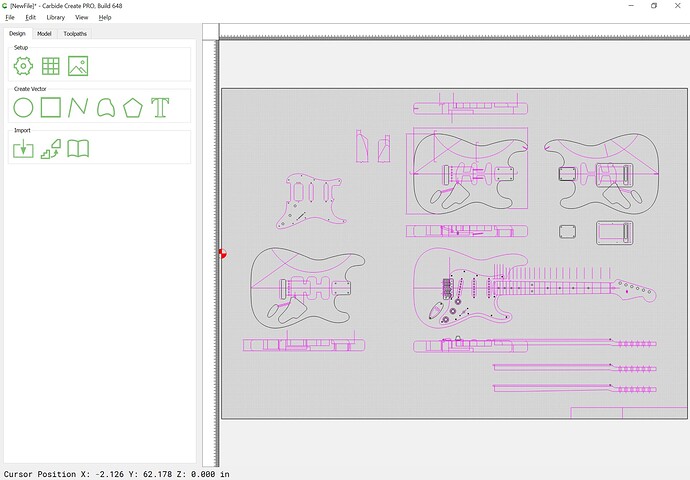

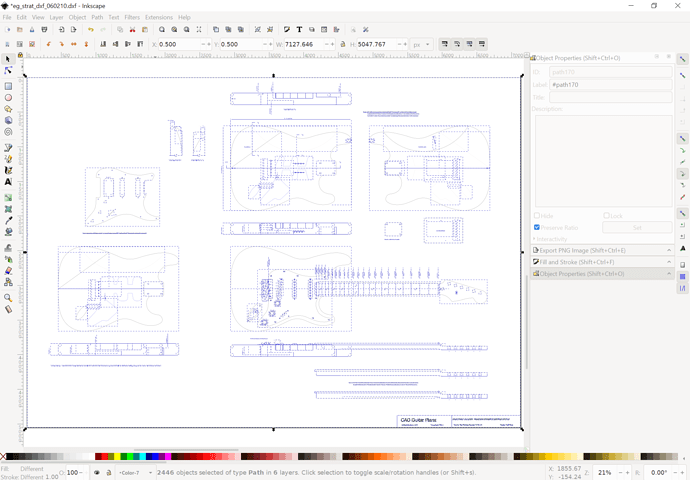

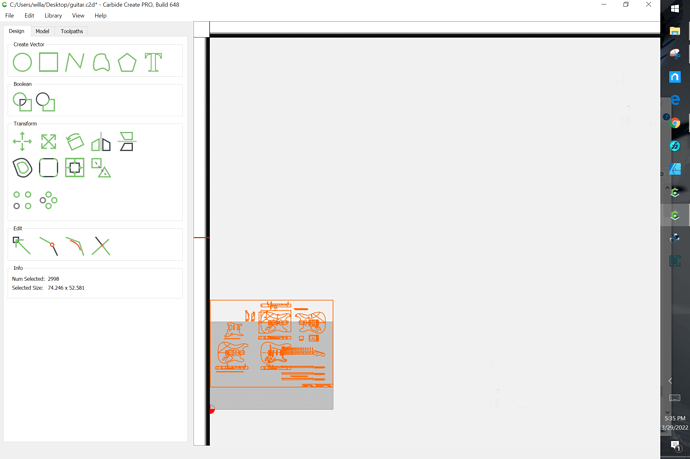

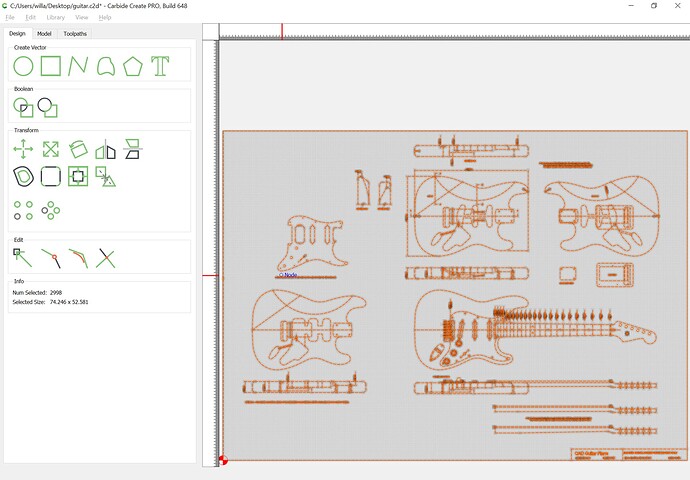

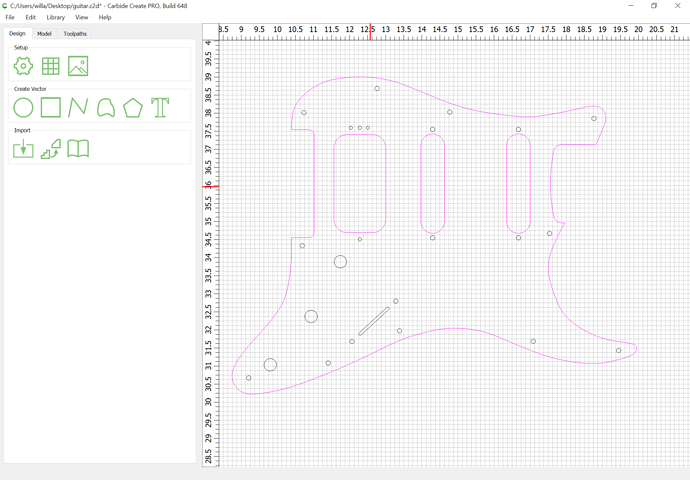

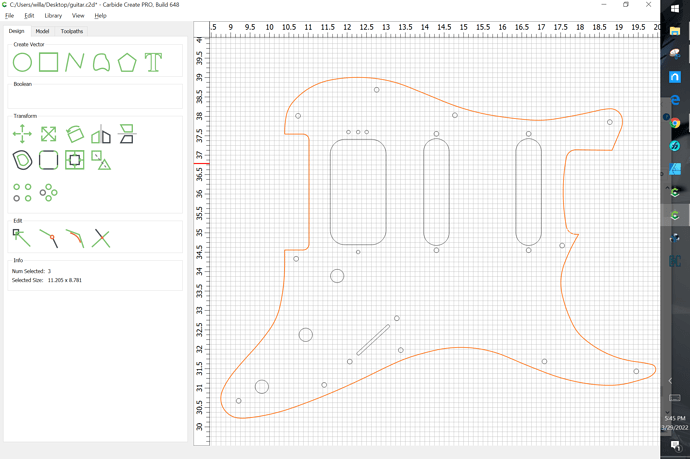

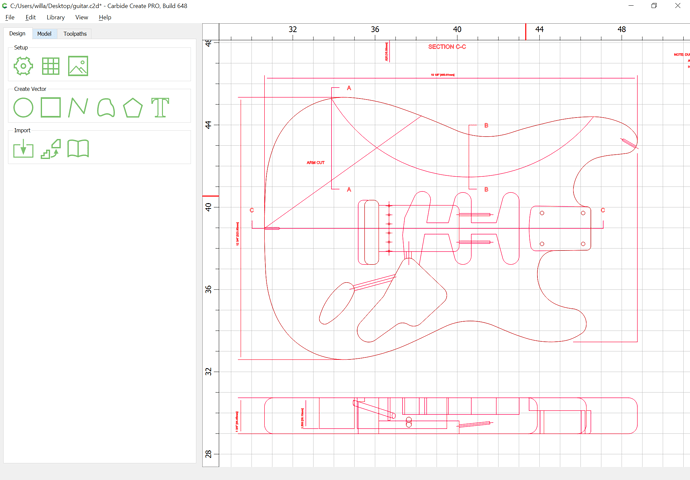

Okay, we import the file into Carbide Create and we get:

which has a couple of issues:

some geometry is open/unjoined when it would be better if it were closed (we will cover how to address these below)

no text/annotations (we will cover how to open the DXF in Inkscape to address this below)

there’s a tiny object off to the bottom left which interferes w/ how things zoom in (also addressed below)

