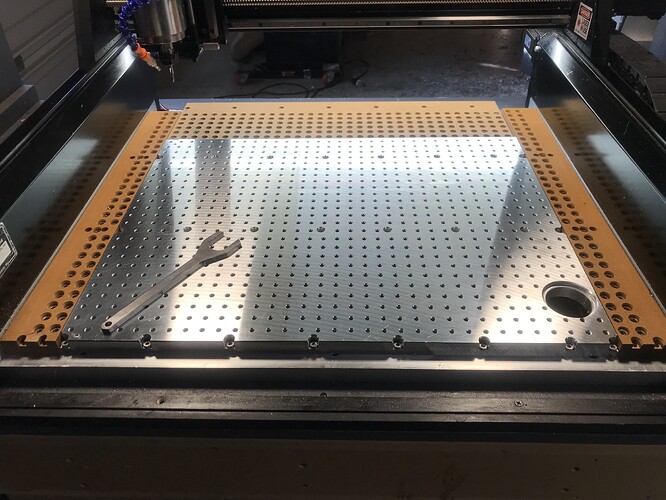

Anyone here have the full set of Saunders Machine Works fixture plates for their HDM (link)? If so, how did you attach the Shapeoko Pro Bitsetter that came with the HDM? I had to remove the hybrid table to attach the three SMW fixture plates, and Carbide 3D’s manual for the HDM has instructions for installing the BitSetter HDM around the T-track slots in the hybrid table. Is there an optimal way and spot to install the BitSetter on the SMW plates?

I messed around a bit with Bitsetter location when I first setup my HDM. Left, rear corner, center rear etc. Also several iterations of spoil boards, hybrid table mods and so on.

I ended up simply placing the Bitsetter on the right, front corner of whatever work surface I had in place, not bolted down, so I could easily remove it from the work surface if circumstances demanded.

Then I saw a clever innovation by @CNCInspiration and incorporated it into the fixture plate I eventually ended up with.

Sorry, it’s not installed in the pic but when in place it sits a few mm below the surface of the plate.

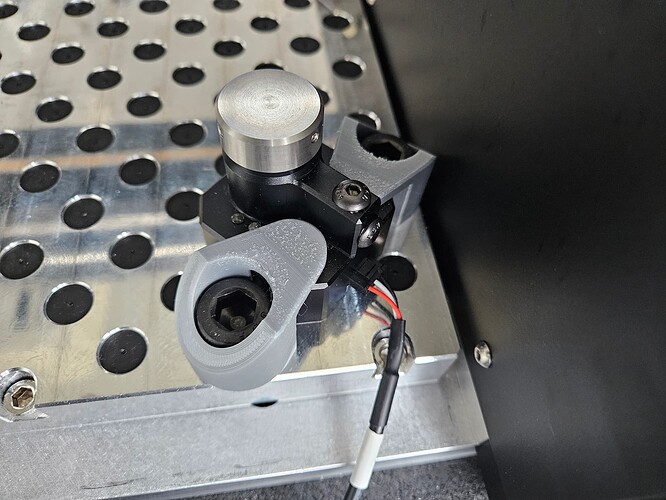

I modeled up and cut a holder for mine. I asked several people how they mounted theirs and never got an answer so i just did my own thing.

I designed and 3D printed a bracket to hold my Bitsetter in the right corner. The bracket has bosses that fit into the original holes for screws on the top of the Bitsetter and mounts to the plate

with 1/2" socket head screws.

Looks like you removed the t-slots and mounted the fixture plates directly on the frame cross-members?

Curious if you had to mod the SMW plates to get them to bolt down to the frame? Any issues running these plates this way, any issues you ran across by doing so? Really like the perimeter fence, btw!

Making my own plates and going to do the same on my SO5. Mainly for extra Z height but also for clearing the tool setter since it mounts to the y-rail t-slot.

The plates I got were made to be bolted right to the frame with 40 m6 bolts.

I diddnt like the idea of losing rigidity bolting them down to mdf and aluminum channel and I diddnt like the idea of the smaller plates they sell because im running 10mm endmills at 30m^3 + mrr and the half inch mod vise fit my use case better then the 1/4 inch one. Be prepared to do some shimming to your axis if you want to maintain accuracy. My x axis was 16 thou deviation side to side.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.