The machine is connected straight to dedicated outlet with power cable that came with the machine

Please contact us at support@carbide3d.com and we’ll do our best to work out what’s happening here and how it should be handled.

I’ve opened a case on Tuesday morning, so far I’ve been asked to check some screws and take another picture of the machine.

So apparently the sound you hear in the video I posted is normal and it shouldn’t affect anything. According to support I’m good to go.

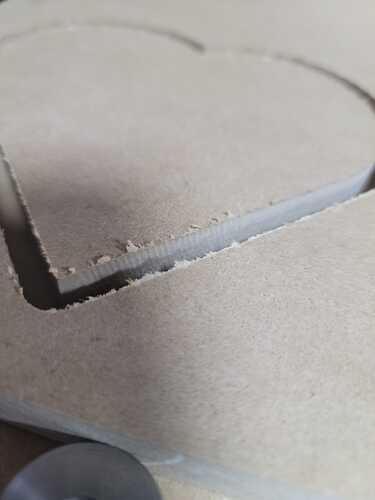

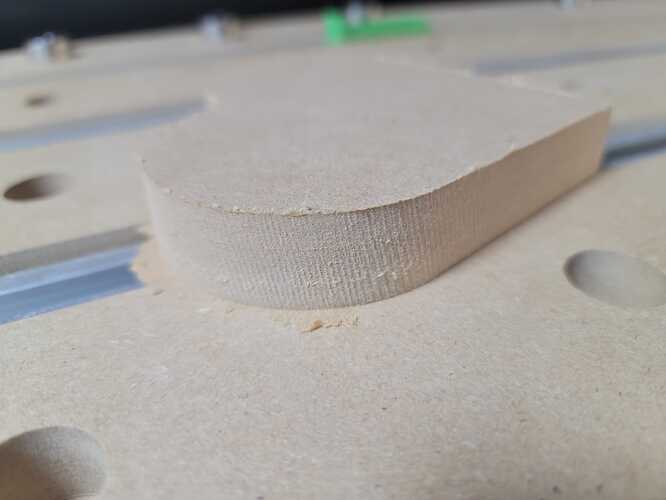

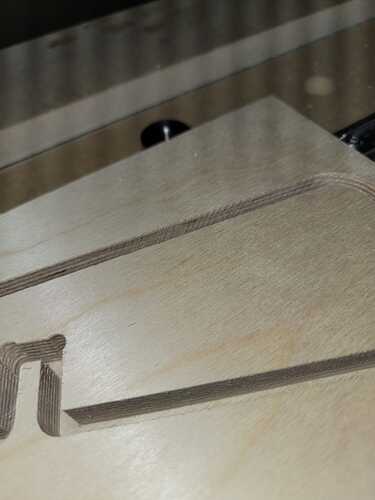

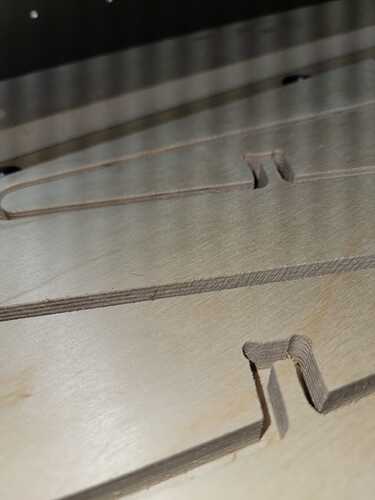

This is the cut finish I get in MDF at 75IPM, 0.25 DoC:

And in hardwood is even worse.

My old SO3 was able to cut faster and leave perfect finish…

Would anyone with SO5 4x4 be willing to take this test pattern run it at 200IPM on your machine in mid air and post a video of it so I could compare the sound?

SO5 Test.dxf (7.3 KB)

Try changing the speed at which you are running. Increase / decrease by 20% and see if the noise changes or goes away. Are any of the steppers getting hot after a short run? Are you running the lastest CM? Have you updated the board via CM?

To me these edge artifacts look like a result of a high feed rate and relatively low rpm.

I tried at different speeds, went down from 200 IPM down by 10 IPM, at about 50 IPM the noise seems to be almost gone.

Steppers don’t even get what you would call warm.

CM-579

Newest firmware

The weird part is the noise and vibration only happens when machine moves at 45. Even when testing in Rapid Position the machine is super smooth unless I tell it to go between two points at 45 from each other, it seems to go away at above 60 to X or Y axis.

The cuts in the picture were done at 75IPM, 0.25 DoC and 18000 RPM with #201 brand new end mill

The frequency of the vibration lends itself (at least to me from what I hear) to be a small metallic part that is not quite in full contact with another. The primary frequency seems to be right around 440 HZ with a couple secondaries above that.

Try pressing down on various parts of the machine / bed as the noise presents itself to see if it changes. If you find an area where applying a dynamic load changes the resonance you are getting close to to the loose component. Also, for fun, you can dump a bag of rice on the bed and watch for cool patterns.

I’ve had those same looking artifacts in MDF when I was cutting hard…not too far from where the spindle would stall. But I have been in the habit of finishing passes for years, so I got them smooth that way.

I’ll give that a try tonight. But if its a loose part (and ive checked every screw i could find) then why is it quiet and smooth when parallel to x or y and at angles outside of 45 to 60 degrees.

I hope 75IPM in MDF is not considered hard for this machine lol

Depends on the depth of cut. ![]()

This was cut at 100IPM, 0.125DoC, 18k RPM and new Nomad #201 endmill. I even tried decreasing the speed to 50IPM but the chatter got even worse.

I really wish I wasn’t such a fan boy and did more research before buying this machine, for not much more I could have had a real Pro CNC machine, with pro version of stepper motors and pro version of control board, and I would have had saved some money by not having to buy a computer to run the machine. I’m sorry but there is nothing Pro about Shapeoko 5. If Carbide3D would let me return this machine I would not hesitate.

Are you using a router?

Sorry don’t have much help to offer but just wondering if the noise coming from a particular place/source? Might help narrow down. Doesn’t sound ideal for sure. Sorry to hear you’re having troubles. I can’t remember from all the posts above but assuming you already made sure the rails were parallel/square to each other?

Using Carbide3D VFD spindle

I tried several times to pin point the source of the resonance and it doesn’t seem to have a spot that I could hold down to reduce it. Yes the machine is squared to within fraction of a millimeter over the width of the cutting area. I do believe its electronics related as the machine moves very smooth if I disconnect the steppers and move it by hand, no binging anywhere. And yes I already oiled everything that accepts oil.

That sound is not normal. I agree with the others on this form it sounds like possibly a loose coupler, or possibly a bad linear rail block. Would also be curious to see what the underside of your table looks like. I had residency issues with my beaver HD pro frame kit. In my case, the under structure of my table was not rigid enough and so the table top flexed under the weight of my machine causing the frame for twist ever so lightly.