WillAdams

March 29, 2022, 9:25pm

5

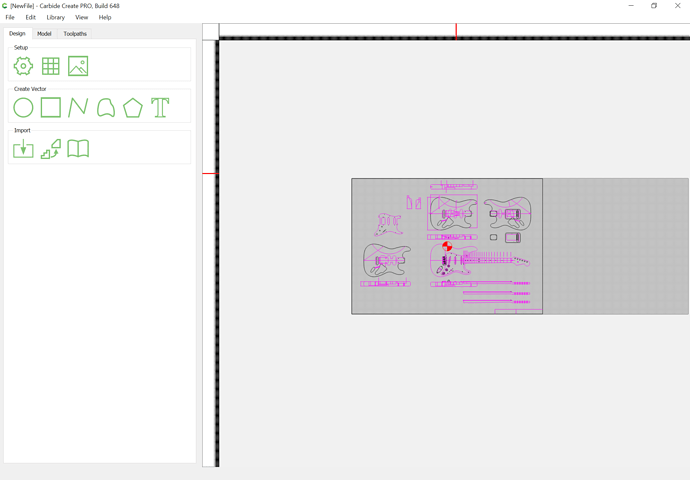

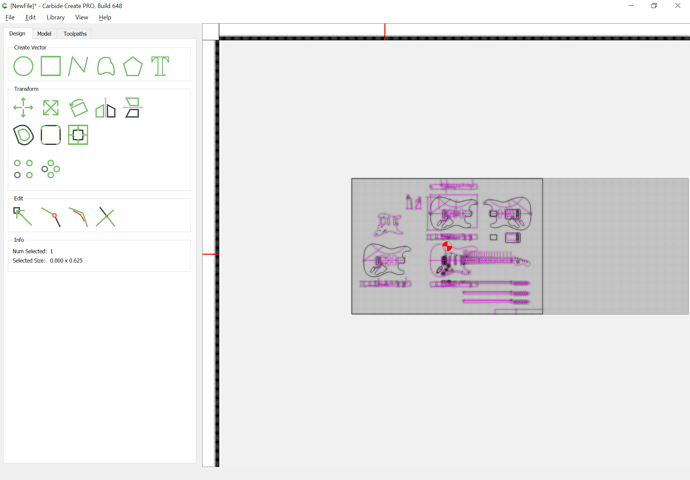

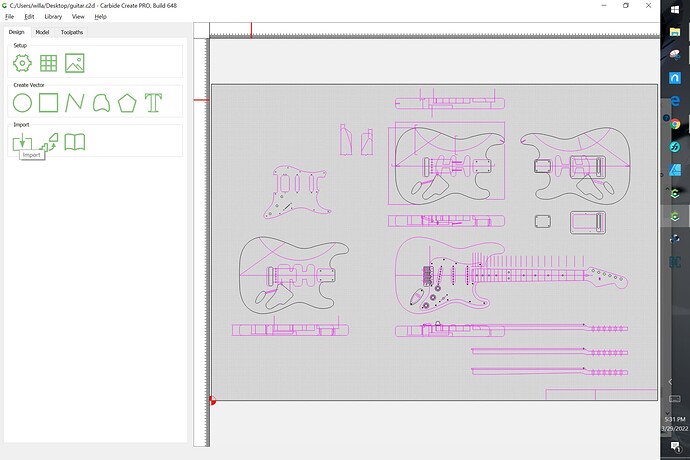

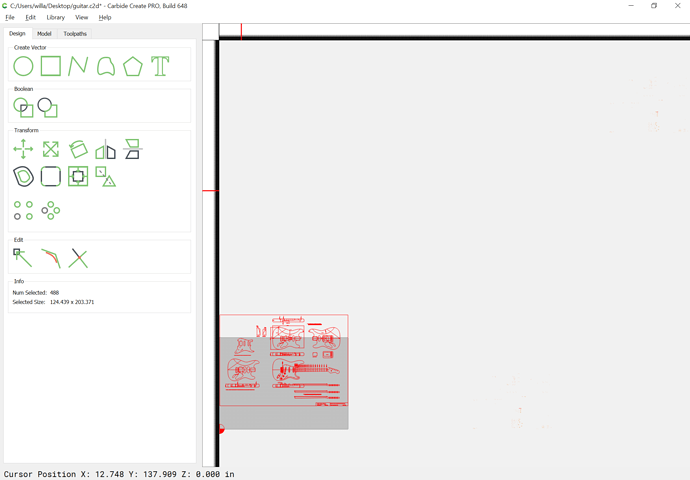

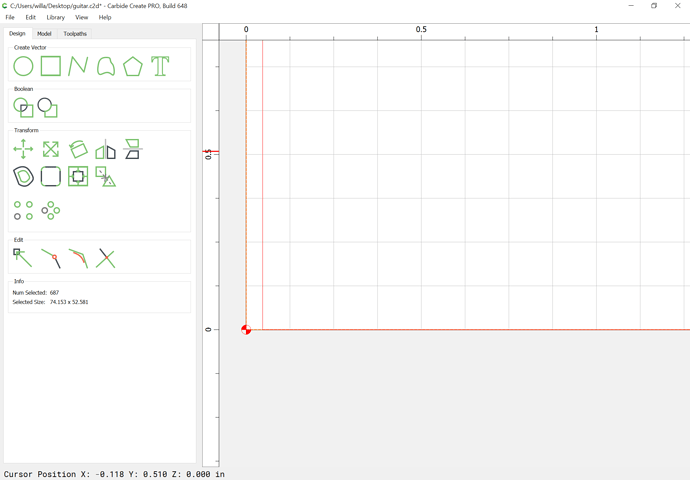

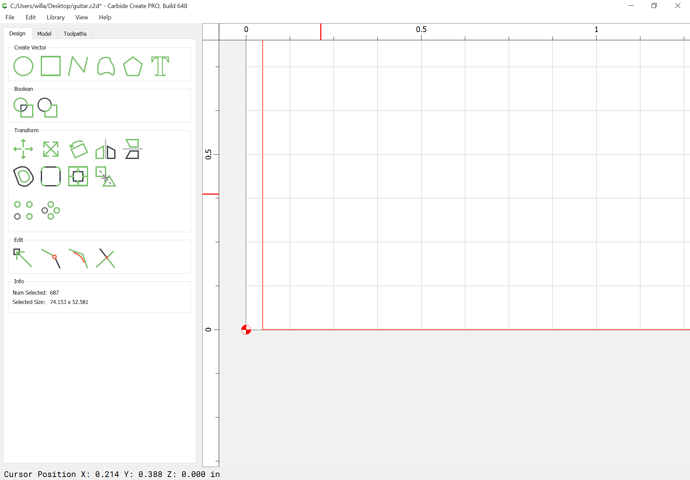

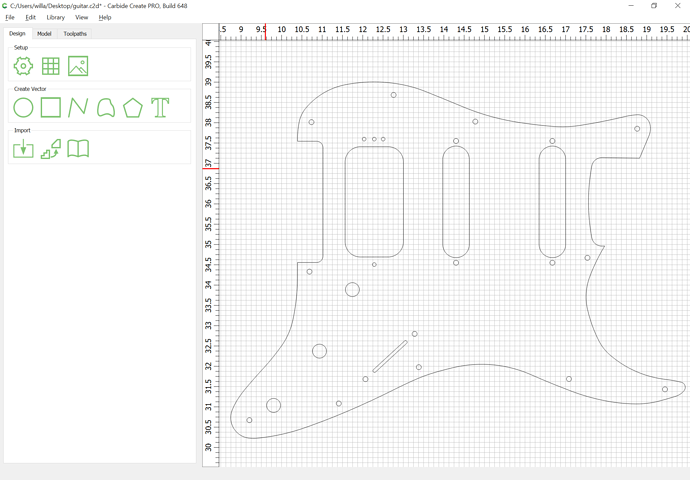

As noted above, when the DXF is opened we get:

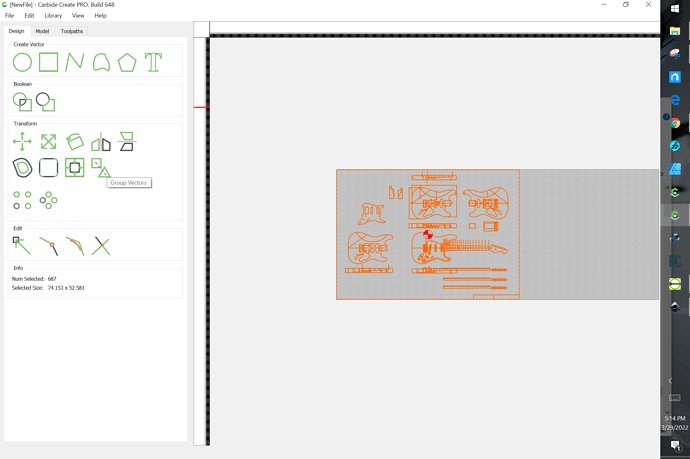

