Yeah, I had Vcarve desktop 9.5 and pro AND v10 of both - all four working without interfering with each other. Not yet pulled the trigger on vcarve desktop … but I suspect it won’t be long. Lol

No problem see pics Does this answer your question?

Im on my computer 90% of the time as im finishing college / making things in my diy CNC wood shop so lemme know if theirs anything else I can help with. Trying to get some macro video tutorials going soon.

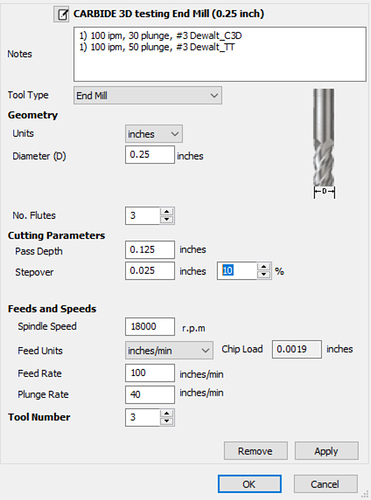

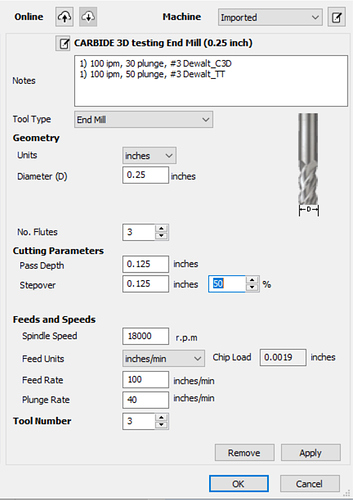

Thanks for checking that for me. So it seems v10 does not account for chip thinning in the calculation. No big deal, I would have been surprised if it did (even Fusion360 does not do it…), I guess I’ll continue to use the spreadsheets

It’s still a good thing to be able to double-check chipload at a glance in that menu.

Manufacturer’s chipload recommendations don’t either. ![]()

2019-09-24 Update

@Julien This HEM Guidebook says that “chip load” is defined only by feed per tooth (IPT) at RDOC = 50% cutter diameter, whereas “chip thickness” reflects the impact of chip thinning. Since that makes sense to me I’ll change the SFPF Worksheet accordingly.

Yeah this other source also states the “chip thickness” is what you get after thinning, while “feed per tooth” is the thing computed at 50% WOC. I’ll make a note about this in ebook v3, not that I think it matters much as long as people understand the two concepts, but using the “right” words is preferable indeed.

It’s actually the same source. But, unfortunately their HSM definition seems to differ from the “classic” definition - assuming there is one!

Looking at buying some endmills, I came across right-hand and left-hand endmills some are upcut while others are downcut. Since our routers are going clockwise or right, most of the endmill are right-hand but when do you use left-hand? Do you need a left-turning spindle? This was not addressed in @Julien current version E-Book. I looked on-line but I found the info confusing. Maybe this is something @gmack has previously looked at.

Beats me - maybe asymmetry in the machine’s performance? HF spindles can run in either direction, so they can use either type. But @VikingVoyager said he wants to be able to reverse his router’s rotation direction for reasons I don’t quite understand. Maybe he can explain/elaborate!

This is the discussion I found on the subject but I can’t say I was clear on the issue after reading it.

Some there seem to be “talking” about bit rotation directions to others that are “talking” about spiral rotation directions (i.e. upcut vs. downcut endmills.).

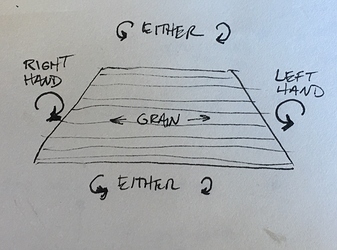

I work in hardwood, and depending on the angle of the cut regarding the grain direction, Left Hand leaves a clean cut vs Right Hand. See the drawing…it shows what rotation you need to give you a clean cut.

Imagine if on the right end of this piece, instead of using a Left Hand mill, you use a Right Hand mill, the Right Hand mill would lift the grain and tear it out on a micro level…where as the Left Hand compresses and sheers off the grain rather than lifting it.

Imagine slowly feeding your finger tip into a table saw blade, as if you’re pointing at the blade from in front of the table. The blade will push down on your finger nail and cut it. Alternatively, if the blade was installed in reverse and the motor was run in reverse, the blade would lift up your fingernail before cutting it, and most likely separate it from your skin. Think of end grain like your fingernail. That lifting causes what I call microfractures, and it will require some sanding to get below the microfractures into ‘clean’ wood. You can save yourself a bit of sanding if you use the appropriate Right or Left Hand cutter for the given direction. It certainly requires more toolpath setups and tool changes, but the results are worth it.

Your sketch shows the grain perpendicular to the cutter on both the left and right sides. So, why would the cutter rotation direction matter?

I’m pretty sure it’s because the wood will chip along the grain if the cutter is going the wrong direction. This happens regularly to me with my makita on my xxl.

Cheers

Jason

I can see that happening when milling either faces or edges of boards where grain structure/orientation matters. That’s why direction matters when feeding some woods though jointers, planers, or shapers where the cutters might tend to lift/rip/tear-out rather than cut the grain. Unlike routers, shapers have reversible motors. They use higher power and lower speed motors to support (scarily) aggressive cuts with large cutters which increase the likelihood of tear-out.

Fortunately, the feed direction of CNC routers can be reversed if necessary to compensate for problematic edge grain structure/orientation if necessary. Less aggressive cut depths and/or widths, higher spindle speeds, and increased number of endmill flutes should also help.

Here’s a dope video that seems to support my claim that woodworkers using CNC Routers should be “making dust not chips”.

Cool video, but that helical cutter at the end is making lots of chips and not much dust. The thread has gotten really long and maybe the references are in different posts, but can you briefly explain again your “making dust not chips” theory?

With the exception of woodworking power tools that are used to remove lots of material fast, like jointers and thickness planners, that’s what the tools have been doing for decades. The only explanation for having CNC routers do otherwise seems to be that “chips are necessary to remove heat”. IMO that makes absolutely no sense. Thanks for asking! ![]()

Hi Julien,

Thank you for all the amazing work you have put into this project.

I am teaching an intro to CNC class/workshop next month for my local makerspace and as we are in a somewhat remote location i.e. many folks have little better than dial up I was super stoked to find your ebook that I could hand off on a drive and or print (for those of us that study best with a dead tree in hand) as the syllabus class.

And when I printed it up and started in with the highlighter about half way through I was seeing double…

ah must have been an issue with my printer or my eyes…

Anyway it looks like at page 161 - 162 on the PDF and page 342 - 343 in the ePub the document starts back in at beginning with CNC workflow, and does not show any new content until page 320 - 321 ish in the PDF

as well if you are going to be going back in and reexporting your pdf for printing and or offline viewing…

A lot of the cutters and collets pictures are out of sync with their image foot notes / sub titles. eg. page 34 and page 35.

It is so amazing that you have taken this on and I am super stoked to have access to this. I am hoping to do the same with my lesson plan  when I am finally done with it

when I am finally done with it

Cheers,

- Q

Hey @Quana,

Thank you, I noticed that problem recently, and assumed no one had detected it yet

As I am working on v3 of the ebook, I figured I would fix it when I release it, but I will have a look and let you know if I can fix v2 quickly.

As you will be going through v2, I would appreciate a lot if you could provide comments (typos, obscure sentences, things missing…), I would address them in v3.

@Julien you had me at V3 lol , any ETA for it ?