Wow! That is impressive. I thought the XXL used the same width belts as the standard SO3. That is the 9mm Gates GT2 as far as I can recall. How are you getting such great life out of your belts? I agree the SO3 is a solid machine and for me it was a great starting point. My intention is to upgrade it with the HDZ (which I have sitting here) once my spindle has arrived.

Apart from the belts, the other really worthwhile (I would say essential after using it extensively) upgrade for me was the aluminium fixture plate, stiffener rails and the modular vices from Saunders Machine Works in Zanesville, Ohio.

The change in rigidity has been astonising and while I understand that desktop CNC machines are much more suited to the hobbyist, there is a compelling case to be made for using the super rigid SO3 to make a few production quality items. I can easily machine aluminium within a ±0.001" tolerance and with careful machining practice and a new cutter, I was able to achieve a tolerance of ±0.0004" on one occasion.

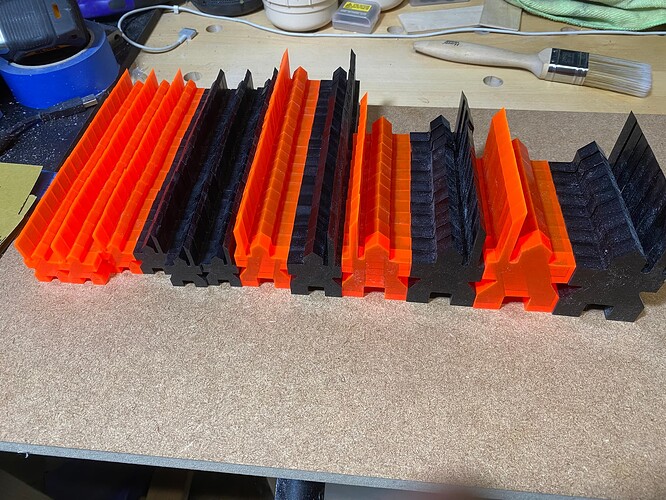

Pictures showing several different size objects in 10mm thick acrylic. I produced more than 1200 in 4 different sizes and two different colours. The client was delighted. If you look really closely at the pieces in the first picture, you will not find any reason to reject the SO3 for this kind of one off production use. I used a 2mm uncoated single flute cutter at 18,000 rpm with a 50% stepover and a 1mm stepdown for cutting this acrylic sheet.

This image demonstrates three of the different sizes and two colours

The next image shows all four sizes and two colours

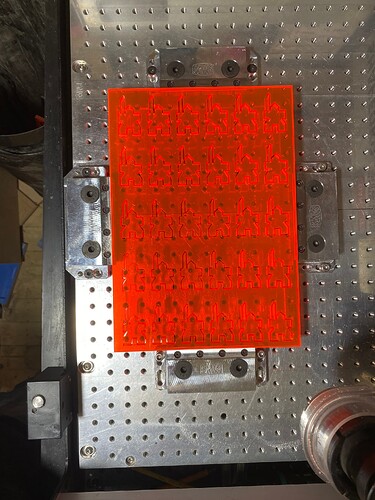

The last image shows an A4 sized (297 x 210mm) sheet of 10mm thick acrylic on my machine.