Hi all.

I have a Skapeoko Pro Standard and so far so good… but …

I just bought 2 fixture plate from Saunders Machine Workshop. Each is 300x300 mm … unfortunately they don’t fit in my Shapeoko Pro side to side ! (I plan on buying 2 more soon to fully cover the cut area).

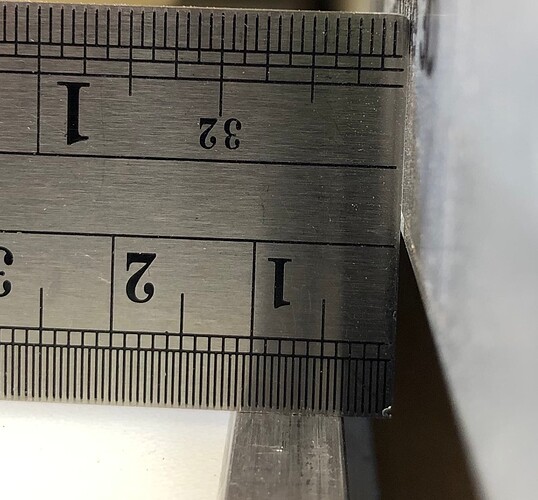

I measured the spacing between the 2 Y beam, and sure enough it’s almost 2mm shy of 600mm.

Does this mean I somehow mis-assembled my Shapeoko Pro. As far as I can tell the machine is squared 9I had another post about my initial issue and how I squared the machine ( Shapeoko Pro Standard gantry seems to not be parallel to hybrid table - #9 by rpineau ). Since that fix I have not have any issue and the machine cut square (at least for what I have done so far).

So… do I need to take it apart again, install the plates and then somehow make the beam fit on the side of the plates and re- square the whole thing ? (I feel a ‘yes’ coming ![]() ).

).

Has anybody else run into this issue ?

Thanks

From the SMW product page:

For 4 series machines, metal chip covers may need removed to accommodate plates in certain orientations. Fixture plates then act as chip covers in place of those removed. Standard size Shapeoko 4 machines may require slightly bending chip guard mounting tabs out of the way in order to fit full set of four plates (see photo).

Could that be it?

This is for Shapeoko 4, there is no “metal chip cover” on the Shapoko Pro (as far as I can tell).

But thanks for checking ![]()

You have the pro? You mentioned both pro and 4 in your original post so I guessed…

You can email SMW and ask them. I have had great support from them when asking for help (even though it was self proclaimed “my fault”).

Can you post a picture of your machine and the plates? Even though I have a Pro XXL, and looking at Saunder’s website, I can’t see what your problem may be.

Sorry Chris, yes it’s a Pro (I fixed my post, it’s been a long day).

I have emailed SMW but it’s the weekend so I’ll probably get some info on Monday.

And the plates are certainly not at fault here ![]()

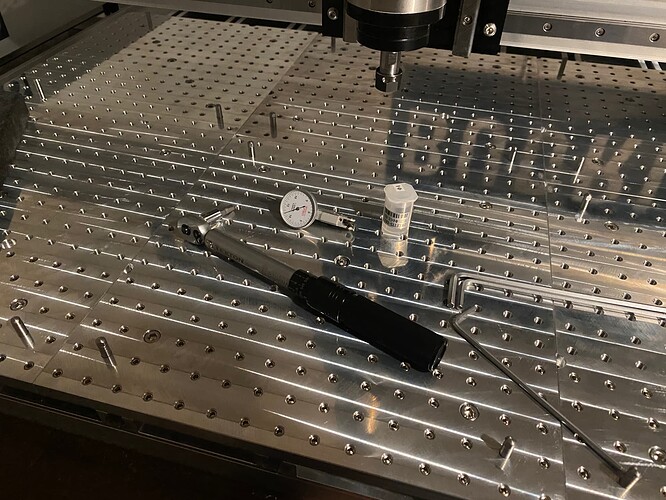

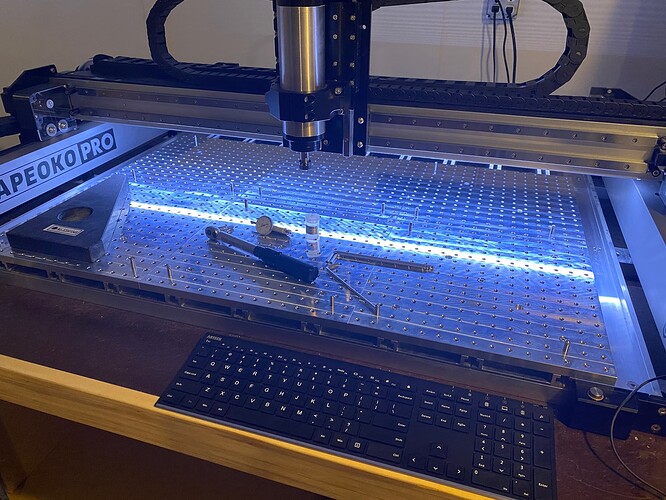

Here is what it looks like :