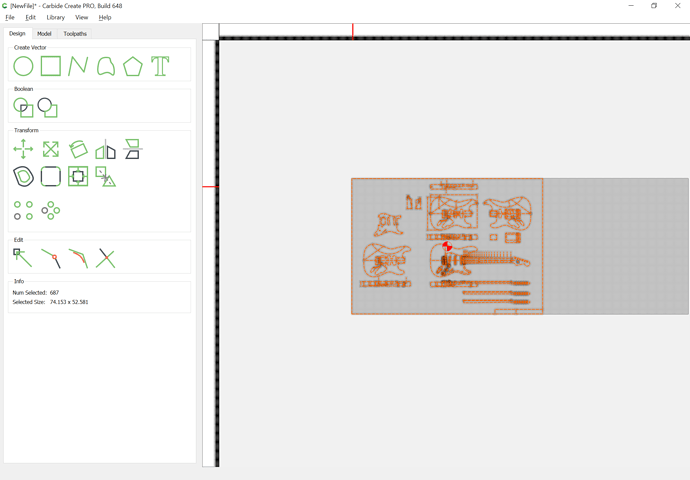

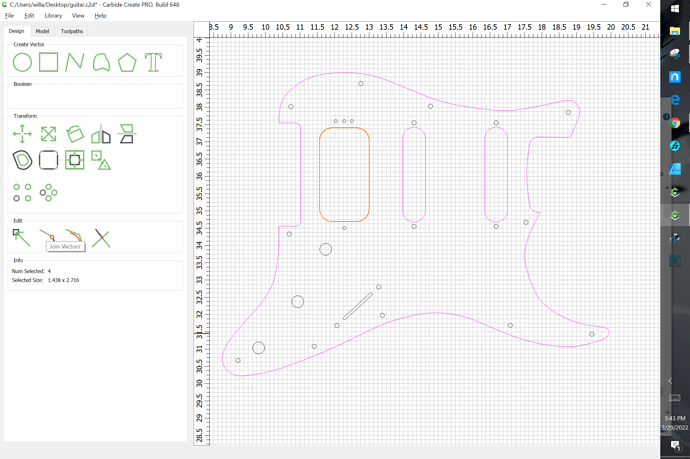

Drag-select to select everything which we wish to work w/:

Group Vectors:

Select All

shift-click on the group which we wish to keep:

delete and fit to screen now works:

A further step — select the selection of things which we wish to work w/ and note the size, deselect, bring up Job Setup:

and update the size:

save the file.

