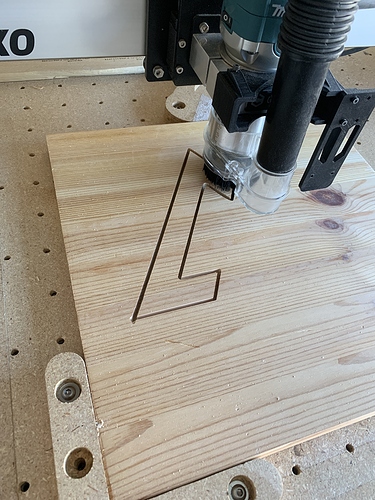

Any suggestion on why this is occurring? The first part of this cut it started on the surface and went progressively deeper. On the second group of vector cuts it started well above the board cutting air. Board is level as is the surface of my shapeoko 3. Just wondering if anyone had any insights I’m not a seasoned vet at this.

Without seeing the .c2d file and G-Code, the likely problems are:

- lost steps when plunging if you have a belt drive

- error in how a tool change was managed

Please post a .c2d file, generated G-Code, step-by-step notes on how you are securing your stock and setting zero relative to it, and managing tool changes and a photo showin an attempt at cutting still in place on your machine.

Thanks for the reply. It cut after missing the first pass on all but the first section. I’m going to check a few things re-zero to the stock and run another one see if it persists. Probably user error.

Of note there wasn’t a tool change involved.

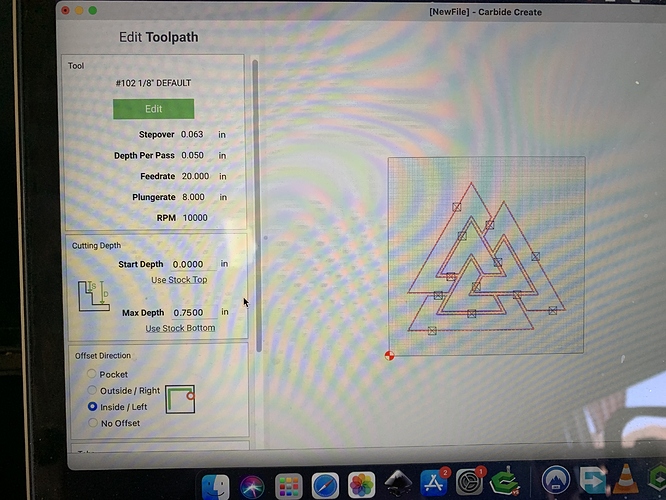

Unless the gcode is jacked you are losing steps on the Z after the first cut. If it is Carbide Create creating the gcode I would discount the gcode jacked. If you are making the gcode with another application then it may be possible it is the gcode.

Check your belt tension on your Z, it appears to be a belt driven Z in the pictures. Also compare your feeds and speeds with the recommended F&S from the tool in the tool path generation. It is possible you have changed the F&S by accident.

This topic was automatically closed after 30 days. New replies are no longer allowed.