Any plans to update the HDM gantry to allow the spindle over hanging “for jointrey” as the Shapeoko 5 Pro?

I don’t think that’s something we’ve considered — it would fly in the face of the rigidity which is the raison d’être of the HDM.

What sort of joinery do you wish to do? In what material?

For my part, while I tried this out rather thoroughly:

I find doing such designs tedious — at a minimum one has 3 setups:

- cut the parts to length/size

- mount all four boards and cut joints into two corners

- remount all four boards and cut joints into the other two corners

It’s a lot more workable and flexible and convenient to just cut the parts to size and cut the joinery all at the same time:

I’ve been working on a full-blind technique which has been working out well in test cuts/files — hoping to have a finished project presently.

If you’ll provide the specifications:

- box size (height, width, depth)

- stock thickness

- box features (what sort of lid, any hardware — include links to a 3D model of the hardware)

I’ll gladly work up a step-by-step tutorial on how to design it.

I think this might be the first request for this. I have removed one of the hybrid table slats but a spacer like @Tod1d points out would work.

I will note it down mind.

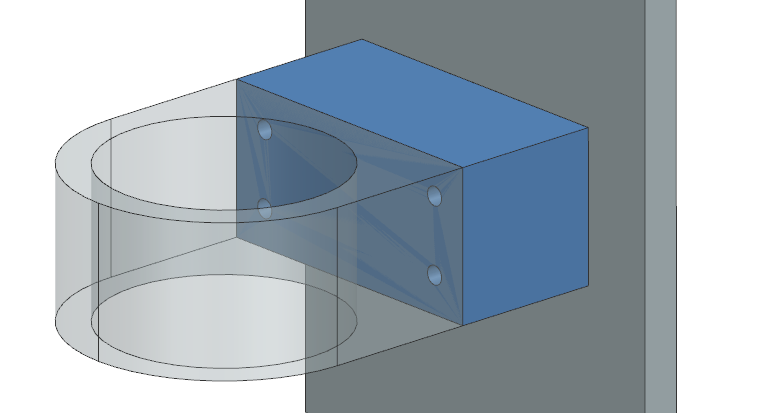

I will post some pictures of my installation of the rotary on my Laguna iQ when I get back home”I’m out of town”, but to give you an idea, I installed the rotary in front of my spoil board. I used a 12”x48”x3/4” aluminum sheet and bolted the rotary and the tail stock on it, made a jig to make the aluminum sheet as a front extension to the spoil board. The gantry on the iQ Pro can move about 12” in front, overhanging the machine front edge.

This topic was automatically closed after 30 days. New replies are no longer allowed.