WillAdams

March 29, 2022, 9:31pm

6

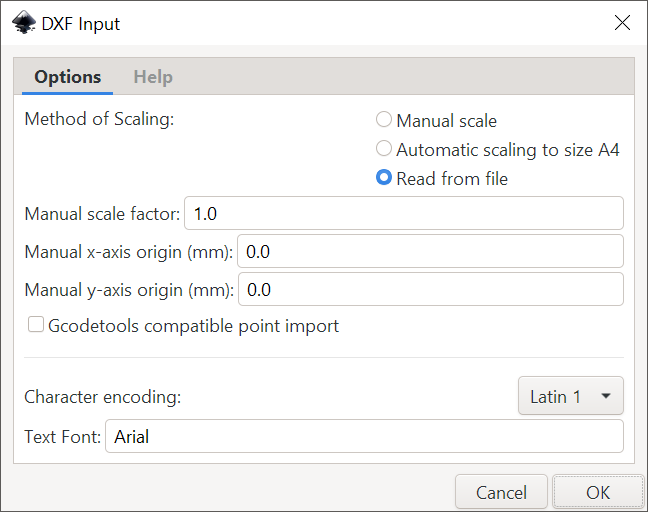

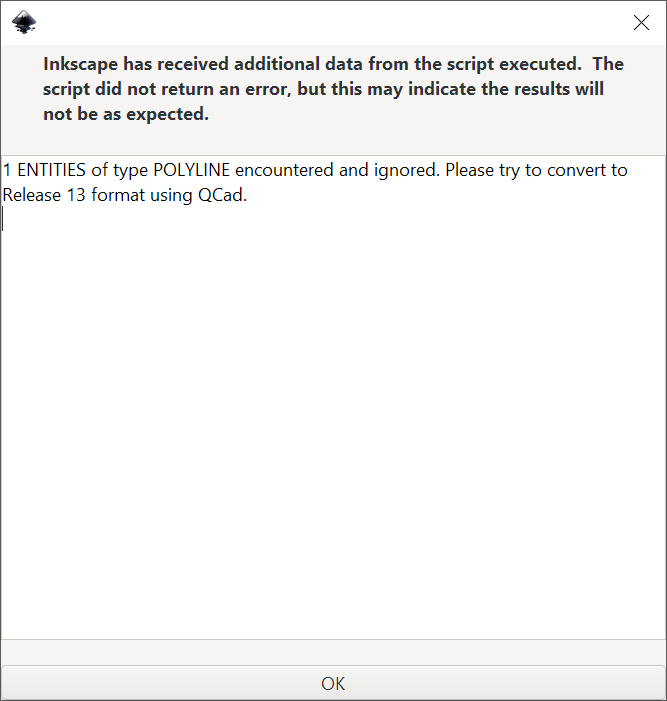

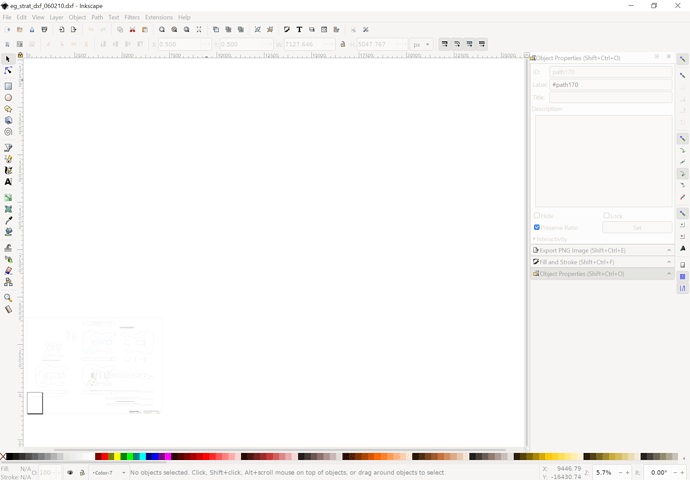

As noted, there is text on the DXF which Carbide Create does not bring in — it is a simple matter to open the DXF in a 3rd party tool and convert it into geometry so that it may be placed on a background layer for reference.

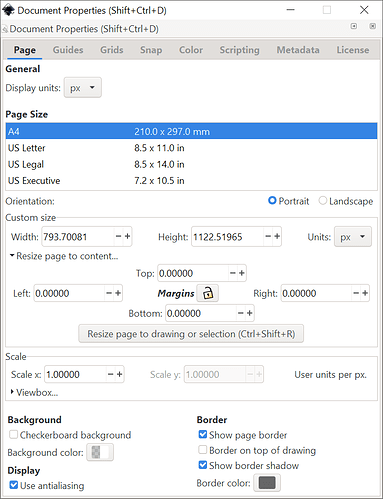

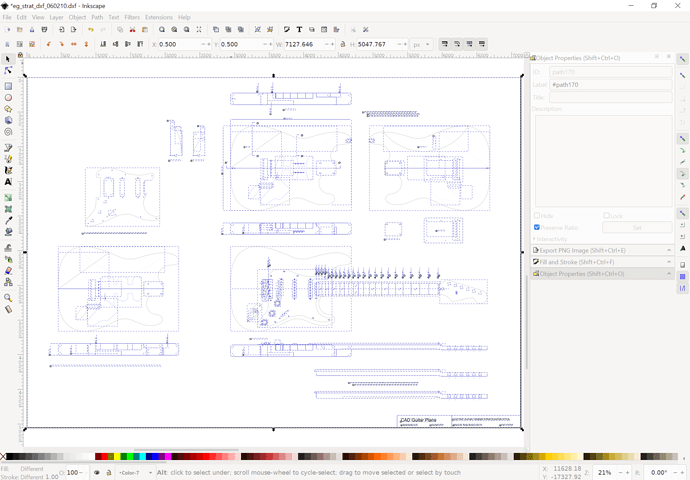

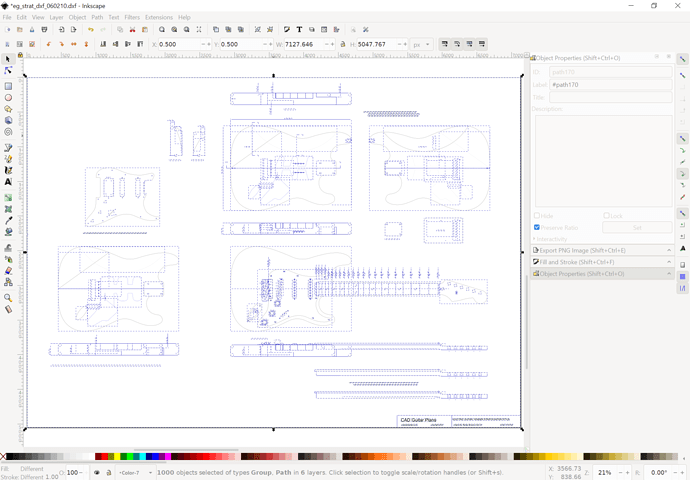

Open the DXF in Inkscape:

OK

we get a warning message:

