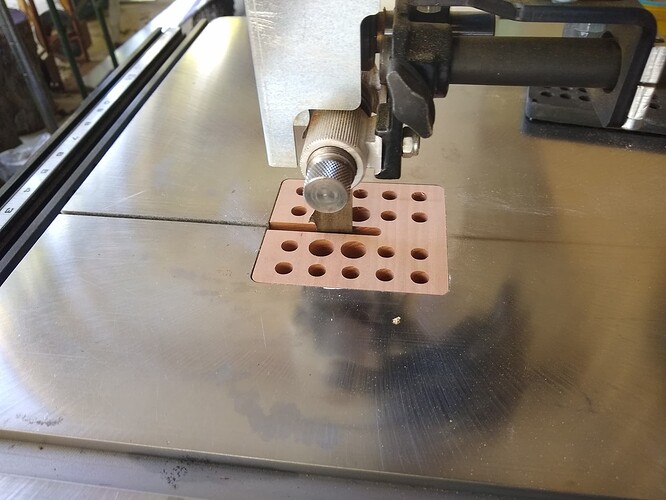

I have an SCM 16" 3HP Bandsaw. The machine is great but the plastic throat plate is pitiful compared to the rest of the machine. I had made a new throat plate out of oak but it had cracked. I was going to use the bandsaw today so I quickly drew up a new throat plate and cut it out on my Shapeoko 3 XXL.

The original plastic one had screws that you used to level it. i just measured the bottom of the screw to the top of the throat plate and milled some cherry to that thickness so I dont have to hassle with the leveling screws.

The oak throat plate I made broke because I had the long grain running parallel to the throat cutout. This made the plate weak. On the new cherry one I made the grain perpendicular to the throat cutout so I get the advantage of the grain direction which is stronger at this angle than the oak one, I also made some design changes to the dust holes and made the one close to the blade bigger. Drill Presses make more mess in the shop closely followed by the bandsaw even with dust collection.

I made an outfeed table that can go on the side or the back. I used quick release toggle clamps on a bracket to clamp to the table. Then the extension has threaded inserts in the bottom of the table and the clamp piece has holes drilled so I put 1/4’20 knobs to hold the table to the clamping base. I use a Wixley digital angle gauge to set zero on the bandsaw table and move it to the extension table to level that with the adjustable leg.