Asking for help, I am new owner /user of a shapeoko 5 pro 4x2. I downloaded a file from cutrocket.com for a simple bit try for carbide. I’m certain I’m zeroing out z correctly by using the paper trick. I am starting to wonder if there’s a problem with the file. When I run the project, it runs the program about 3 inches above my material. I am using carbide motion with a corner zero, file is attached.

65eea6ae243f1_65eea73d62e7b.c2d (124 KB)

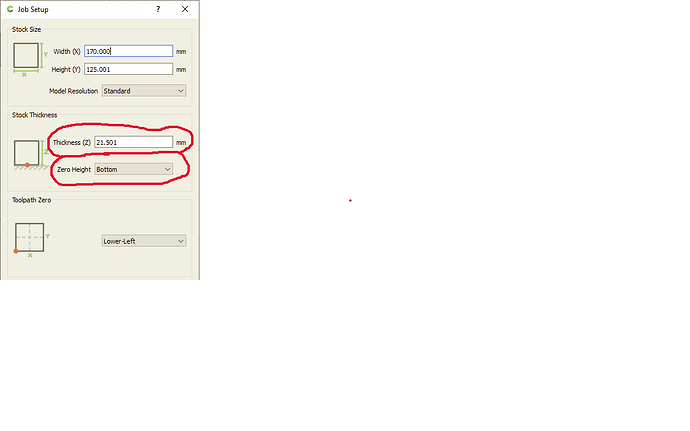

This file has the Z zero as Bottom of Stock. Are you zeroing off the bed? Have you adjusted the file to be the same thickness as the stock?

If you are actually zeroing off the top of the stock, I would just change the project to match. It’s under ‘Setup’.

As @mhotchin noted, this difficulty is often caused by a disconnect between:

https://carbide3d.com/hub/courses/create/job-setup/

and how origin is set relative to the stock:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

Michael,

Thank you for helping me out , I made the change and the machine ran perfectly. This won’t be my last ask for help as I get to know the machine a little better and I progress with it. But agin thank you!

Some the CutRocket files are version 6 or 7 or 8. Older versions may need to be opened and resaved in the next higher version to work. As noted the 3D files earlier than V8 will need to be converted via a different process or re-designed.

Personally I use bottom of material for about 90% of my projects. By using bottom of material I do not have my spoilboard hacked up. Either top or bottom measurement of the material is important. Maybe more important on bottom of material because you dont have an onion skin left and the hassle of removing the onion skin. If the material is thicker than you tell CC the first cut will be a little bit more than the parameters from the F&S. That is not likely to be a problem with normal cutting parameters but if you are agressively cutting deep cuts the first cut will be deeper than you anticipate. With an so5 it would not likely be a problem. The rest of the cuts would be as programmed.

The only issue you can have with using bottom of material is if you like to verify positions with rapid positions you must jog off the material to a clear space before issuing the Z+6mm or your bit will run into the material. The Checking of the X and Y will not cause any problems but the Z+6mm could be problematic if you are in a habit of checking that after using top of material.

This topic was automatically closed after 30 days. New replies are no longer allowed.