OK

View | Zoom | Drawing

Drag-select to select what we wish to work w/

File | Document Properties

Resize Page to Drawing or Selection

View | Zoom | Page

Path | Object to Path

Object | Ungroup

Save as an SVG

WillAdams

March 29, 2022, 9:39pm

7

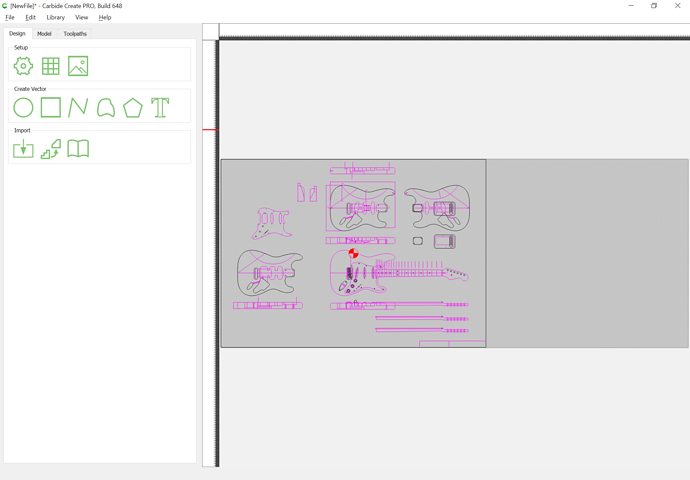

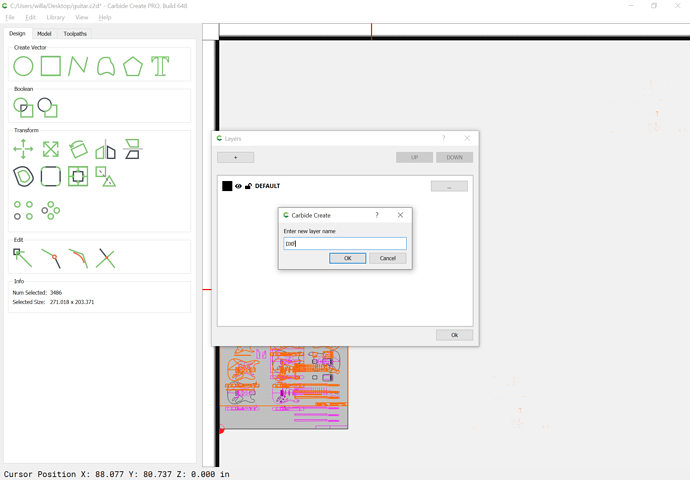

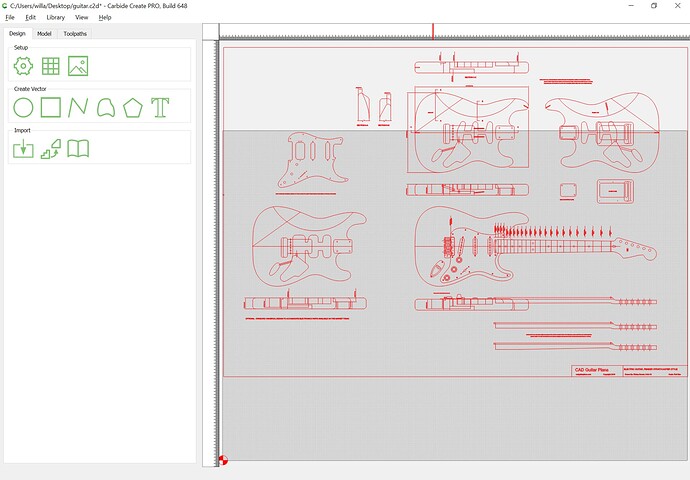

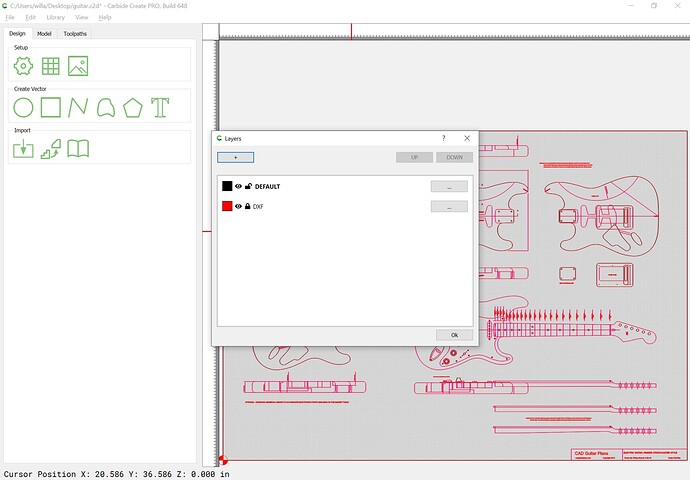

In Carbide Create Import the SVG:

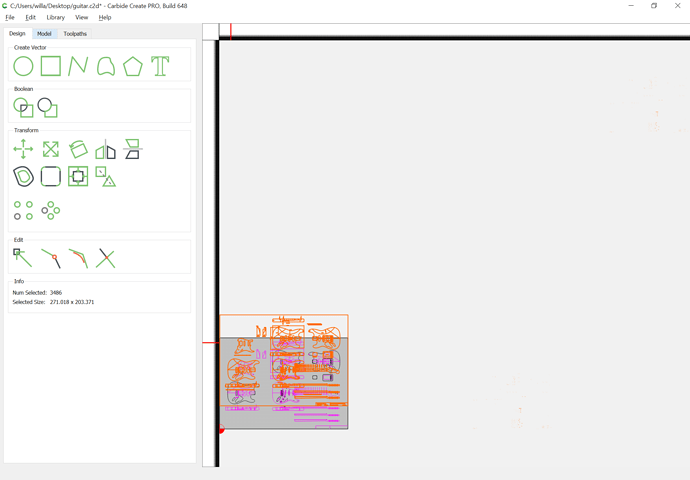

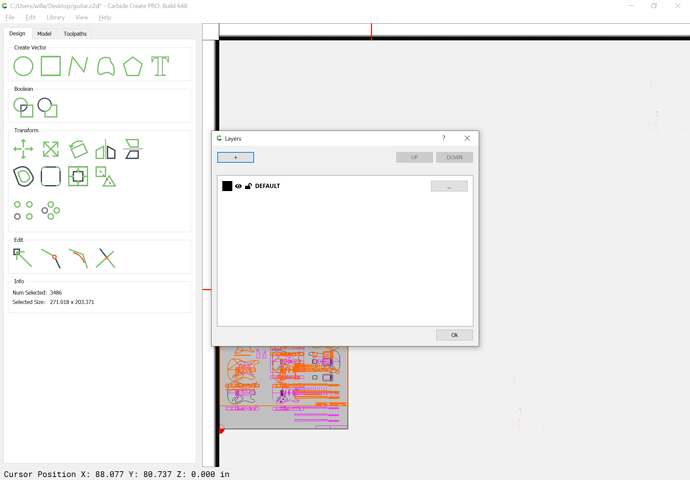

Bring up the Layers palette:

make a new layer:

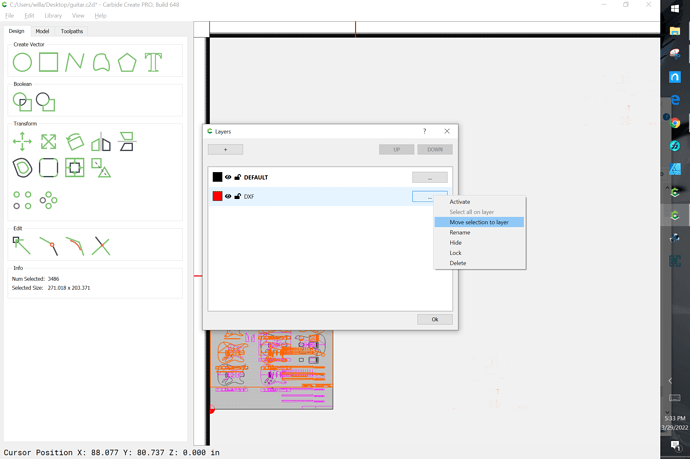

Move Selection to Layer:

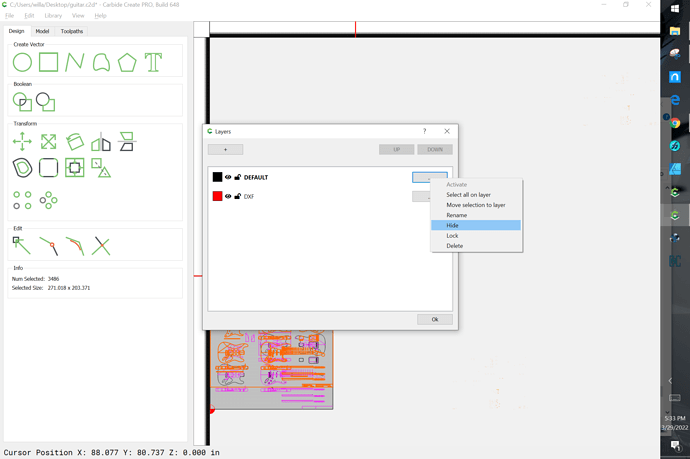

Hide the Default Layer temporarily:

