Hi all,

Finally getting around to setting up my SO5 Pro 2x2 after it’s been sitting a couple of months. For a spindle I have a PwnCNC 1.5kW water cooled spindle and the VFD they include (it’s the ‘generic’ Huanyang model, before the fancy enclosed yellow/black units they sell now). I am mostly set up but am stuck on one last thing.

-

I first wired the spindle to the VFD. Everything is OK there and I can manually control the RPM from the VFD panel, so I know the spindle is all good.

-

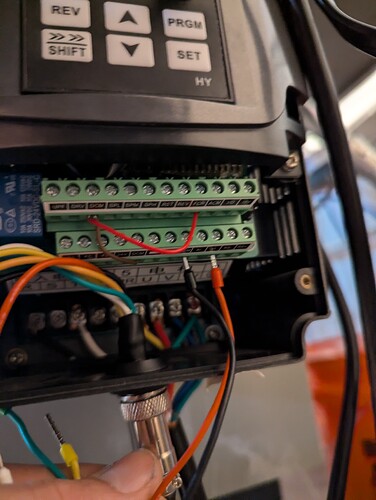

Next I connected the PwnCNC pigtail connector to the two ISCP pins inside of the controller and the coordinating wires to the ACM (ground/black) and VI (positive/red). I know this is working, the correct voltages can be read at the terminals (e.g. 5V with M03 S24000)

-

Mostly following this thread I set up the parameters for the VFD. If I set PD001 = 0 I can stop and start the spindle with the VFD control buttons and send RPM commands via the CarbideMotion MDI. The spindle responds accordingly. My issue is that regardless of the PD001 setting (which should be = 1) I can’t get the spindle to stop and start with M03 / M05.

All of my parameters match the thread linked above (with the exception of the motor specific things, e.g. mine is 110V not 220V). This isn’t the first time I’ve programmed a VFD spindle either so everything else passes the smell test.

Anyone run into a similar issue or have some further troubleshooting steps?