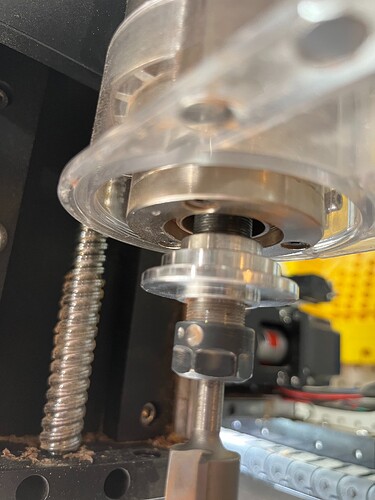

I am not sure why this is happening but I thought I would reach out. I have used the spindle for a few months with zero issues. Lately I have noticed ONLY when using a bowl/tray bit 3/4 inch that the bottom piece is unscrewing on its own. I tighten it back up by hand and continue to use - does anyone know how to fix this issue?

The trim routers are very susceptible to vibration. The longer or the bigger the bit the more runout and the more vibration. Since you know your collet nut can come loose then try and pause and re-tighten the big every few minutes.

Just to be clear the Makita/C3D router requires two wrenches to get a good tightening. C3D recommends you use the lock button and one wrench to get the bit tight enough to keep it from dropping out and then using two wrenches to tighten up the collet nut to the router shaft.

Also make sure your collet and collet nut are spotless. I use brake cleaner to clean out the collet and nut on my router. Then use a qtip sprayed with cleaner to clean the inside of the router shaft. The collet nut and collet should be dry and lubricant free.

If this continues to happen using two wrenches then consider replacing the collet. C3D sells replacements but elairecorp.com sells them as well and they come in both SAE and metric sizes.

This is a spindle not a router. Talking about 2 different things here. Anyone that has the spindle has this happened to you?

Open to suggestions - Thank you in Advance.

I have not had that happen to me, but I also don’t use those bigger bits. I’d be inclined to reinstall that nut with a little locktite on the threads. Be sure check the spindle shaft for side to side play.

That nut looks like it could be part of what supports the lower portion of the spindle shaft in its bearing. If that’s the case, using those big tools with fast feedrates could possibly have deformed that nut in a way where the spindle shaft is not supported on it’s center line. That may be why it’s coming loose.

Just an observation, but it looks like an awful lot of bit shank sticking out of the collet. May try inserting the bit further to reduce vibration. Are you getting chatter or hear much vibration while running or as the spindle winds up?

When I had a trim router, I got used to cleaning the collet taper and collet after every job. Tightening by hand was easy enough. Now I have a spindle with an ER20 collet size. It is harder to judge the amount of tightness by hand and it needs a whole lot more leverage to get the collet clamping nut tight. I opted for using a torque wrench and known torque settings.

This gives me confidence in the tighteness of the collet. I use high quality collets (5 micron TIR) and ensure that the bit is held by the whole length of the collet. Your picture shows the bit with a lot of stickout and if it is possible to reduce the stickout without butting up against the collet taper end, this may help. Has the collet nut become worn/distorted? Cleaning collets after every job should assist you to be sure there is no debris keeping the nut from clamping the collet correctly.

Torque settings for my collets are 32Nm for up to 1/4 inch and 80Nm for 1/4 to 1/2 inch.

For those trying to help me out I greatly appreciate it. The issue I am having is not…

Router issue - this is the Shapeoko spindle

Nut issue - it is the silver piece in the screen

The bit is perfectly tight however while using a 3/4 bowl bit the SILVER piece unscrews on its own and lowers itself to the large not.

The only way I have to tighten the SILVER piece is by hand.

I am trying to figure out why this is happening. This has only happened in the last 2 weeks.

Any help regarding the issue is greatly appreciated.

I don’t have a vfd spindle, just a Makita trim router. But from poking around, it appears that aluminum piece is a “slinger”, to divert trash and stuff from reaching the bearings. I would take Ed’s suggestion of putting some loctite on the threads (after cleaning them) and tightening it back up. Your picture doesn’t show it, but I assume there are two small holes to fit a spanner wrench in to tighten. I’ve attached a video link of a spindle being tore down. https://youtu.be/6J20Cqf6VHk?si=7vDD6JhrVbjgjSFH

This topic was automatically closed after 30 days. New replies are no longer allowed.