OK

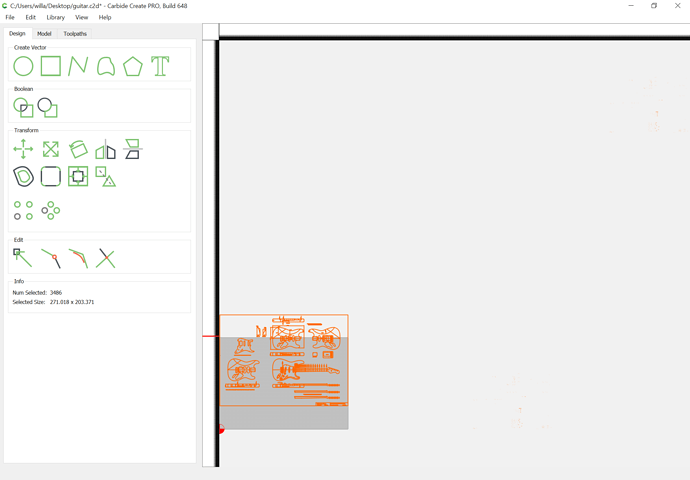

Again, select everything which we wish to work w/

Group Vectors

select all

shift-click on what we wish to keep:

delete

Fit

Use the Align pane to center things:

Bring the Layers palette up, lock the DXF layer and show the Default layer:

WillAdams

March 29, 2022, 9:41pm

8

If things don’t line up perfectly, select everything on one layer, zoom in:

and drag to align things:

WillAdams

March 29, 2022, 9:47pm

9

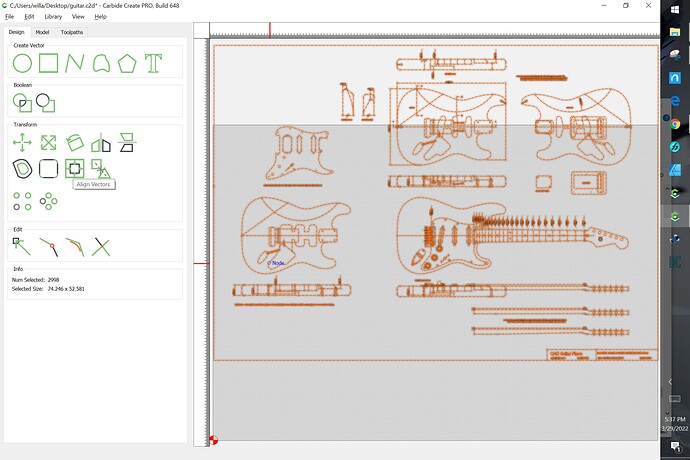

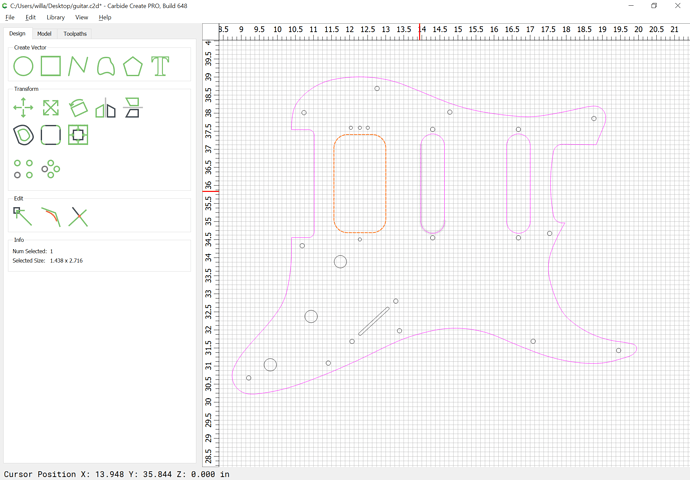

Zoom in on a section which we wish to work w/ and hide the DXF layer so that the state of the objects becomes obvious:

Ungroup

Select sections and Join Vectors to close them:

Repeat as necessary:

Note that in some instances it may be necessary to repeat the Join Vectors command:

