This enclosure is pretty slick. Just curious, what do you do with all your machines that allows you to justify the cost involved in all the machines and building these enclosures?

I started learning CNC when I ordered my first machine, a S3XXL in November of 19, and really enjoyed learning on it. I previously was a game designer in the 90’s and my modeling skills were easily transferred to CNC, and after winning 5 contests on here, I started to think I had found a rewarding and creative path forward that is a good fit for me.

The pandemic caused me to re-evaluate my tour boat and jet ski rental business, which was also very rewarding but stopped being viable as soon as the pandemic occurred. I decided to start building a 3D printing and CNC studio in my home. I sold off some unused assets, and used some profits from crypto-mining and decided to invest.

Enclosures allow me to run multiple machines in my home with sound contained and no mess. Imagine running 6 machines at once in one area of your home with no sound or dust containment. When I am done building all my machines, I will concentrate on building websites, and then designing and selling my creations.

I have a penchant for customizing and designing/creating then building things, so all this is fun for me.

Best part of it all is to use your imagination to create something on the computer and then turn it into something real.

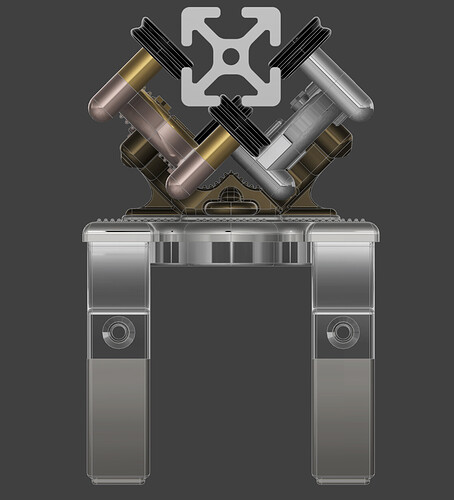

Obviously I haven’t seen the other side of the trim pieces, but they almost look like extrusions? Mold making of that size is cheap if you do silicone and cast the parts. The nice thing is you can pop parts out every 10-20 minutes, and make multiple molds to get through parts even faster. For big pieces like that I also add fillers which reduce the cost of the casting even further.

If printing is working well for you no real reason to change, maybe a decision point if you end up needing higher volume. I haven’t done plastic extrusions, but I know for an aluminum extrusion a custom die is ~$2-3k investment.

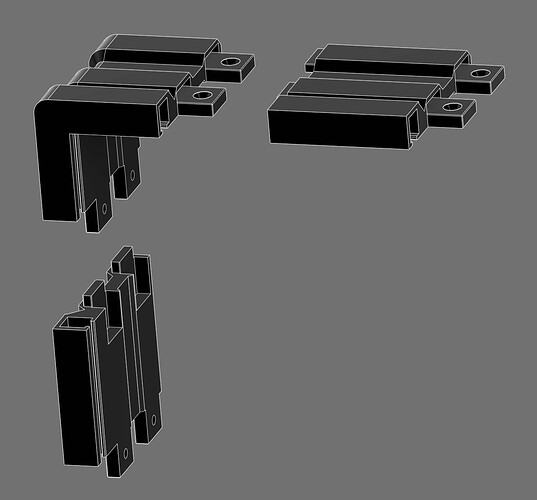

They interlock and each piece bolts the top section of the enclosure to the bottom, with flat head countersunk bolts and t nuts, and the ones that need it have a wire channel to hide cables.

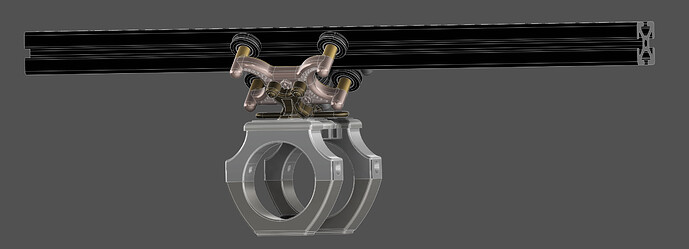

If I were to invest in a mold, I would probably start with my hose trolley setup, which works very well.

Nice! Obviously the corners are different, but the straight sections are definitely extrudable. Basically you would have a single die, extrude whatever length you need, and then post machine the little end interlocking features. You would need a lot less of them of course because you would make long lengths.

One advantage to the shorter lengths is multiple interlocking connections from the top to the bottom, absorbing vibration and keeping it secure plus they are bumpers! Yes occasionally I smash my enclosures into each other lol oops, and no damage!

Extruding lengths would allow you to form the convoluted T-Slot shape, an injection moulding tool would become very expensive if trying to do this (sliding tool features), or by-hand inserts inside the tool cavity to avoid the costs but at the expense of increased labour. If the strength attained with 3D printing is adequate for their use, then low injection pressures/shot volume etc for a mould tool would possibly bring this within the realms of a desktop/hobby machine and soft tooling (eg: aluminium)

He’s retired and enjoying the fruits of his hard work.

This is hands-down the best enclosure I’ve seen on this forum. Well done!

Thank you Ken, a lot of work and is very gratifying to be able to use it after spending so much time building it. First one is almost finished, working on magnetic door stops and dust collection for 80mm spindles with additional power and water hose attachments and that’s about it for my plans (So far). Building the models for everything has been a long tedious process, but easy to reproduce for other enclosures.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.