Thanks for the photo. That really helped!

I’m not sure I understand this fully. Can you expand a little on the issue?

Here’s videos of my latest issue. And, it’s beginning to make me feel like I made a bad decision with this upgrade.

The videos from top to bottom are various increasing speeds with the sandy or weird noise I’m hearing. It didn’t start make this noise until after my first cut. I thought it was the collet that came with it but it’s definitely coming from the spindle.

The last video is from 20k rpm to m5 command. And, this one really has me frustrated a bit.

Do you guys think this fixable but a parameter?

Or is this spindle a dun?

I’m so frustrated.

This GPenny 800W water-cooled spindle with co-supplied VFD (Huanyang if I recall) is what I have, and it is really very impressive. I don’t get the ‘sandy noise’ you describe, but for a short while there was some noise from the spindle that concerned me - it disappeared very quickly and hasn’t returned. Various people have referred to ‘warm up’ routines at every workshop session to get the bearings settled, I have done that and on occasion not and (so far) it doesn’t seem to have had any adverse effect

Is the water flowing? It doesn’t take much for heat to kill these things, from what the documentation says anyhow.

I was paranoid about water flow when I installed my g-penny so made sure I had a flow indicator in there to make sure the pump was pumping.

Yes. It’s flowing. It’s not warm to the touch. Sounds like an aircraft warming up.

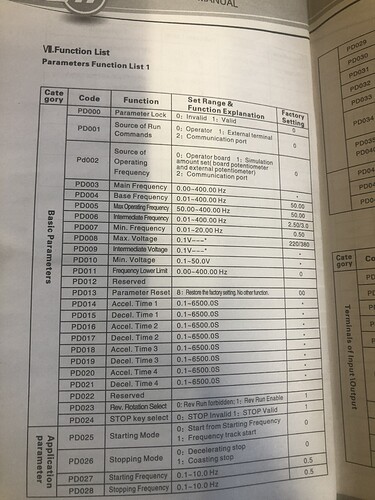

here’s my parameters for what its worth

01=1

02=1

03=400

04=400

06=3

08=110

09=7.5

10=4

11=100

70=1

72=400

141=110

142=7

143=2

144=3000

I’m doing a warm up session now. and, it sounds like radio noise or interference sound from the spindle…just weird…if thats normal than i guess i have no problems… i need to maybe hear someone elses and compare

Pd 14-21 increases start up speed. I think I need mines faster to be able to use the spindle control function properly for automatic control. For now I’m leaving it off because the spindle doesn’t get to full speed by the time it reaches the workpiece.

What settings are you guys using to increase spindle full speed?

Quite a comprehensive write-up on this from @Julien in an earlier thread;

I have a YL620 VFD which is different to yours. I just left the start up speed parameters as they were.

This topic was automatically closed after 30 days. New replies are no longer allowed.