WillAdams

March 29, 2022, 9:58pm

10

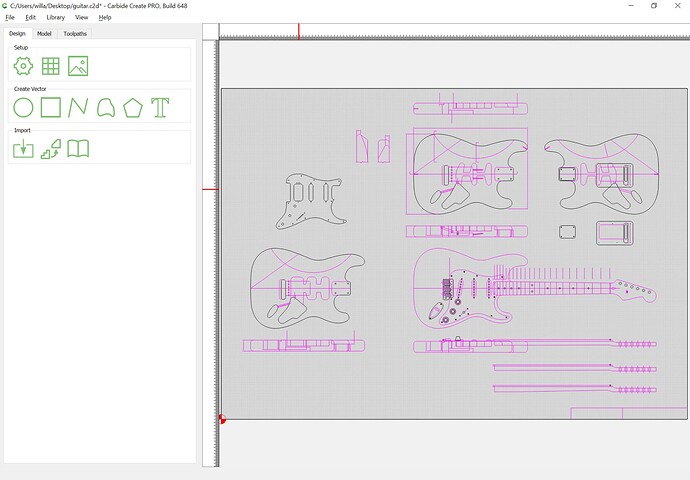

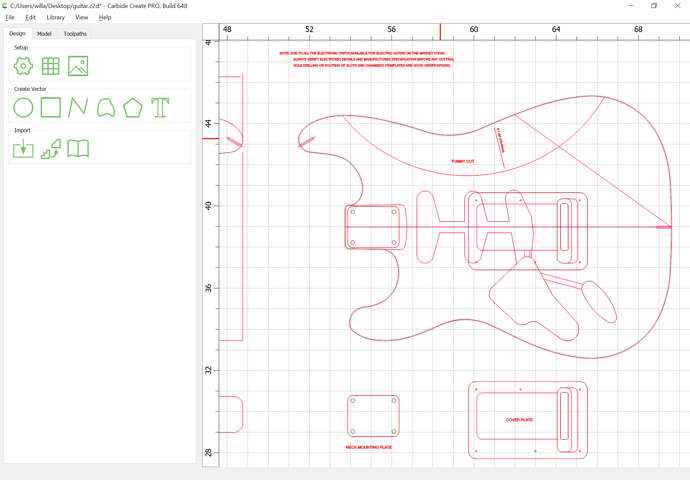

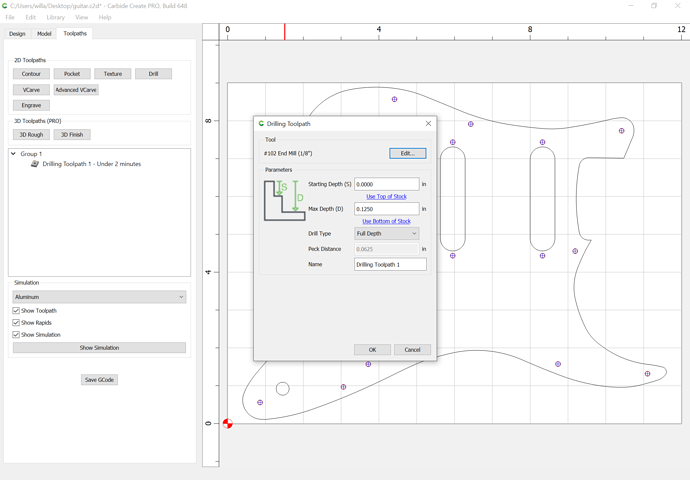

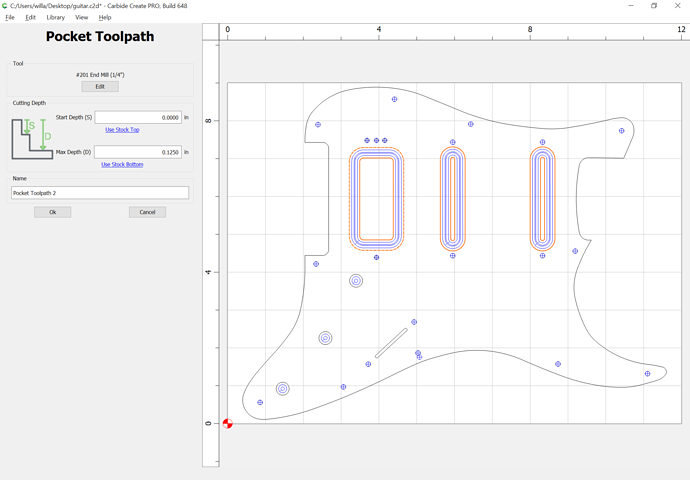

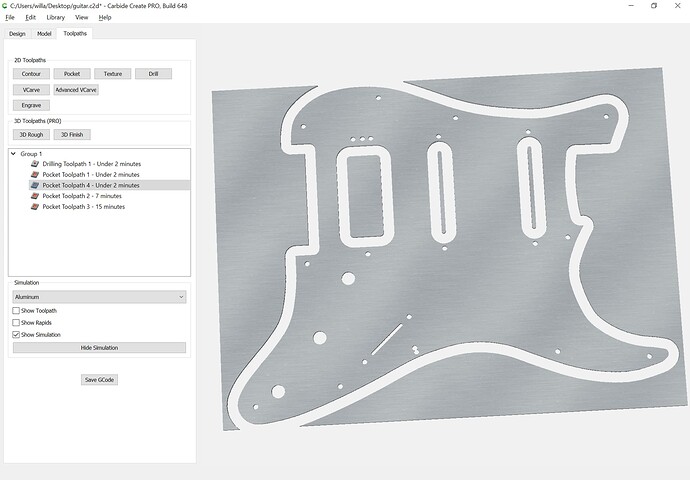

The balance of things will be specific to the electronics which one has selected, but basically:

Cut out the pockets and drill holes for necessary features/parts

Do 3D modeling or work up suitable toolpaths for features such as the “Tummy Cut”

work up a suitable technique to flip the body to cut the features on the other side:

If you get stuck, let us know at support@carbide3d.com and we’ll do our best to work through any issues w/ you.

Will send the .c2d file via PM.

1 Like

WillAdams

March 29, 2022, 10:21pm

11

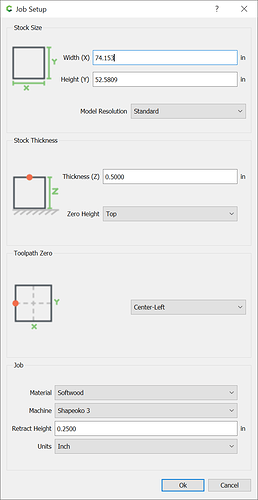

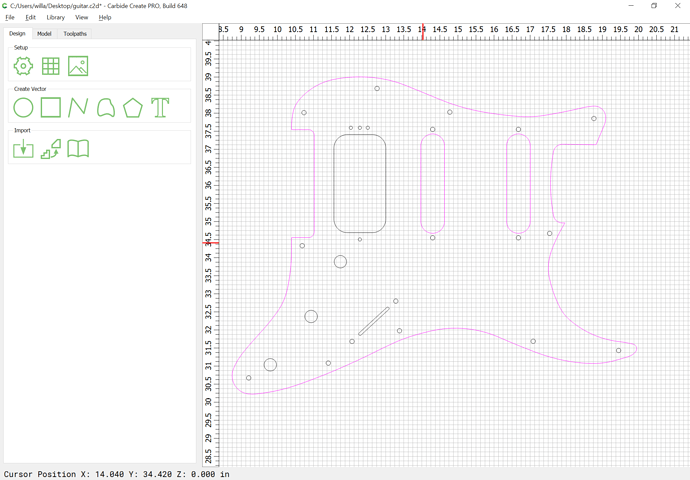

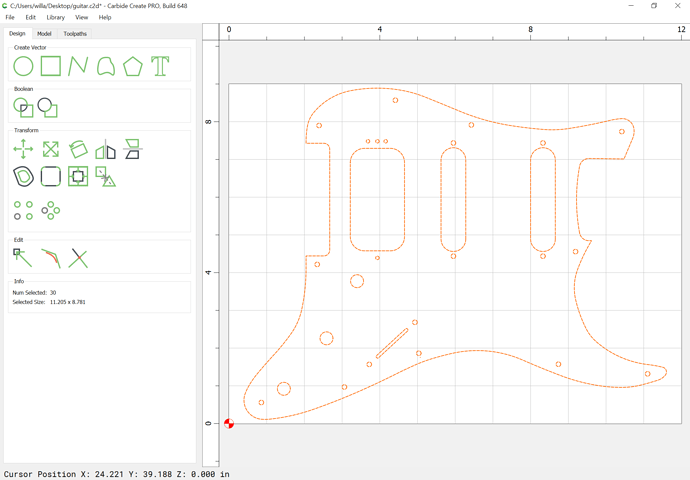

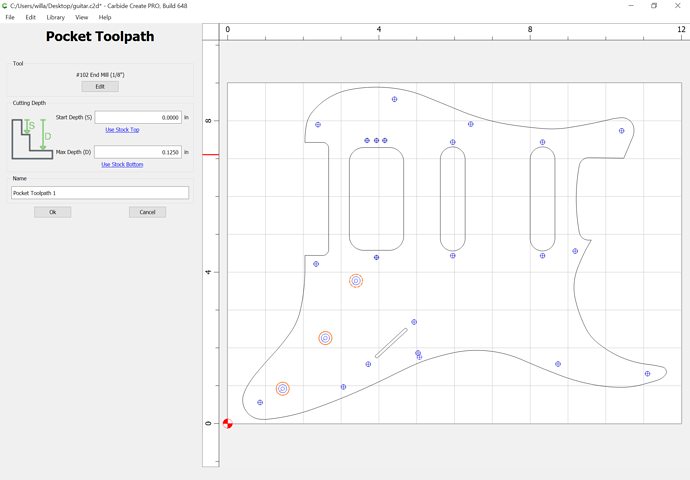

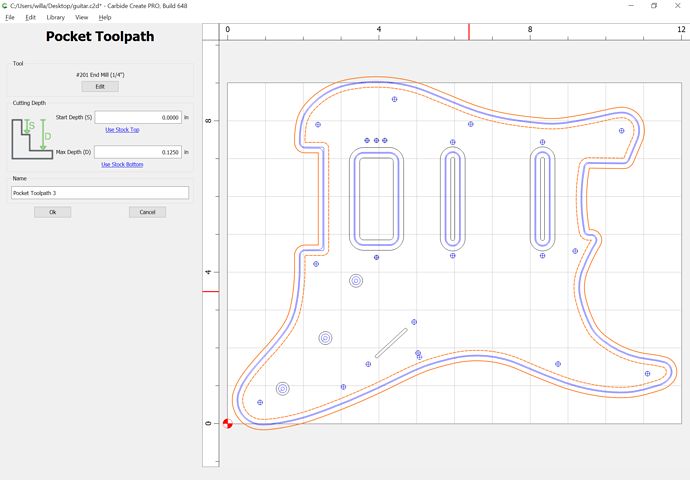

Once one has the file prepared, duplicate the file for each part which will be cut w/ a given operation and delete everything which isn’t necessary:

