Kelly, just a few other things to look at before installing a new router.

In step 1 of 7.2, they say to insert the router as far as it will go. Well, there is not a shoulder on the router housing to sit flat on the router mounting block. I would suggest inserting the router as far as it will go then lifting it up 1/16". This will insure the mounting block bore comes in full contact with the machined portion of the router housing. On a Dewalt, you may have to lift it a bit more due to the amount of radius they machined on the router housing. In any case, you want a cylinder to cylinder contact only.

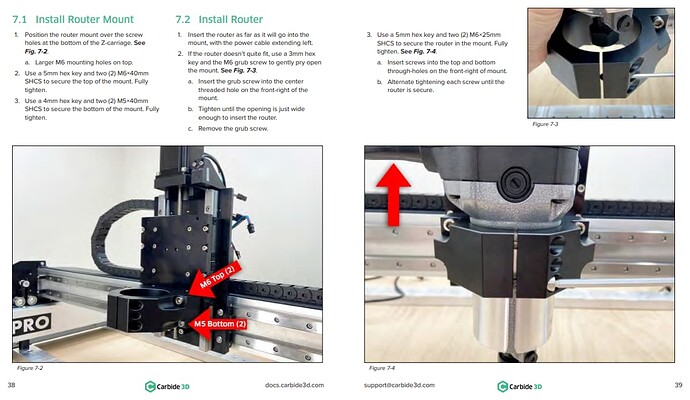

In 7.2 Step 2-C. Remove the Grub screw. This is critical and understated.If you tightened the two (2) M6×25mm SHCS as seen in step 3 of 7.2, you may not be clamped on your router housing securely and damage may have been caused to the router mounting block.

In 7.2 Step 3. They say “Fully Tighten”. I know not everyone has a torque wrench in the tool box but it would be great to have a torque spec here. If over tightened, it could crush the router housing enough to cause bearing issues.

As you tighten the router mounting screws, compression forces go toward the center. The hoop strength of the router housing is a lot less than those two screws can apply.

I hope this helps.