And with the “new” HDPE slates :

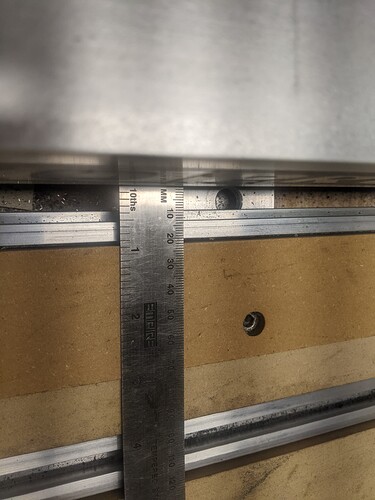

Here’s a picture of the distance from the beam, to the first slat on my Pro XXL. It doesn’t appear that your Pro standard has the same margin. I myself would just trim a quarter inch off of the outside edge of each plate, and get some work done .

I see a lot of fixture pins in your photo so as a big mod vise fan with 4 sets myself. I highly recommend getting high power magnet hooks to stick to the clamping bolts to give yourself something to pull up evenly on to get them back off the pins much easier.

I use a set like these

It is fun sometimes to get the mod vices off. In those pictures I used the pins to square the plates to the machine as I often bump work up to them to ensure squareness. Appreciate it!

Sorry you’ve had these issues but happy to get to the bottom of this. We haven’t seen this issue with a standard size yet.

Two plates should be right on at 600mm. Even still, that sounds like it would be a very tight fit on the standard size.

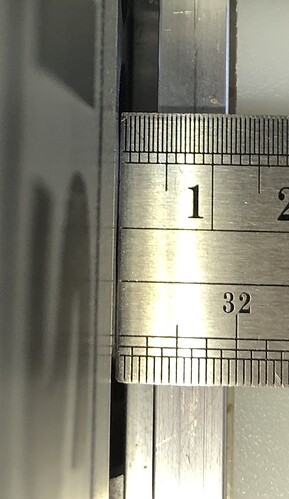

Would it be possible to get a measurement like Steve.Mc had? Distance from the side extrusion to the T slot extrusion.

Hi Vince (I assume you are the Vince Alex from SWM was referring to in his email to me ![]() ).

).

Thanks for chiming in.

I’m not at home right now but will be able to take the measurement latter in the day (West cost so this evening for you).

In all case looks like I’m going to have to loosen the bolt holding the beam to spread them a bit and fit the plate. I’ll probably bolt some metric 25-50-75 block (or bigger ) on them, flush to the edge to male sure the beam are then square to the plate.

Unless you have another idea ![]()

Thanks

That’s me! I work remote every other week and took some time to go through all the measurements to see if there was something up. I am really interested in that measurement because we haven’t seen this issue with the exception of once when they first came out. That situation required the small Y axis chipguards to be unbolted and removed but was fine after.

If the plates can fit with just a little loosening then they should square themselves up pretty well to the Y axis extrusion themselves and we have a 3d printable alignment fixture that would also help. I recommend sweeping the front of the plates during install to make sure they are lined up as well.

It looks like your standard pro doesn’t have the guards so I would be very interested if the extrusion to T slot distance is different compared to the XXL/XL. Sorry for the hassle, but we’ll get down to the bottom of this!

Thanks Vince.

I 3D printed the alignment tool for the plates.

As the T slot are bolted to the bottom frame with countersink holes, I would assume that they are forcing the bottom and T Slot to be squared. This doesn’t mean the distance is the same indeed. I did look at that after @Steve.Mc picture and there is definitely less space than the 9mm or so he has. More like 3 to 5mm but I’ll have something more precise when I can do the measurement latter in the day…

Thanks

Vince,

I ordered 2 more plates so that I have all 4 in hand in case I need to disassemble the Shapeoko Pro to install them (I was planing on starting with 2 and then adding 2 more, but having all 4 now is a better option due to this fitting issue).

Thanks.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.