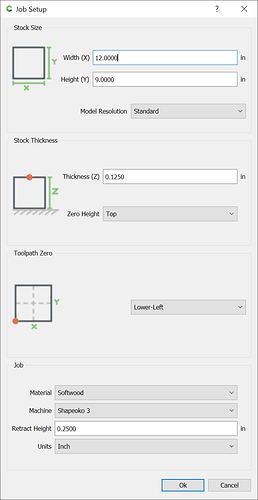

Set the stock size and thickness to match the stock you have:

Then assign appropriate toolpaths:

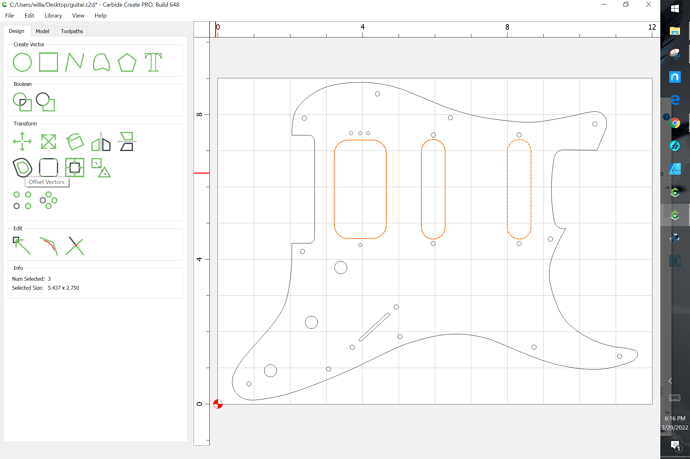

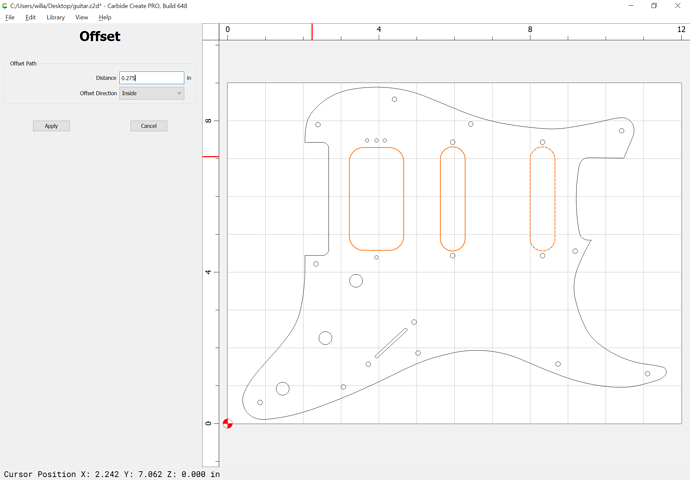

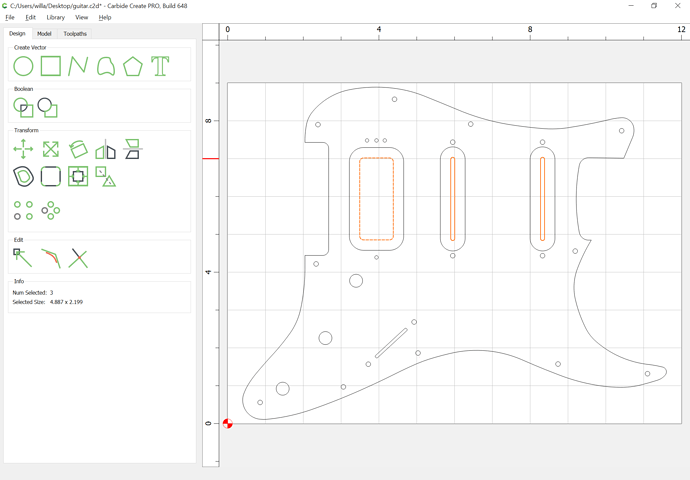

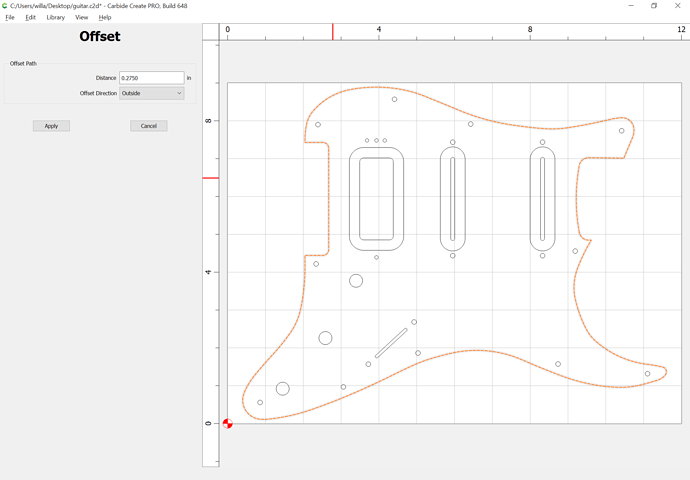

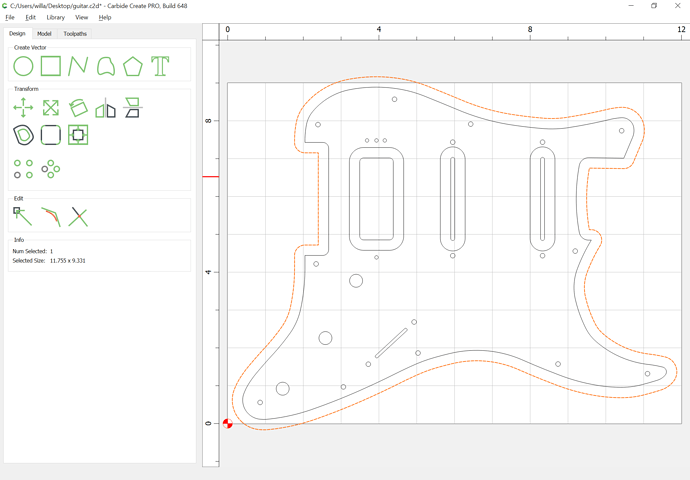

Where necessary offset geometry:

and to the outside for the outer profile:

2 Likes

system

April 28, 2022, 1:21pm

12

This topic was automatically closed after 30 days. New replies are no longer allowed.